A self-lubricating device for a universal joint shaft

A universal joint shaft, self-lubricating technology, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve problems such as the inability to guarantee the amount of refueling and the indeterminacy of the refueling cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

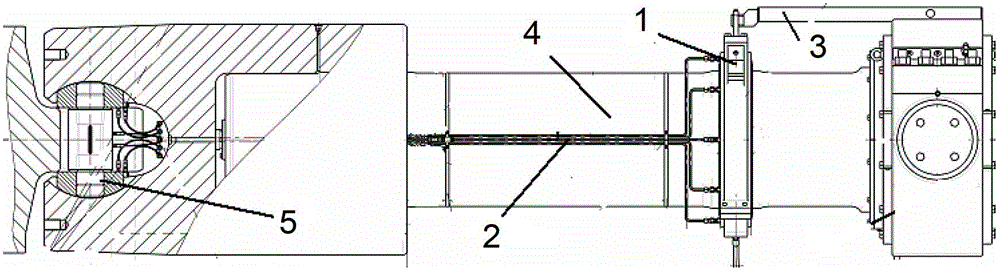

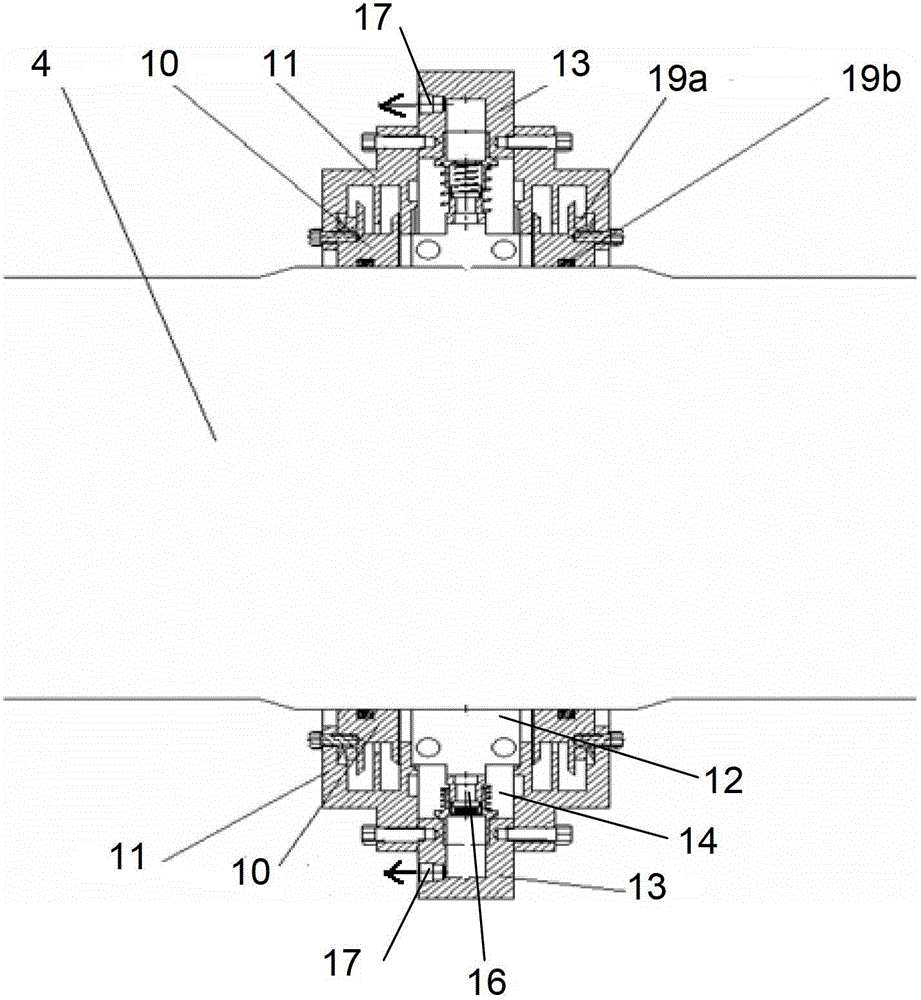

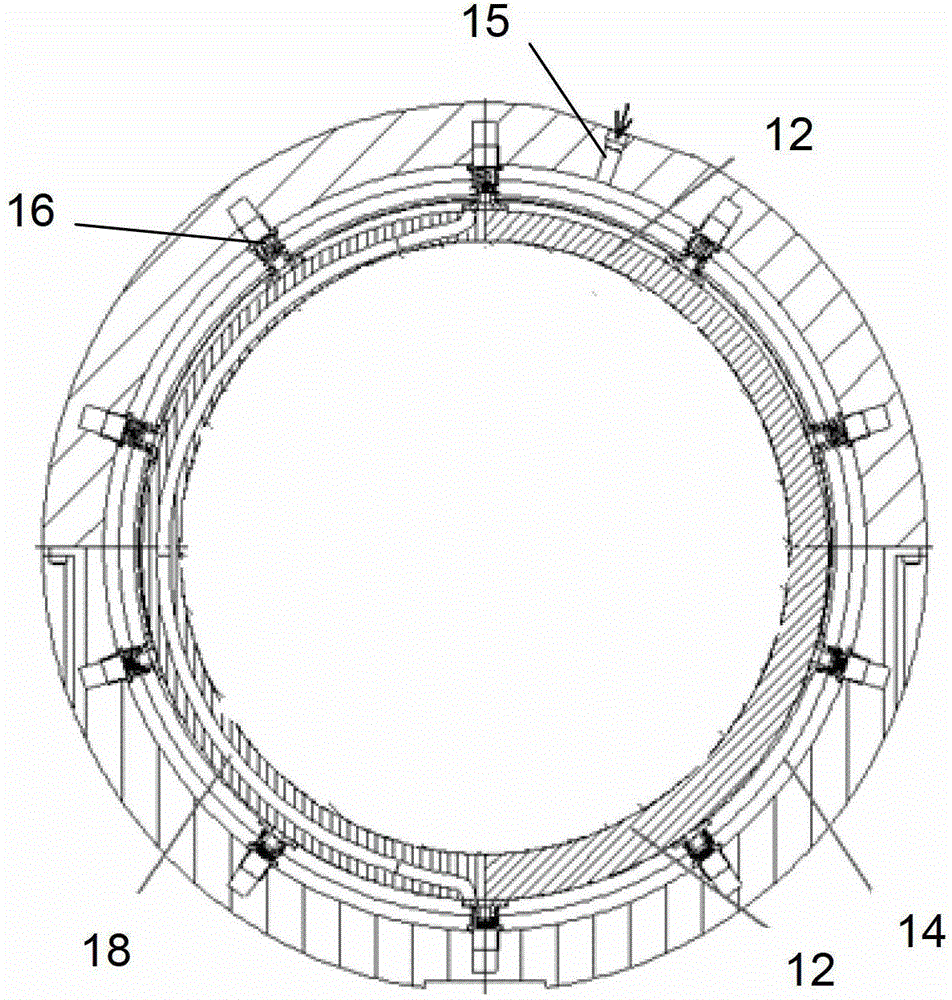

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Please combine Figure 1 ~ Figure 3 As shown, the universal joint shaft self-lubricating device of the present invention mainly includes a self-lubricating body 1 , a lubricating pipeline 2 and a bracket 3 . Among them, the self-lubricating body 1 includes a labyrinth seal ring 10, an end cover 11, an eccentric wheel 12 and a fixed sleeve 13. The eccentric wheel 12 is sleeved on the universal joint shaft 4. After repeated calculations and tests, the eccentric wheel 12 The eccentricity e is designed to be 2 / 5-1 / 2 of the deformation of the return spring 24, the labyrinth seal ring 10 is arranged on both sides of the eccentric wheel 12, the end cover 11 and the labyrinth seal ring 10 are connected by bolts, the fixed sleeve 13 and the The end caps 11 are connected to form an oil storage chamber 14, and the eccentric wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com