LED (light emitting diode) bulb lamp

A technology of LED bulb lamp and LED light source, which is applied in the direction of lighting and heating equipment, semiconductor devices of light-emitting elements, point light sources, etc., can solve the problems of unfavorable productivity control of defective products, slow welding speed, unreliable welding, etc. To achieve the effect of production convenience and product safety, fast welding speed, and reduce welding wire traps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

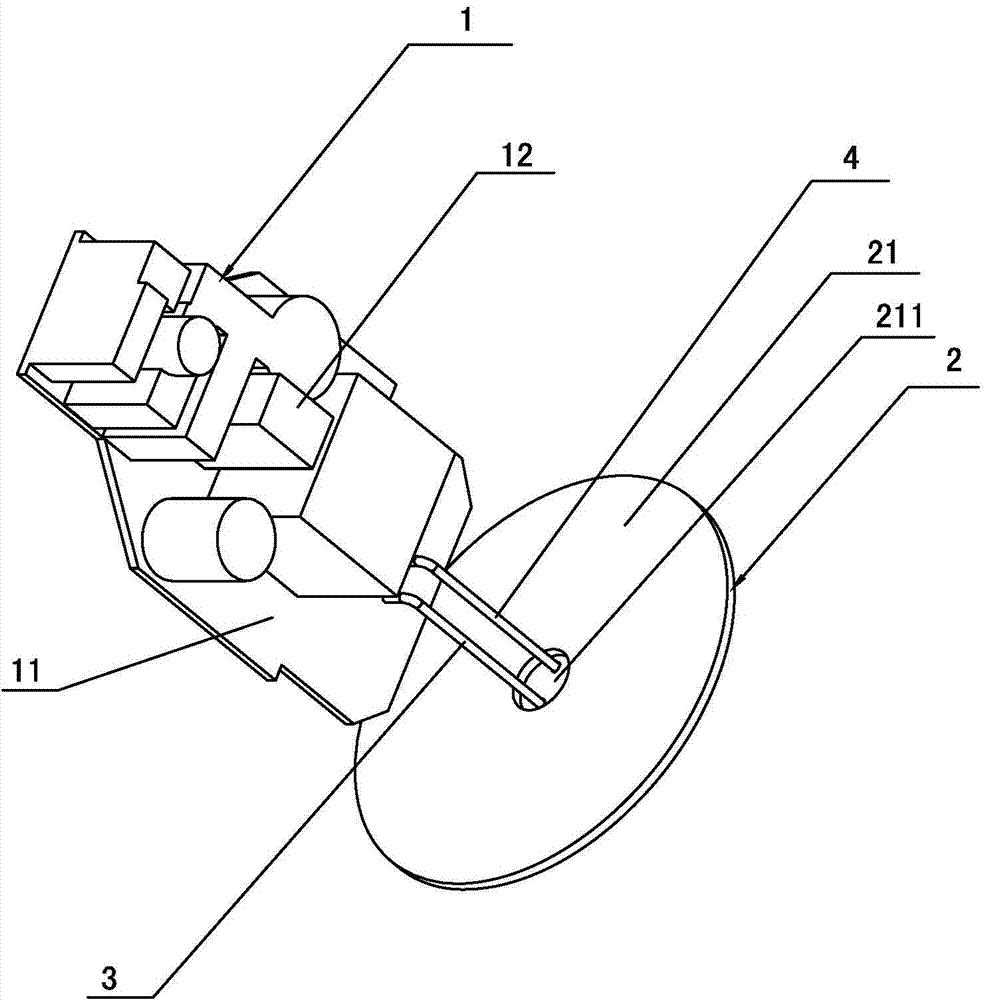

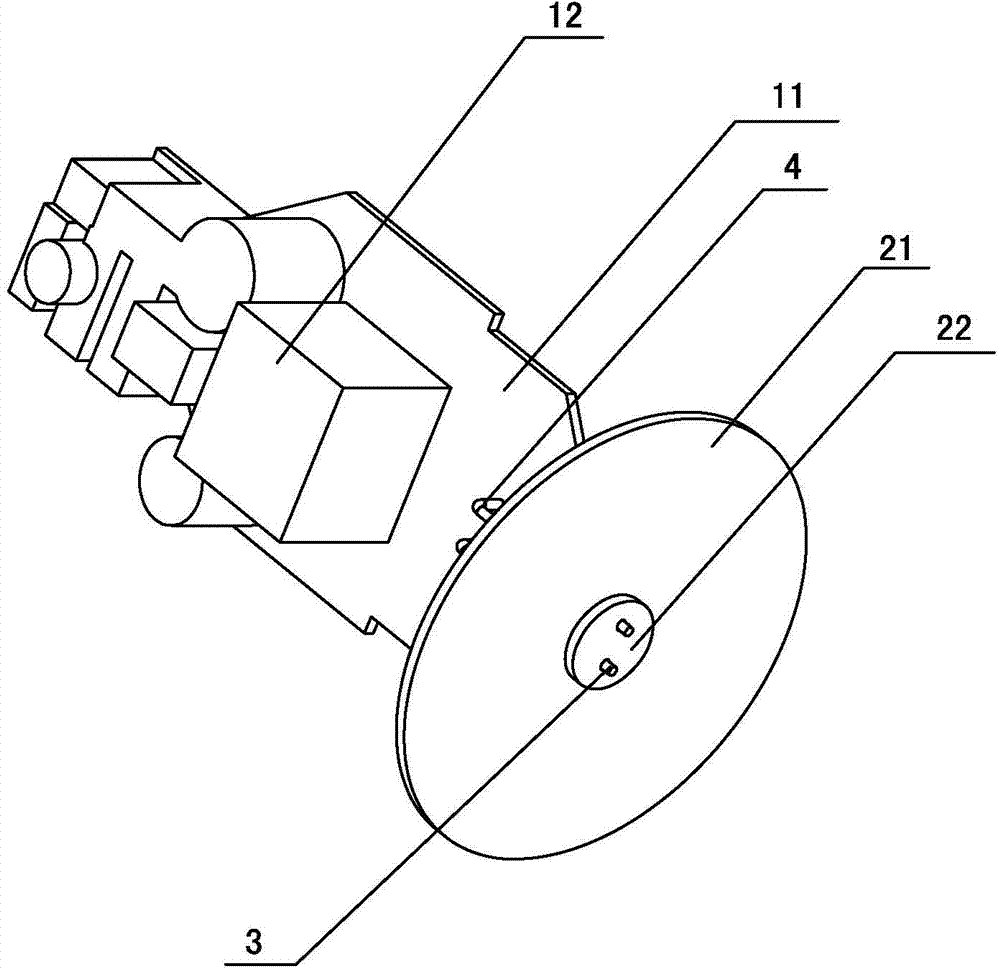

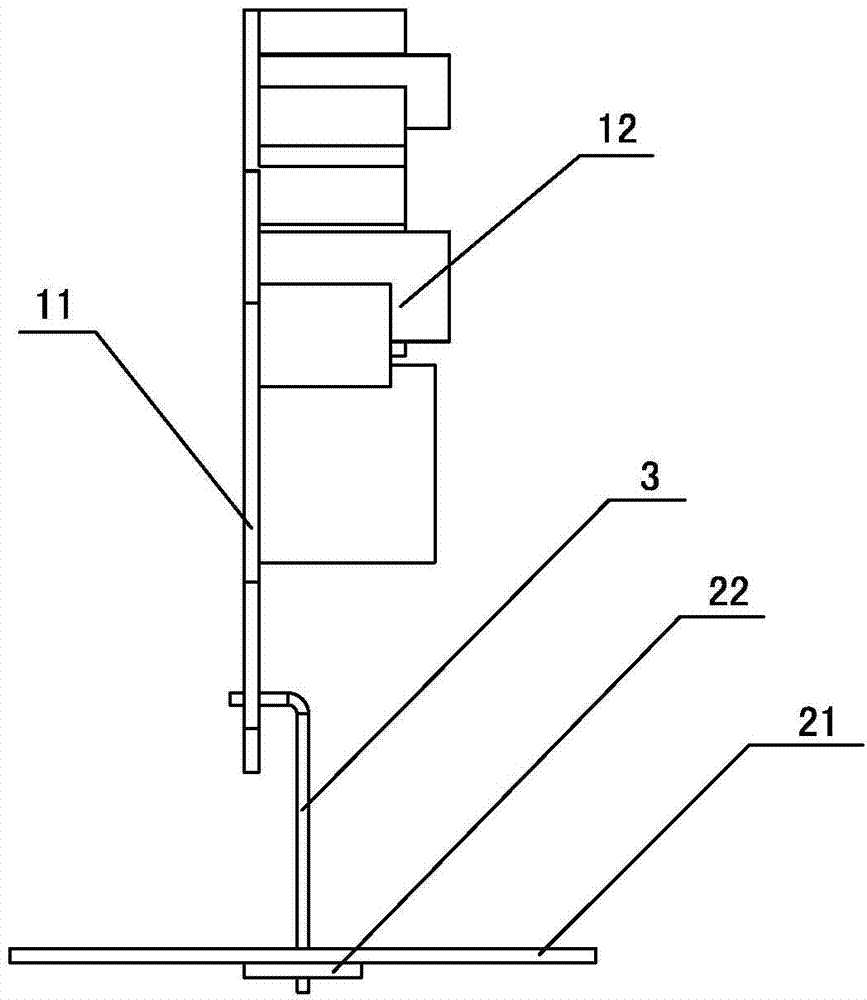

[0018] An LED bulb lamp proposed by the present invention, as shown in the figure, includes a driving power supply assembly 1 and an LED light source assembly 2. The driving power supply assembly 1 is composed of a driving PCB board 11 (FR-4 single-sided PCB board) and connected to The components 12 on the front of the driving PCB 11 are composed. The LED light source assembly 2 is composed of an aluminum substrate 21 and a plurality of LED lamp beads (not shown in the figure) directly attached to the front of the aluminum substrate 21. The driving PCB 11 There are two pin access holes (not shown in the figure), one of which is inserted with an L-shaped first pin 3, and the other pin access hole is inserted with a L-shaped first pin 3. Type of second pin 4, one end of the first pin 3 passes through one of the pin access holes and is welded to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com