Apparatus for cutting of plastically deformable strand material

A technology of cutting device and deforming material, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of increasing the load of the guide surface, difficulty in guiding the clamping frame, reducing the working life and other problems, reducing the structure size, improving the guiding or Driving conditions, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

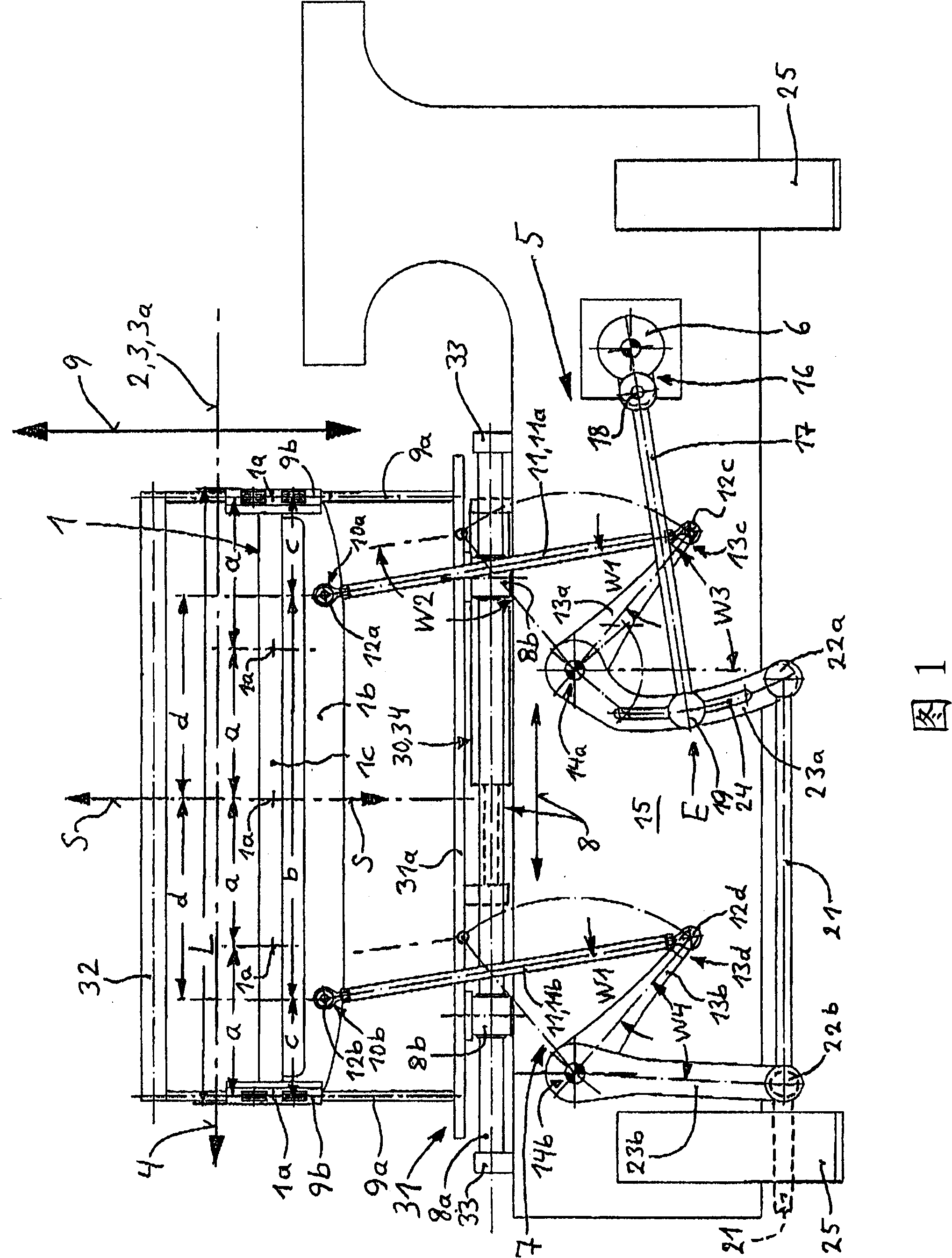

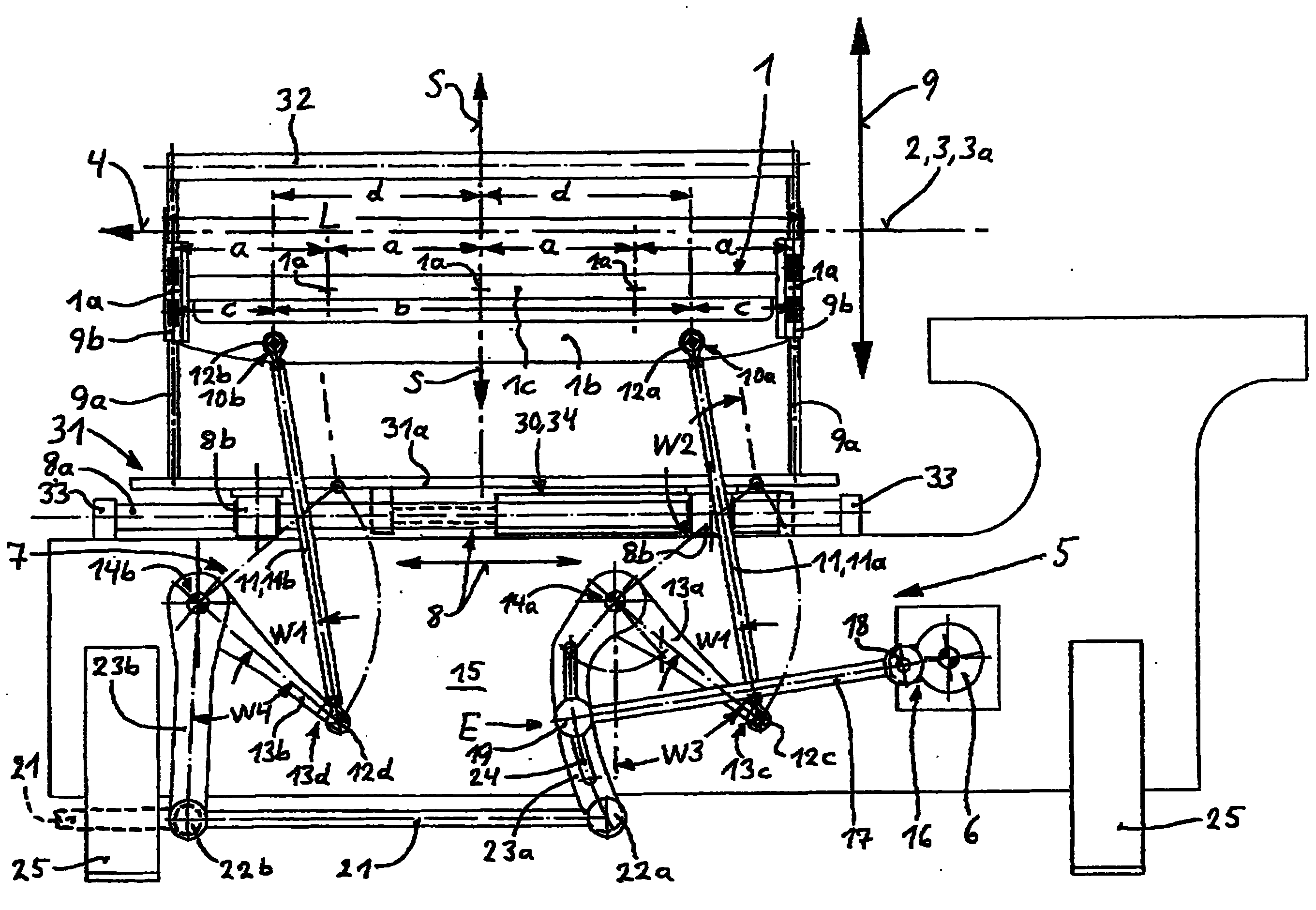

[0017] The essential part of the device shown in simplified form is the holding frame 1 , which is used to hold at least one cutting line 1 a , shown in simplified form as a point of intersection, which is secured end-to-side in a manner not shown. The clamping frame 1 and the cutting line 1a are arranged so that the clamping frame 1 and the cutting line 1a are displaced laterally with respect to the strip 3 represented only by the longitudinal center axis 2 or with respect to the channel 3a for the strip 3, so that the clamping frame 1 and the cutting line 1a are in the The channel 3a is formed at a position shown laterally offset with respect to the initial position of the channel 3a. Here, the clamping frame 1 and the cutting line 1a are arranged below (see the drawing) or above the channel 3a or laterally offset relative to the channel 3a. As a result, the cutting movement of the clamping frame 1 as well as the transverse drive movement and corresponding transverse guidanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com