Security sealing device and application for pumps

A technology of sealing device and mechanical sealing device, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of insufficient sealing, large leakage, pressure increase, etc., and achieve the effect of excellent performance and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

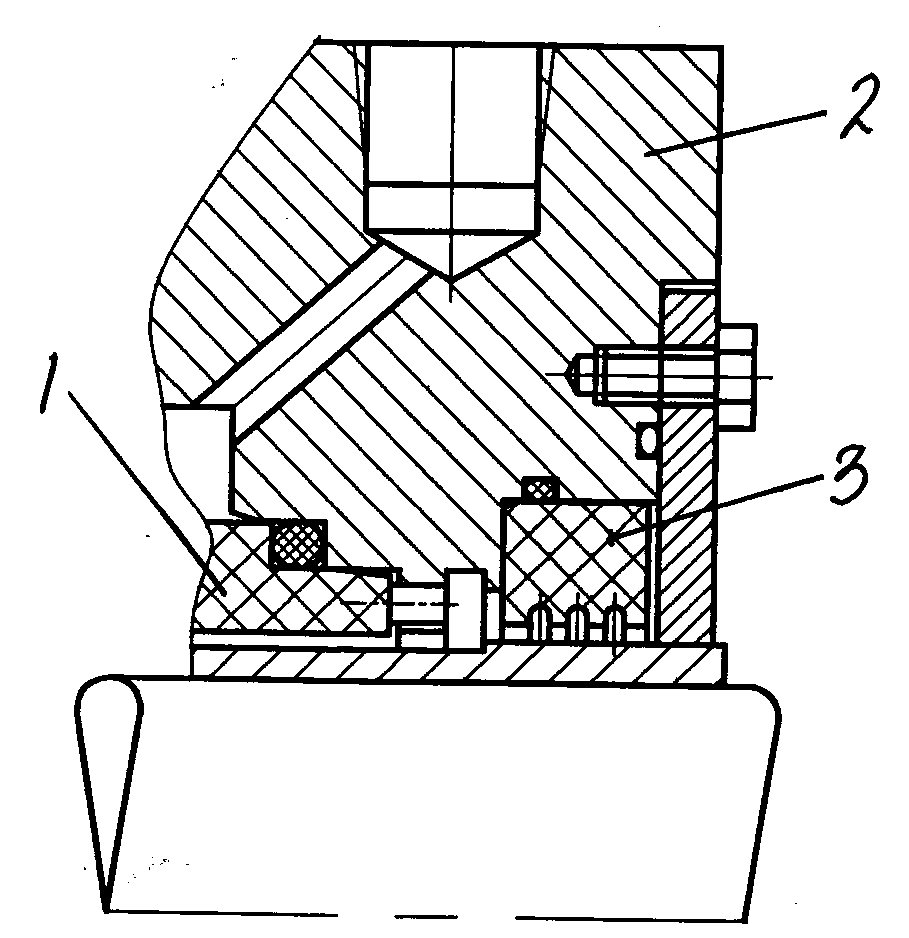

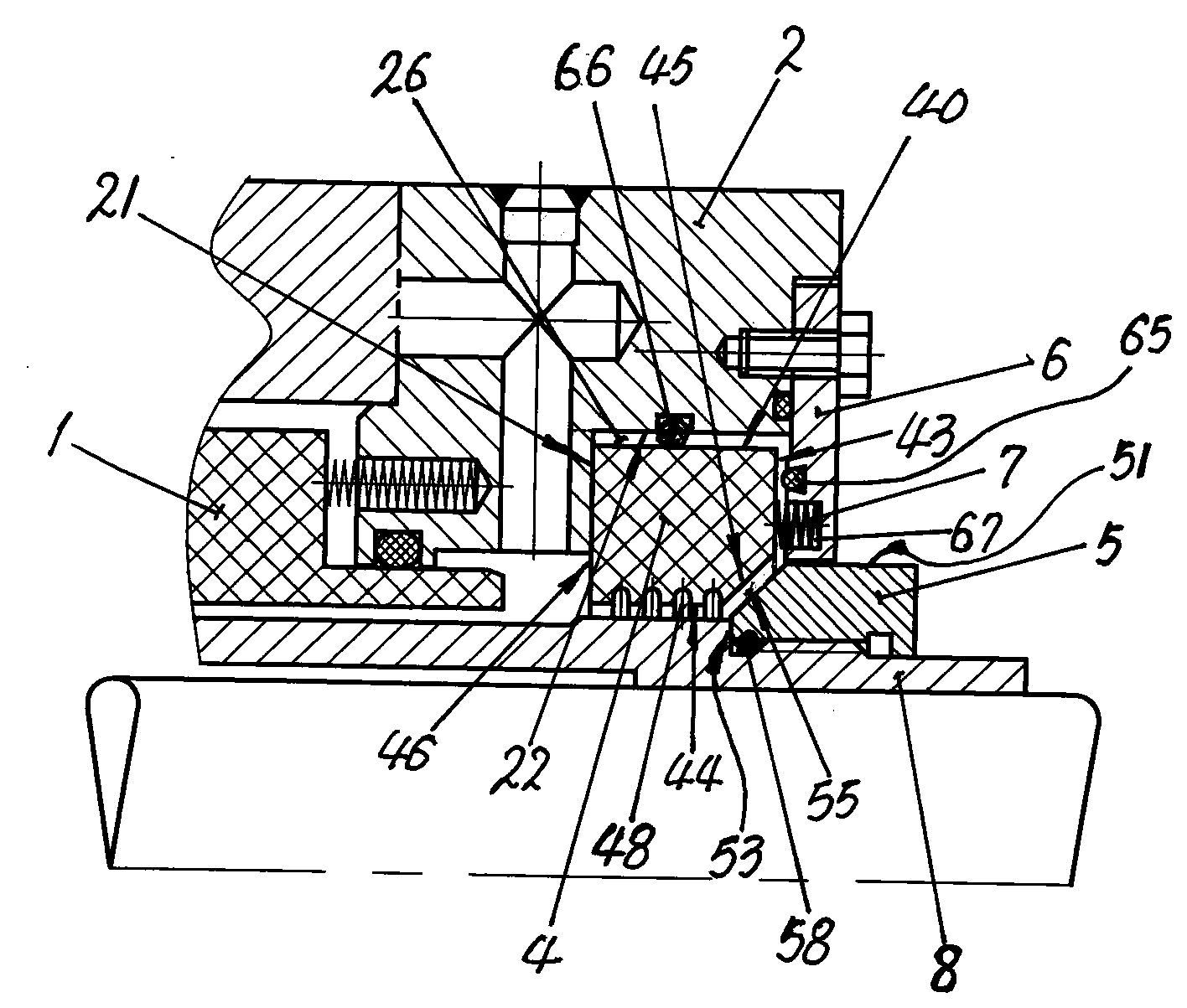

Image

Examples

Embodiment Construction

[0013] The present invention includes a gland 2, a cone ring 4, a cone ring thrust spring 7, a cone sleeve 5, and a pressure plate 6. A groove 21 is provided on the inner diameter surface of the gland 2, and the pressure plate 6 is fixed to the outer end of the gland 2 by bolts. Connection, the cone ring 4 is installed in the groove 26 formed between the groove 21 of the gland 2 and the inner surface of the pressure plate 6, the outer diameter ring surface 40 of the cone ring 4 and the groove 26 diameter ring surface 22 of the gland are movable Cooperate, an O-ring seal 66 is provided between the outer diameter ring surface 40 of the cone ring 4 and the groove 26 diameter ring surface 22 of the gland, the axial gap between the cone ring 4 and the groove 26 can be moved and matched, and the pressure plate 6 The inner surface is provided with a spring installation hole 67, and the spring 7 is installed in the spring installation hole 67 on the inner surface of the pressure plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com