Explosion-proof housing of battery

An explosion-proof shell and battery technology, which is applied in the direction of battery box/coat, battery cover/end cover, battery pack parts, etc., can solve the problem of easy leakage of explosion-proof cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

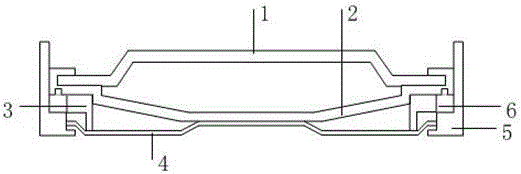

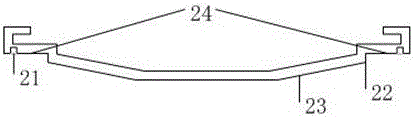

[0011] Such as figure 1 , figure 2 As shown, the structure of the present invention includes: a combined battery explosion-proof cover and an explosion-proof steel shell 31, the combined battery explosion-proof cover is stamped and fixed on the explosion-proof steel shell 3, and its opening pressure is tested to be 1.9-2.5Mpa, which conforms to Industry requirements; the assembled battery explosion-proof cover includes a sealing ring 5, a top cover 1, an explosion-proof disk 2, an insulating ring 3, and an orifice plate 4; the top cover 1 is a round iron sheet with a raised structure in the middle, so There are 3 air holes evenly distributed on the side of the convex structure; the explosion-proof disc 2 is a circular aluminum sheet, and the middle of one side has a cylindrical protrusion 22, and the cylindrical protrusion 22 has a tapered protrusion 23. , There is an annular groove 21 between the outer ring of the cylindrical protrusion 22 and the outer ring 24 of the explosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com