A full keycap automatic placement system

A key cap and automatic technology, applied in the direction of vibrating conveyors, conveyors, electrical components, etc., can solve problems such as time-consuming and labor-intensive, difficult machining, and difficult to guarantee quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with specific examples below.

[0034] A full keycap automatic placement system, which includes,

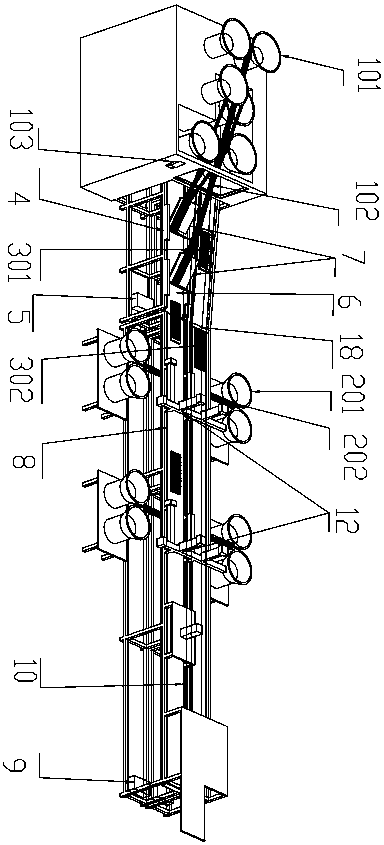

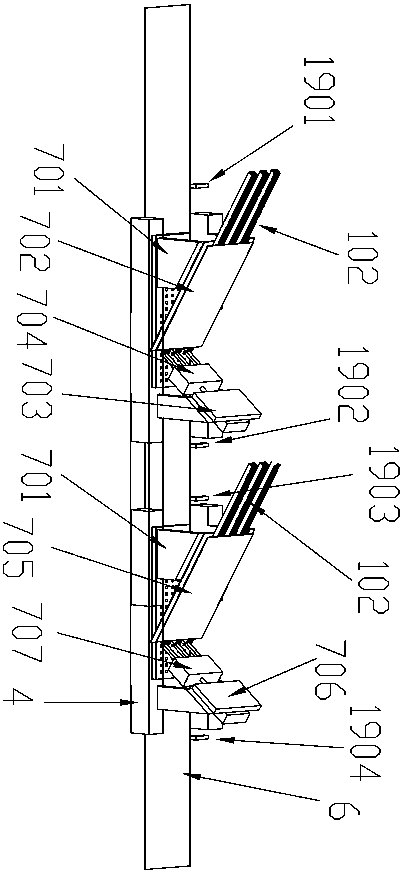

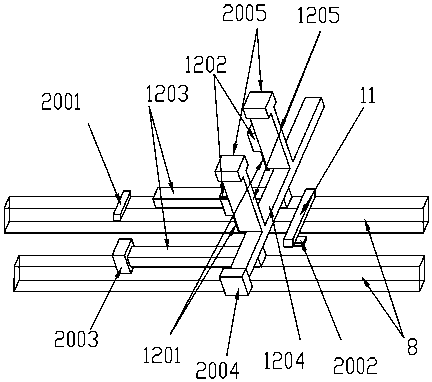

[0035] Feeding device, placement device and control device, feeding device and placement device are matched, respectively divided into standard feeding device and standard placement device, special feeding device and special placement device, standard placement device and special placement device in order Set on the main conveying platform in the main conveying direction, the standard feeding device is equipped with a free sliding track from high to low, and the special feeding device is set on both sides of the main conveying platform, and the keycap template is used as a supporting tool on the main conveying platform.

[0036] The main conveying platform is divided into a conveying belt 6 and a conveying chain belt 10. The conveying belt 6 and the conveying chain belt 10 are adjacent in the same direction and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com