Diaphragm pump and method for delivering fine-grain powder with the aid of a diaphragm pump

一种膜片泵、粉末的技术,应用在膜片泵和用于借助于膜片泵输送细粒粉末领域,能够解决膜片泵堵塞、降低抽吸功率、阻塞膜片泵等问题,达到有效清洁的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

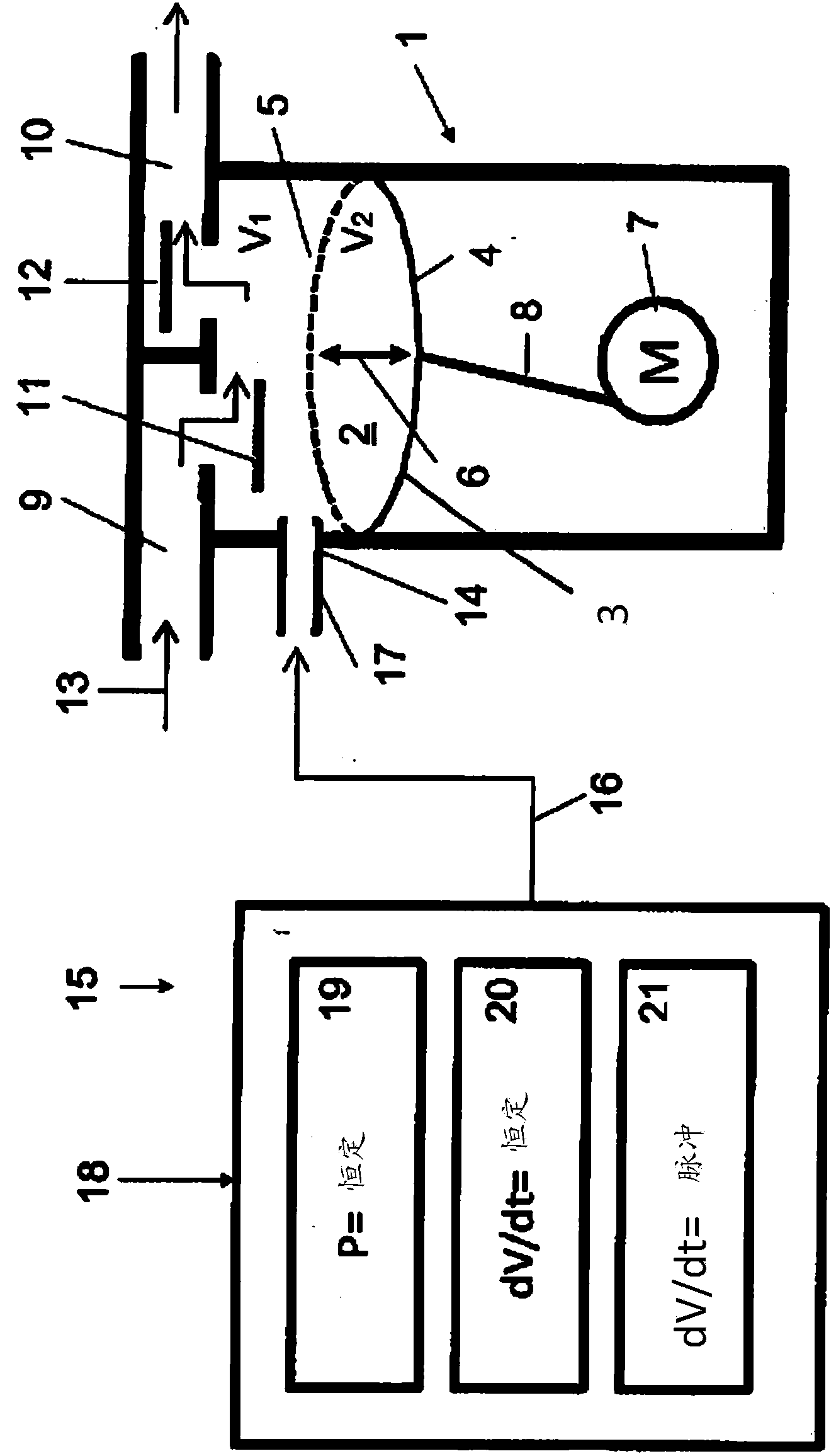

[0023] Diaphragm pump 1 includes surrounding working volume V 1 Or V 2 The delivery cavity 2 is defined on one side by a deflectable diaphragm 3. The diaphragm 3 can be brought into the suction position 4 and the pressure position 5. in figure 1 The middle diaphragm 3 is in the suction position 4 shown by a solid line. The oscillating offset movement 6 is produced by means of an eccentric drive device, which includes a motor 7 and a connecting rod 8.

[0024] An inlet valve 11 is provided on the suction side 9 of the diaphragm pump 1 and an outlet valve 12 is provided on the pressure side of the diaphragm pump 1. Both the inlet valve 11 and the outlet valve 12 are operated under pressure control by the powder / gas mixture delivered by the diaphragm pump 1, wherein the inlet valve 11 opens during the suction stroke of the diaphragm 3 into the suction position 4 and enters the pressure position 5 is closed during the pressure stroke, while the outlet valve 12 is closed during the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap