Insulation heat pipe radiator of explosive-proof structure

A heat pipe radiator and explosion-proof technology, which is applied in the direction of electric solid devices, semiconductor devices, cooling/ventilation/heating transformation, etc., can solve the restrictions, limit the promotion of medium and high voltage electric transmission devices, and cannot meet the insulation requirements of medium and high voltage electric transmission devices and other problems, to achieve the effect of insulation and flameproof, to meet the heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

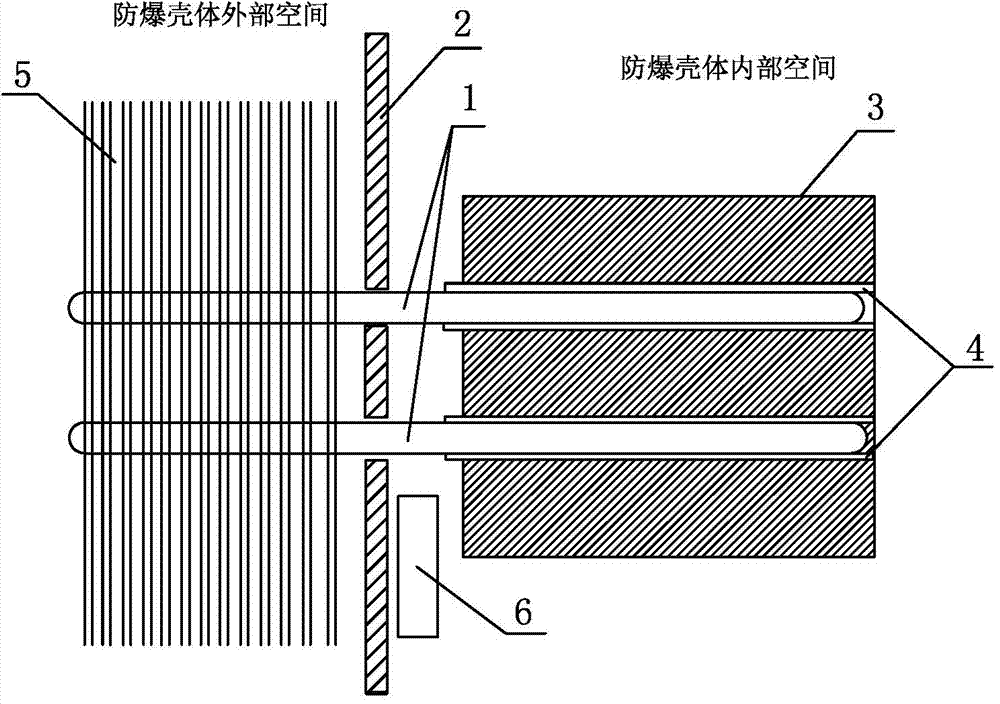

[0024] like figure 1 As shown, the flameproof structure insulated heat pipe radiator of this embodiment includes: a flameproof shell 2, which divides the space into an inner space of the flameproof shell and an outer space of the flameproof shell; The internal space of the body is provided with an internal heat pipe insulation and heat dissipation device. The internal heat pipe insulation heat dissipation device includes a thermally conductive substrate 3, and a substrate hole is arranged inside the thermally conductive substrate 3, and the extension direction of the substrate hole is consistent with the extension direction of the thermally conductive substrate; the internal heat pipe 1 , the internal heat pipe 1 has a heat receiving end and a heat dissipation end, wherein the heat receiving end of the internal heat pipe 1 is penetrated in the substrate hole, and a thermally conductive insulating material 4 is arranged between the hole wall of the substrate hole and the heated ...

Embodiment 2

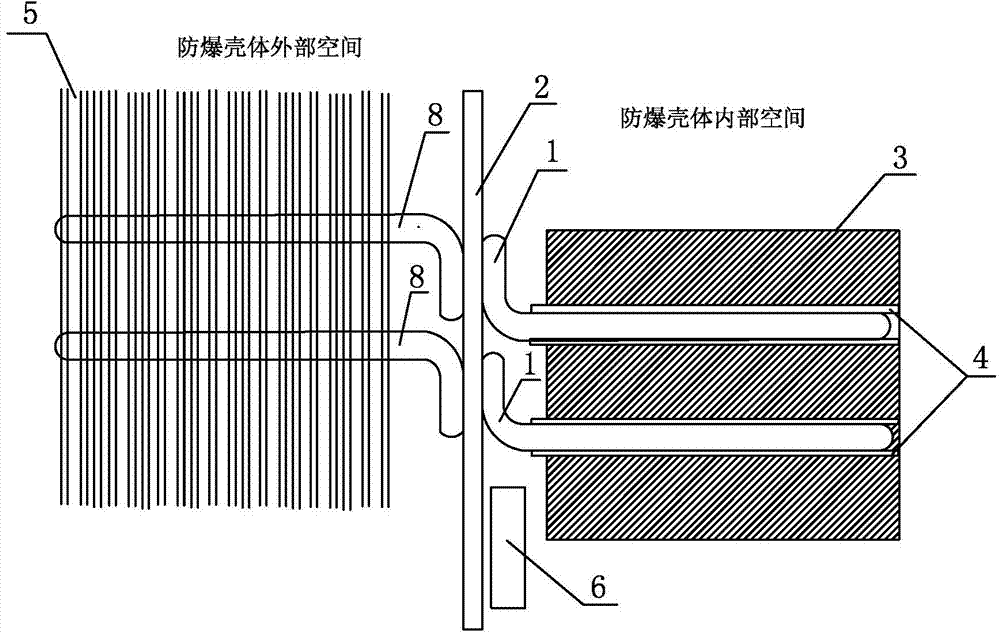

[0029] like figure 2 As shown, the second embodiment is basically the same as the first embodiment, the difference is that the inner heat pipe 1 and the outer heat pipe 8 are arranged in a split type, and both are in a horizontal "L" shape. The heat dissipation end of the inner heat pipe 1 is fixed on the inner wall of the flameproof casing 2 , and the heat receiving end of the outer heat pipe 8 is fixed on the outer wall of the flameproof casing 2 .

[0030] The heat dissipation process of the flameproof structure insulating heat pipe radiator in this embodiment: the power semiconductor device is attached to the thermally conductive substrate 3, and the heat generated by the power semiconductor device is transferred to the heated end of the internal heat pipe 1 through the thermally conductive substrate 3 and the thermally conductive insulating material 4. The vapor and liquid phase change of the medium in the heat pipe 1 transfers the heat to the heat dissipation end of the...

Embodiment 3

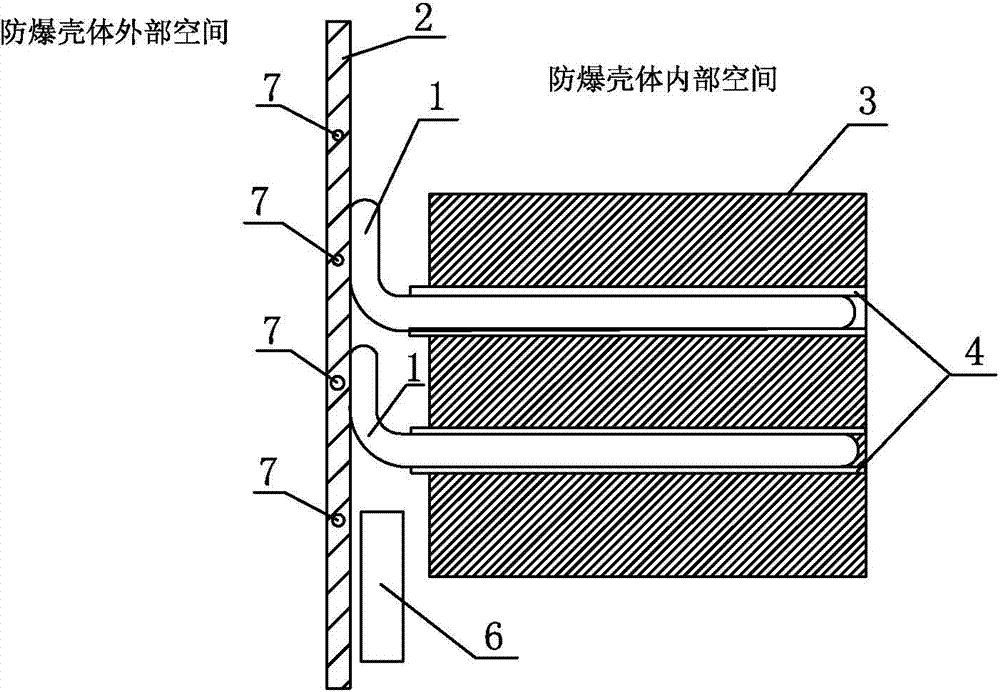

[0032] like image 3 As shown, the difference between Embodiment 3 and Embodiment 1 and Embodiment 2 is that the flameproof structure insulating heat pipe radiator of Embodiment 3 does not have an external heat pipe radiator in the outer space of the flameproof casing, but this embodiment For example, a flameproof shell heat dissipation device is provided on the shell wall of the flameproof shell 2, that is, a fluid heat dissipation channel 7 is provided on the shell wall of the flameproof shell 2, and a heat dissipation fluid circulates in the fluid heat dissipation channel 7.

[0033] The heat dissipation process of the flameproof structure insulating heat pipe radiator in this embodiment: the power semiconductor device is attached to the thermally conductive substrate 3, and the heat generated by the power semiconductor device is transferred to the heated end of the internal heat pipe 1 through the thermally conductive substrate 3 and the thermally conductive insulating mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com