Post-operative rehabilitation exercise device for Stanford A-type aortic dissection patients

A technology of aortic dissection and exercise equipment, which is applied in the direction of passive exercise equipment, sports accessories, gymnastic equipment, etc., can solve the problems of accelerating intestinal peristalsis, increasing lung capacity, and the ability of active exercise is not as good as before the disease, so as to prevent lower limbs from Arterial and venous thrombosis, effect of promoting blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

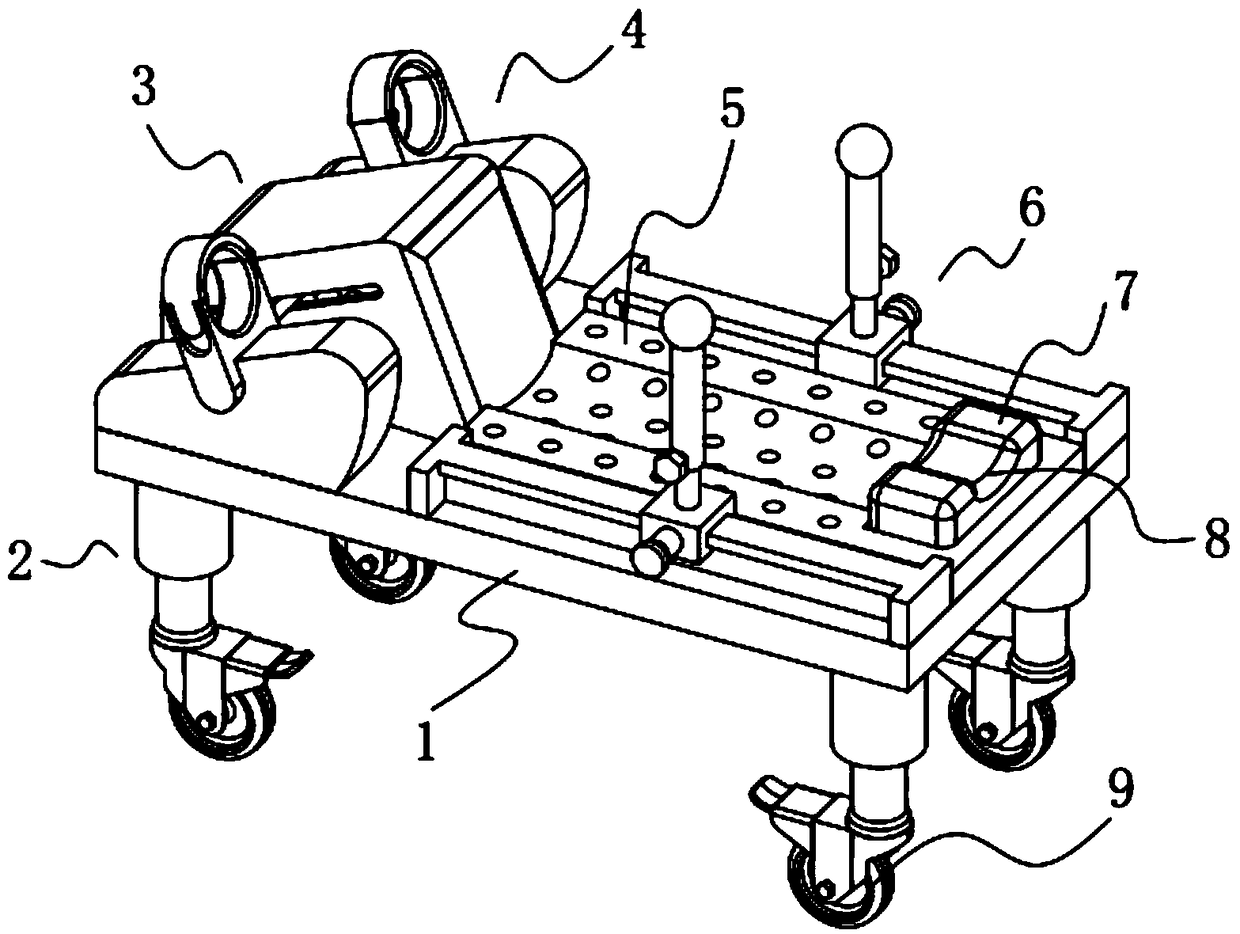

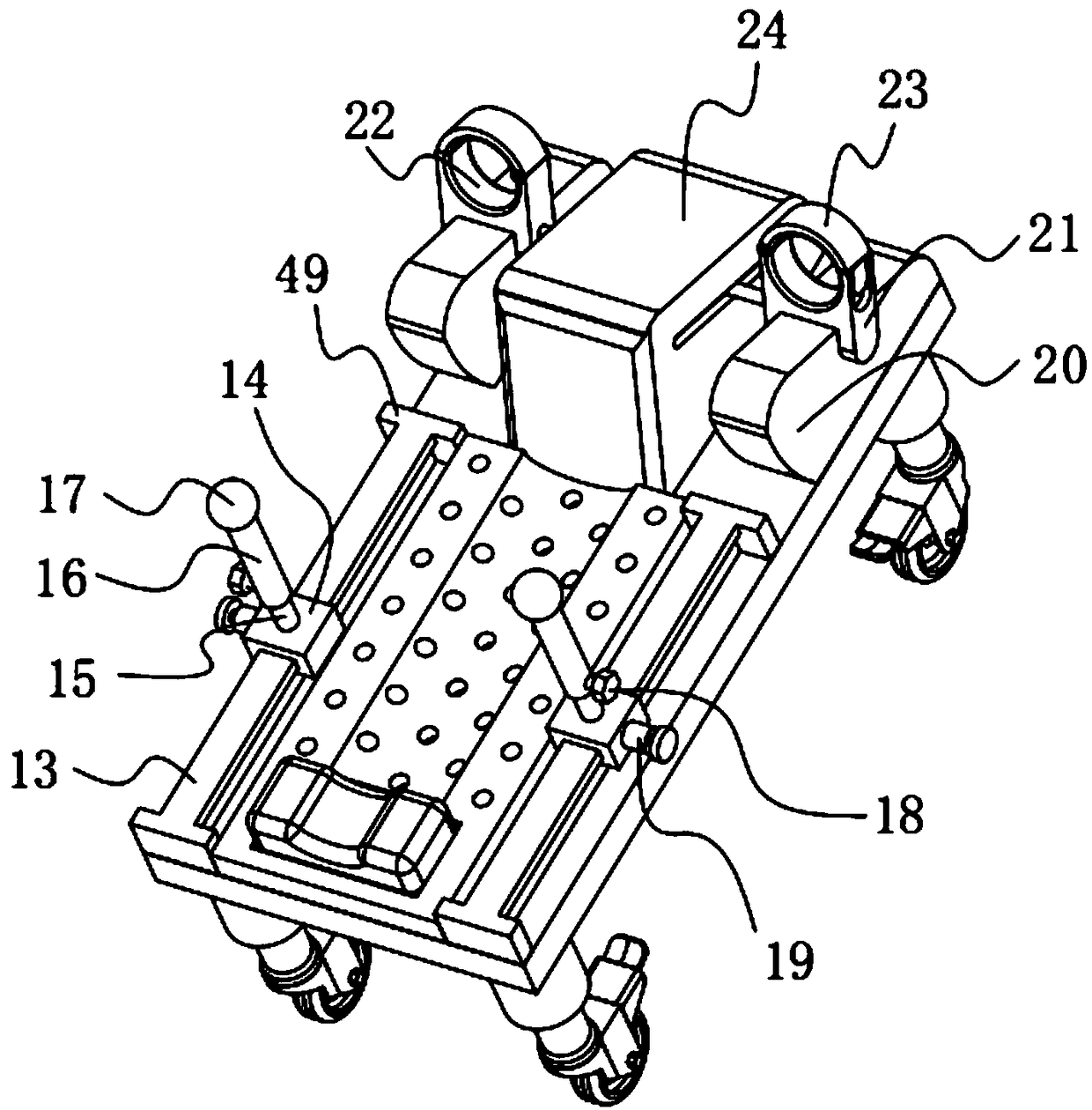

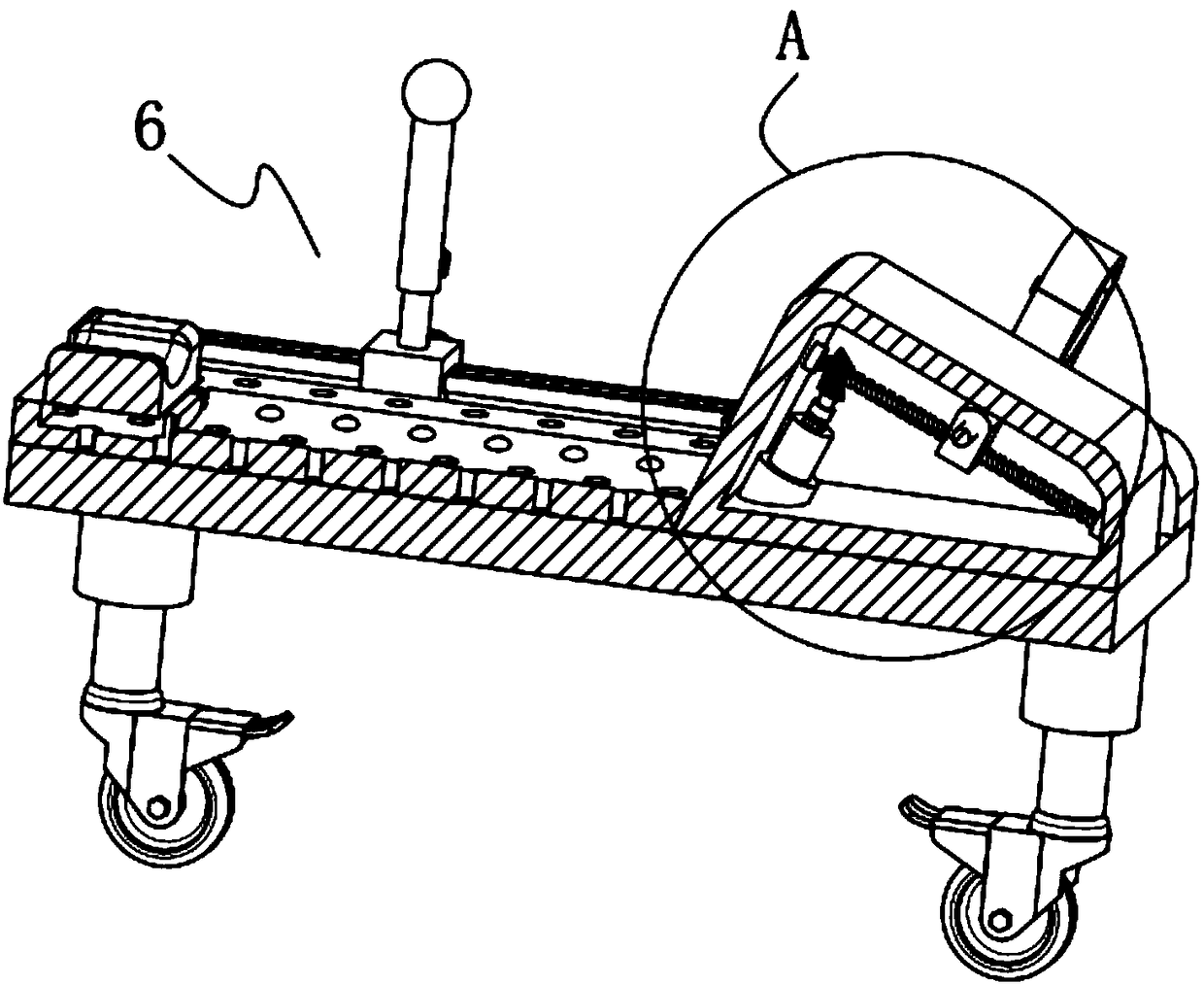

[0061] The following is attached Figure 1-16 The present invention is described in further detail.

[0062] A kind of rehabilitation exercise device for patients with Stanford type A aortic dissection after operation, such as Figure 1-16 As shown, it includes a base plate 1, the upper part of the base plate 1 is centered with a driving device 3 close to one end thereof, and two groups are arranged symmetrically on both sides of the driving device 3 on the upper part of the base plate 1 near one end thereof. Lower limb exercise device 4, the upper part of the base plate 1 is provided with a sponge pad 5 in the center near its other end, and the upper part of the base plate 1 is adjacent to its other end and is located on both sides of the sponge pad 5. Two groups of upper limb exercise devices are arranged symmetrically device 6, the driving device 3 is respectively connected with two groups of lower limb exercise devices 4;

[0063] The driving device 3 includes a housing ...

Embodiment 2

[0076] The difference from Example 1 is that the inner surface of the arc-shaped placement groove 22 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0077] Take the following raw materials and weigh them by weight: 20 parts of phenolic resin, 8 parts of emery particles, 30 parts of water, 5 parts of cellulose acetate, 6 parts of ceramic powder, 9 parts of polyurethane, 2 parts of acrylic leveling agent, high carbon alcohol 3 parts of fatty acid ester compound, 3 parts of polyvinyl alcohol and 3 parts of silane coupling agent;

[0078] S1. Add the weighed phenolic resin, carborundum particles, cellulose acetate, ceramic powder and polyurethane into a ball mill for fine grinding until the particle diameter is 20um to obtain a mixed powder material;

[0079] S2. Add the mixed powder material and water prepared in step S1 into a mixer and stir for 20 minutes, set the temperature to 50°C, and set the stirring speed to 600r / m...

Embodiment 3

[0085] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0086] Take the following raw materials and weigh them by weight: 25 parts of phenolic resin, 10 parts of emery particles, 40 parts of water, 8 parts of cellulose acetate, 8 parts of ceramic powder, 11 parts of polyurethane, 3 parts of acrylic leveling agent, high carbon alcohol 4 parts of fatty acid ester compound, 4 parts of polyvinyl alcohol and 5 parts of silane coupling agent;

[0087] S1. Add the weighed phenolic resin, carborundum particles, cellulose acetate, ceramic powder and polyurethane into a ball mill for fine grinding until the particle diameter is 30um to obtain a mixed powder material;

[0088] S2. Add the mixed powder material and water prepared in step S1 into the mixer and stir for 25 minutes, set the temperature to 65°C, and set the stirring speed to 700r / min;

[0089] S3. After the mixer in step S2 stops working, add acryli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com