An impact mechanism, rock drill and drill rig comprising such impact mechanism

A technology of impact mechanism and stroke, used in impact drilling, reciprocating drilling rigs, portable impact tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

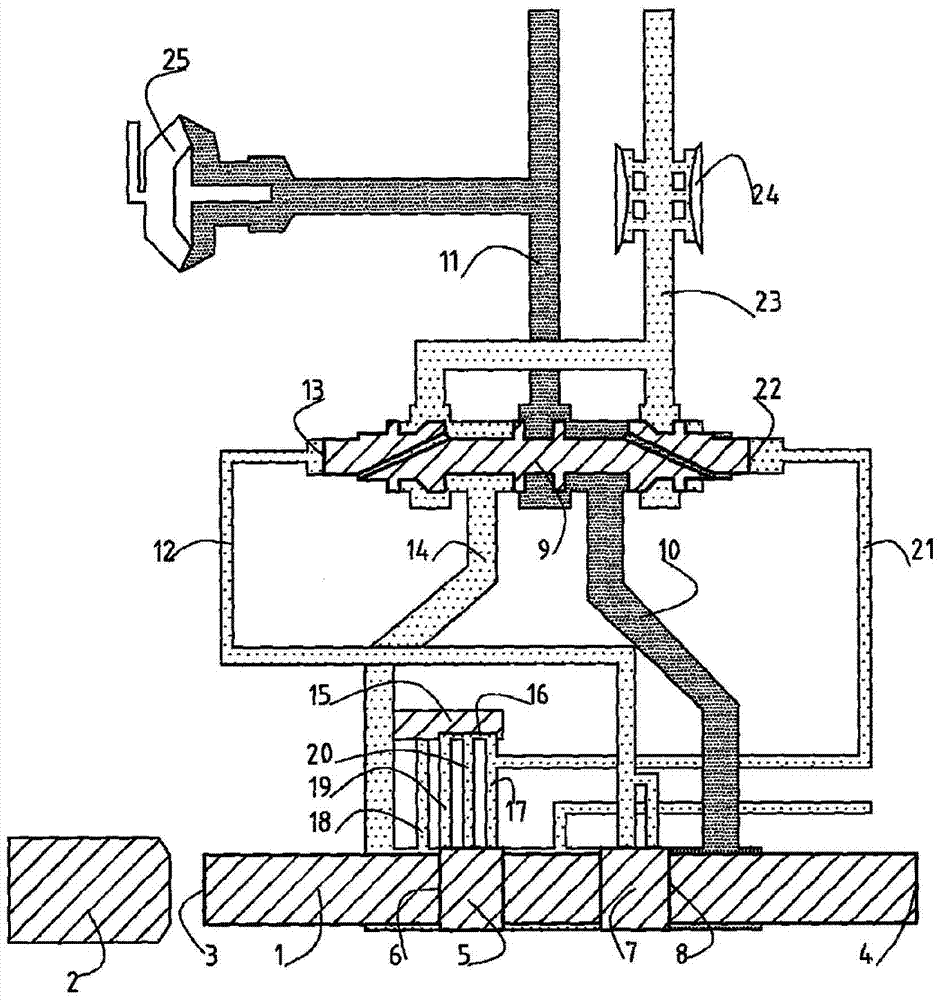

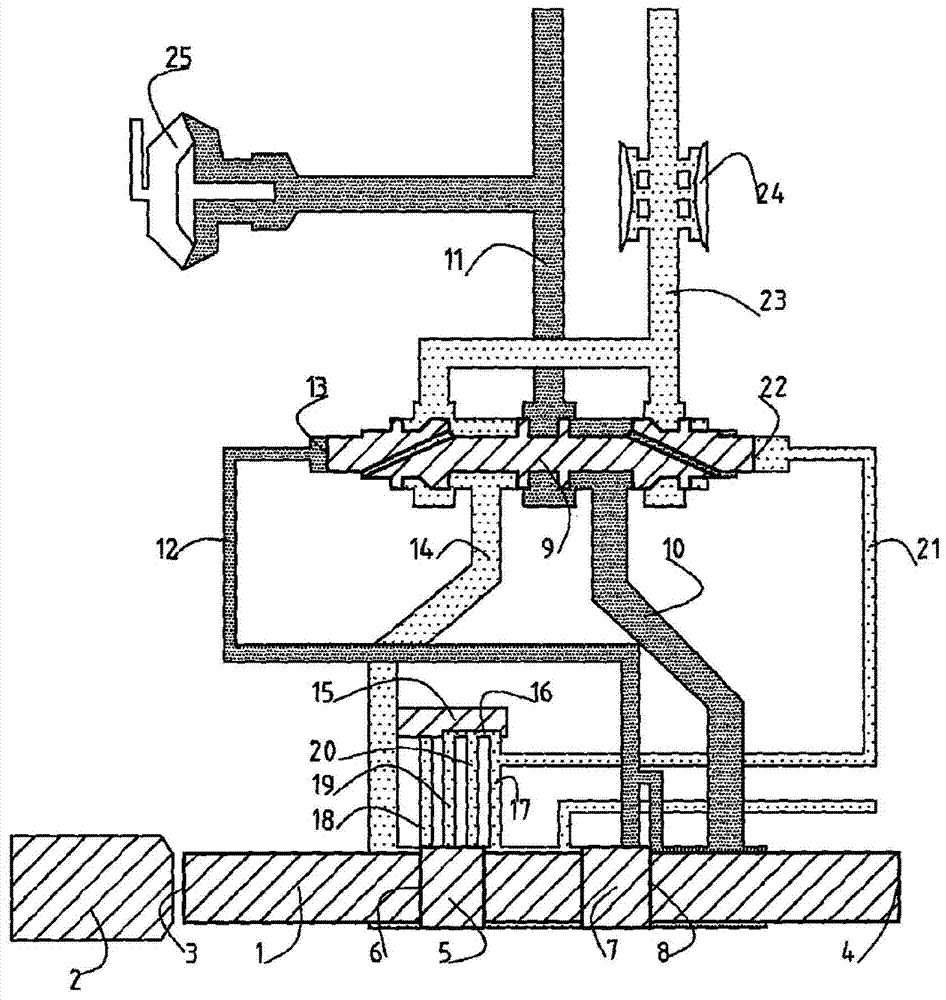

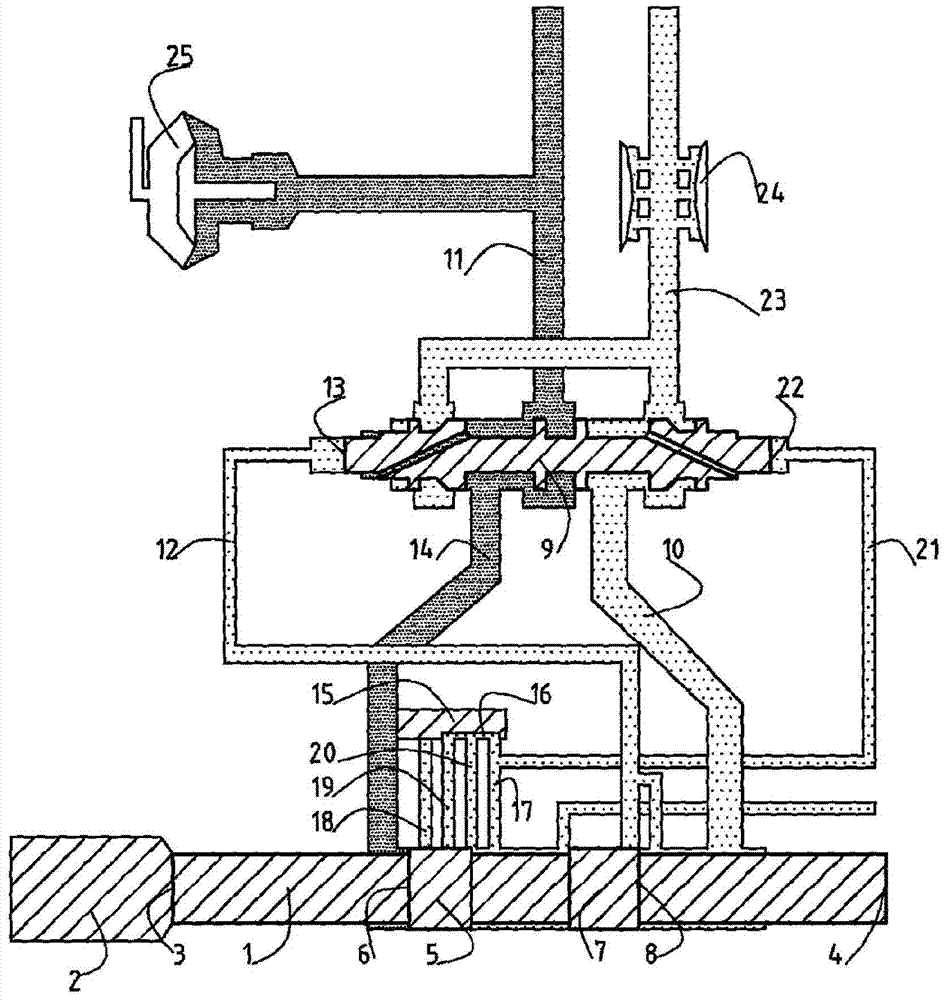

[0015] Figure 1a to Figure 1d It schematically shows a hydraulic down-the-hole hammer drill arranged in a housing in the prior art, and the hammer drill has an alternating pressure type hammer mechanism. The impact mechanism comprises a pneumatic hammer piston 1 which moves forward and backward and impacts on a shank adapter 2 or the like. The shank adapter 2 then transfers the impact energy to the rock through the drill string (not shown in the figures) and the drill bit (not shown in the figures).

[0016] The front end 3 of the jackhammer piston is here the end of the impact shank adapter 2 , while the rear end 4 of the jackhammer piston is the end oriented away from the shank adapter 2 . The pneumatic hammer piston 1 in this example comprises a front piston boom 5 with a front drive area 6 and a rear piston boom 7 with a rear drive area 8 . Forward and backward movement is controlled by means of a valve piston 9 and several channels. The inclusion of accumulator 25 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com