A brake device for linear motor

A technology of linear motors and gate devices, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of linear motion speed, acceleration, fast positioning accuracy and difficult breakthrough improvement, and achieve the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

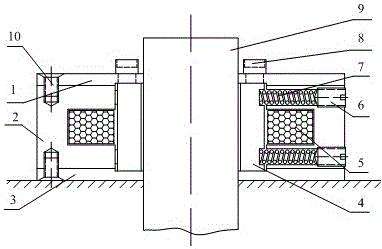

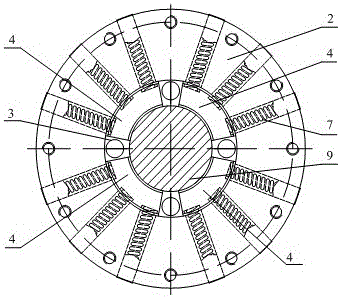

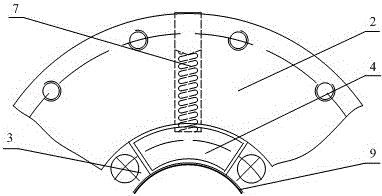

[0019] see figure 1 , The invention discloses a linear motor brake device, the brake device is integrally fixed on the linear motor housing. It includes an upper end cover 1, a static iron core 2, a lower end cover 3, a moving iron core 4, a coil 5, an adjusting nut 6, a return spring 7, bolts 8, a linear motor mover shaft 9, and countersunk screws 10.

[0020] The static iron core 2 is a ring-shaped magnetizer, and the inner ring of the static iron core 2 is embedded with a coil 5; the static iron core 2 is set outside the linear motor mover shaft 9, and the axis of the static iron core 2 coincides with the axis of the linear motor mover shaft 9, and the static iron core 2 There is a gap between the iron core 2 and the rotor shaft 9 of the linear motor.

[0021] The upper and lower surfaces of the static iron core 2 are connected with the upper end cover 1 and the lower end cover 3 through countersunk head screws 10 respectively, and the brake device as a whole is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com