Low voltage fuse disconnect switch

A technology of isolating switches and fuses, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of load equipment damage, easy installation, looseness, etc., and achieve the effect of ensuring normal use and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

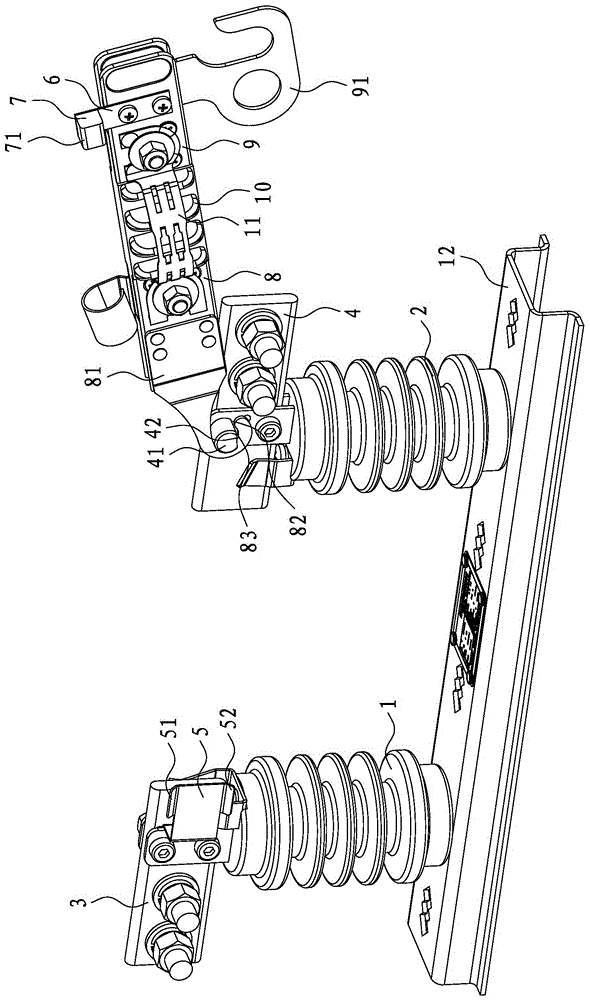

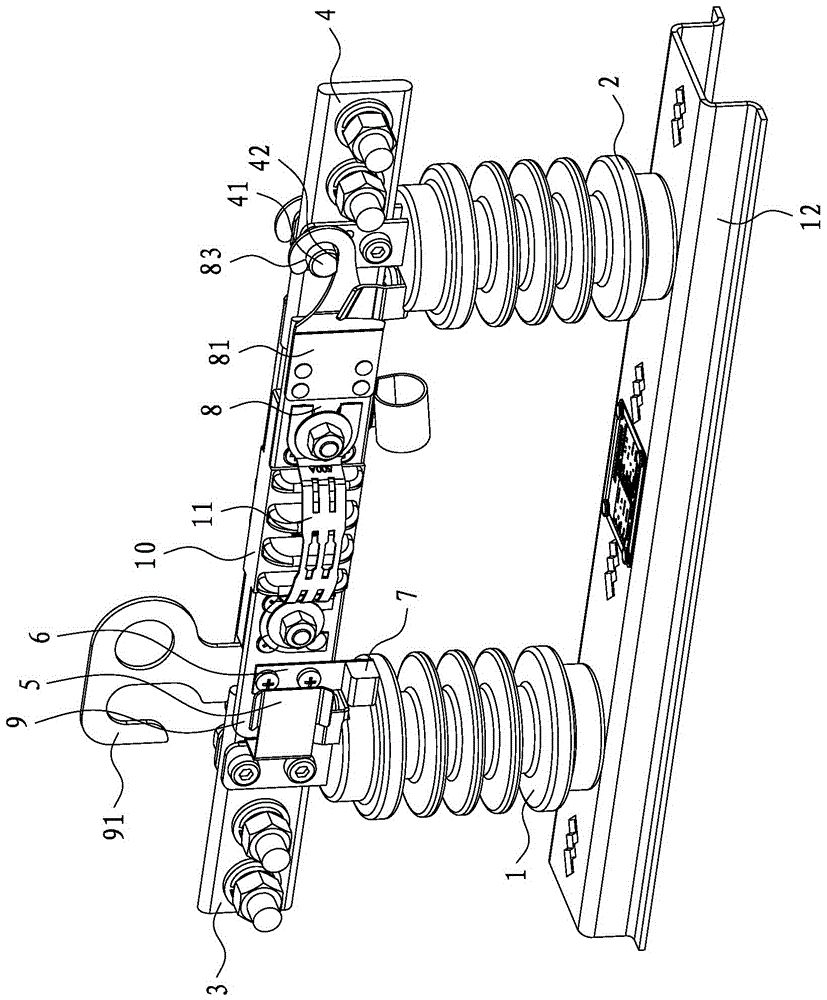

[0022] Such as figure 1 and figure 2 As shown, the low-voltage fuse-type isolating switch disclosed by the present invention includes an insulating post moving end 1, an insulating post static end 2, a moving contact plate 3, a static contact plate 4, a static arc striking plate 5, a moving arc striking plate 6, an extinguishing Arc carbon brush 7, static contact knife 8, moving contact knife 9, insulating pull rod 10 and fuse 11.

[0023] The bottom of the moving end 1 of the insulating support and the static end 2 of the insulating support are installed on the base 12, the moving contact plate 3 and the static contact plate 4 are respectively installed on the moving end 1 of the insulating support and the static end 2 of the insulating support, and one end of the static contact knife 8 pivots Connected to the static contact plate 4, the other end of the static contact knife 8 is connected to one end of the movable contact knife 9 through an insulating pull rod 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com