Mounting structure and method for flow-equalizing film in purification equipment

A technology of installation structure and purification equipment, applied in the direction of air flow control components, etc., can solve the problems of inconvenient disassembly, restricted production time, and labor costs for installation, and achieves the effects of long production time, improved efficiency, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

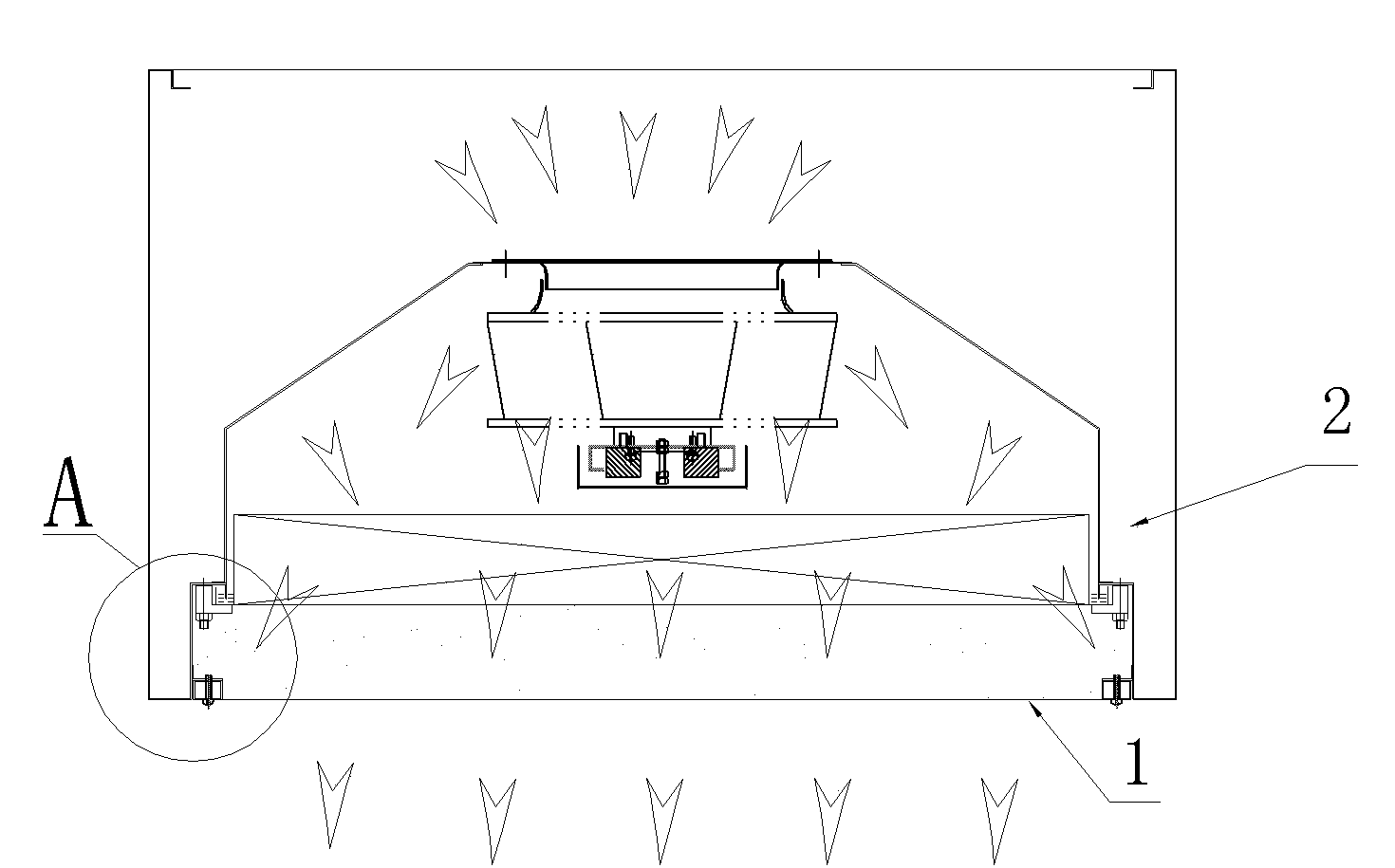

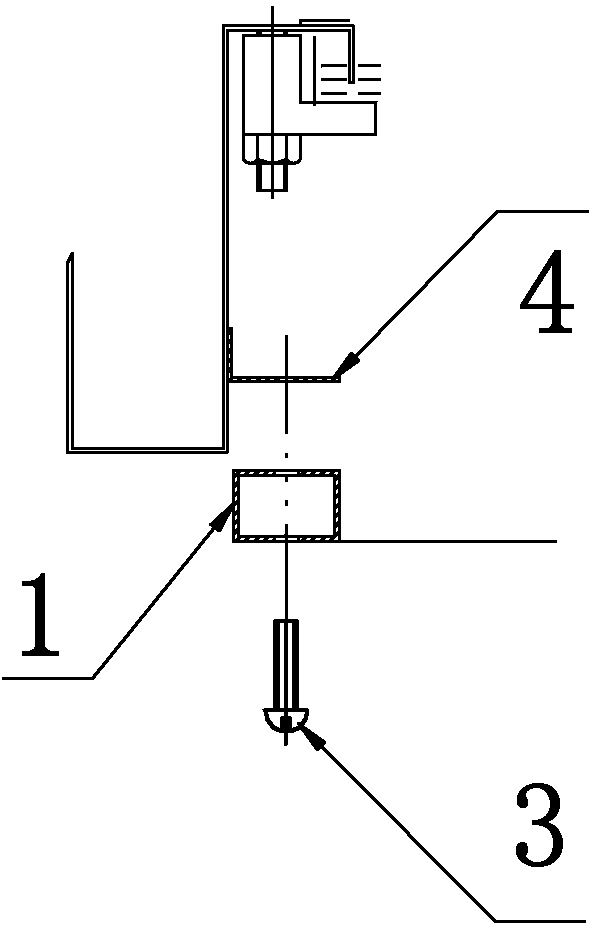

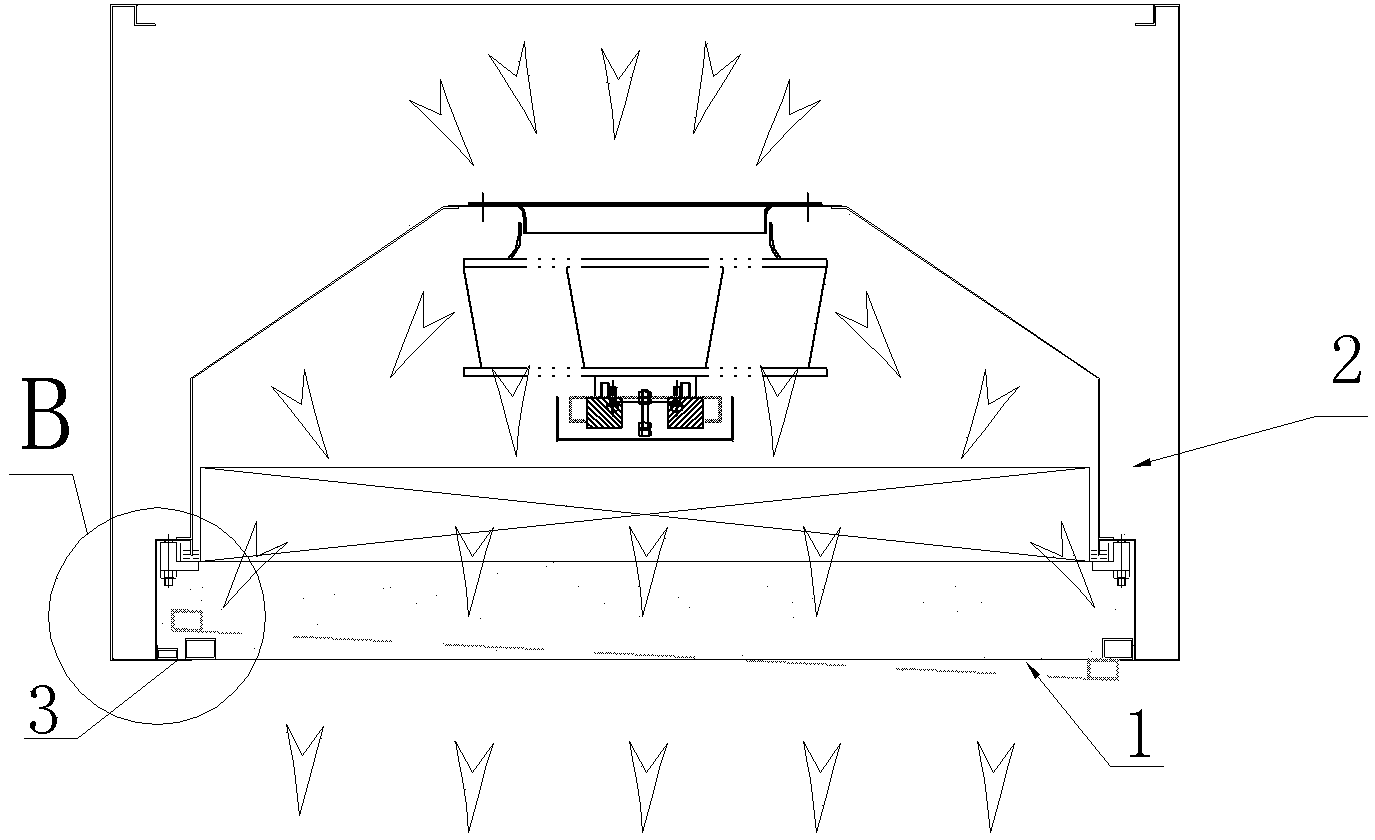

[0014] A kind of installation structure of purification equipment equalizing membrane, see image 3 , Figure 4 : It includes a flow equalizing film 1 and a main box body 2, and an L-shaped support frame 3 is welded on the inside of the bottom of the main box body 2, and the lower end surface of the boundary of the flow equalizing film 1 is supported on the horizontal part 4 of the L-shaped support frame 3 , the limit block 5 is supported on the L-shaped support frame 3, the outer end surface of the outer wall of the limit block 5 is close to the vertical part 6 of the L-shaped support frame 3, and the surrounding of the flow equalizing film 1 The frame is in close contact with the inner wall and outer end surface of the limiting block 5 . The arrows in the figure indicate the direction of wind flow.

[0015] An installation method of a purification equipment flow uniform membrane installation structure,

[0016] A. First fix and weld the L-shaped support frame and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com