Synthetic resin bottle

A technology of synthetic resin and bottle body, which is applied in the field of small fine-mouth bottle body and its forming, which can solve the problems of reducing the diameter of the core mold, the wall thickness of the part that cannot be bulged is sufficient, and the contents are accidentally ejected to the outside, etc., to achieve the realization of The effect of weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

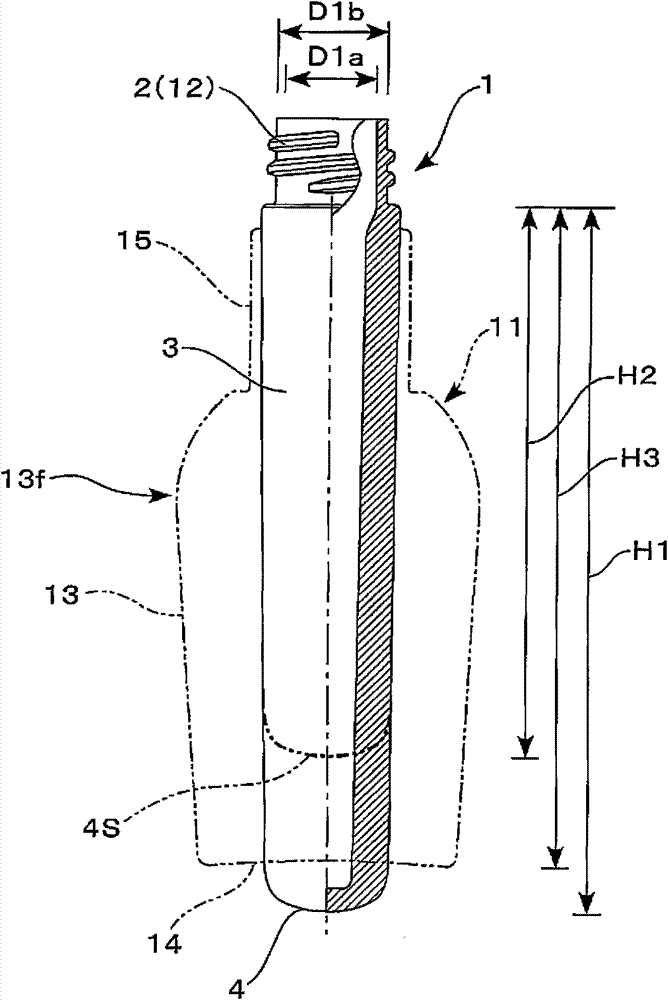

[0092] Hereinafter, embodiments of the present invention will be described based on examples with reference to the drawings. figure 1 It is a figure for explaining an example of the forming method of the biaxial stretching blow molding of the present invention, and in order to easily judge the dimensional relationship, figure 1 Among them, the preform 1 (partial longitudinal section front view) and the bottle body 11 (front view indicated by a two-dot chain line) formed by injection molding are combined with their respective mouthpiece parts 2 and mouthpiece parts 12 The state of the positional overlay is overlaid.

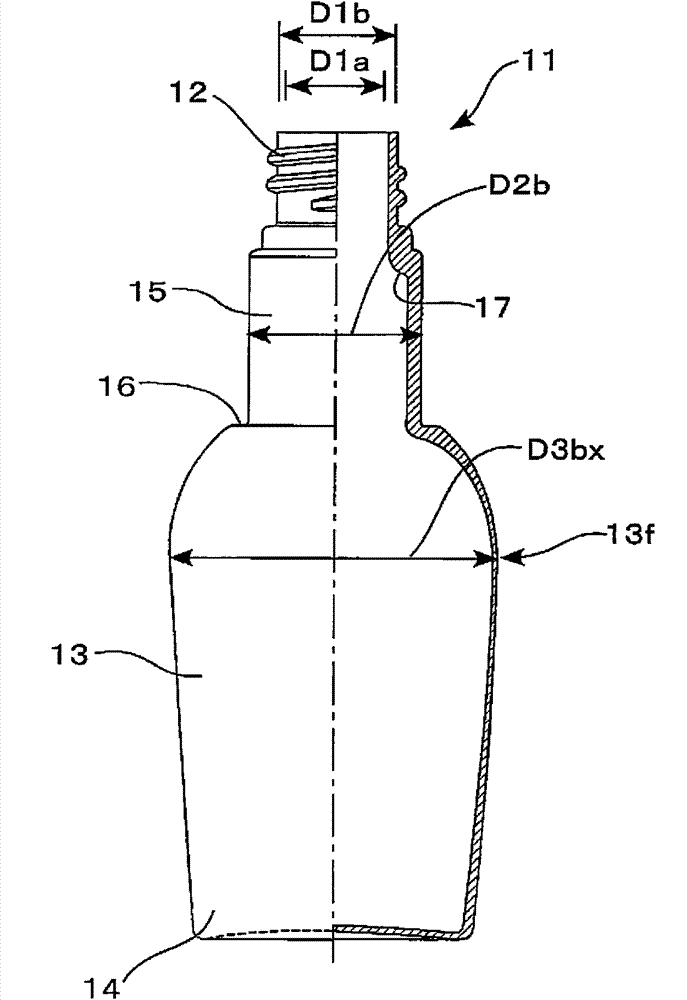

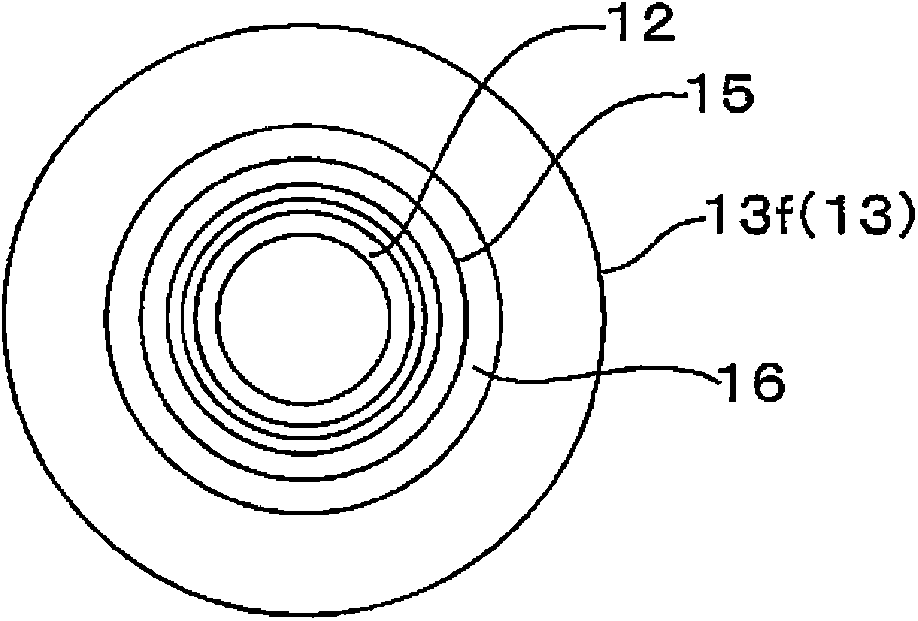

[0093] in addition, figure 2 , image 3 are represented by figure 1 A semi-longitudinal front view and a plan view of an example of the synthetic resin bottle body of the present invention formed by the molding method shown.

[0094] in addition, Figure 4 It is a half longitudinal sectional front view showing an example of a mascara makeup material containe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap