Bulb fixing seat

A fixed seat and light bulb technology, which is applied in the manufacture of tube/lamp screen, the manufacture of discharge tube/lamp, electrical components, etc., can solve the problems of human injury, low efficiency, easy splashing of chemical liquid on the human body, etc., and achieve good stability The effect of sex, easy placement and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

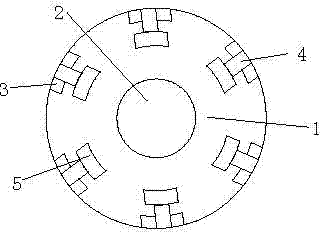

[0012] Combine below figure 1 Specific description embodiment:

[0013] A light bulb fixing seat, comprising a circular bottom plate 1, characterized in that, the center of the circular bottom plate 1 is provided with a circular clamping groove 2, and the circular clamping groove 2 is matched with the bottom of the bulb, so that The side portion of the circular bottom plate 1 is evenly provided with a number of grooves 3, the groove body 3 is provided with an arc-shaped fixing piece 4, and the arc of the arc-shaped fixing piece 4 is in line with the side portion of the circular bottom plate 1. The arc is consistent.

[0014] In a preferred manner, an arc-shaped clip 5 is provided on the inner side of the arc-shaped fixing piece 4 , and the arc of the arc-shaped clip 5 is consistent with the arc of the outer wall of the bulb.

[0015] Preferably, the arc-shaped fixing piece and the arc-shaped clamping piece are elastic pieces.

[0016] In the light bulb fixing seat provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com