A self-circulating cooling system for heat dissipation of LED lamps

A technology of LED lamps and cooling systems, applied in the cooling/heating devices of lighting devices, refrigerators, refrigeration and liquefaction, etc., can solve the problems of affecting the service life of products, low heat dissipation efficiency, poor heat dissipation effect, etc., and prolong the service life. , The effect of high heat dissipation efficiency and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

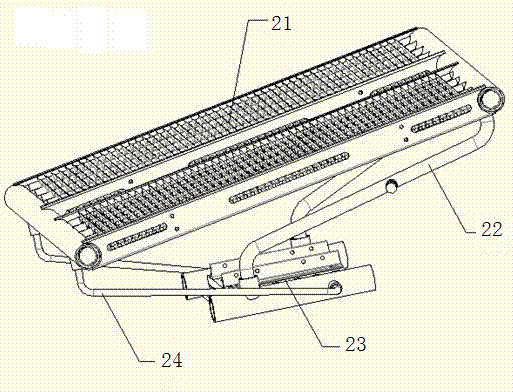

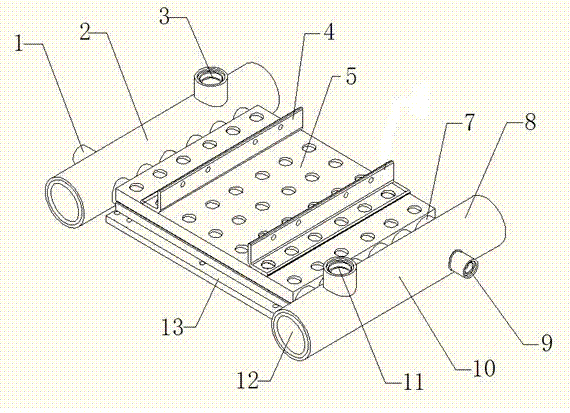

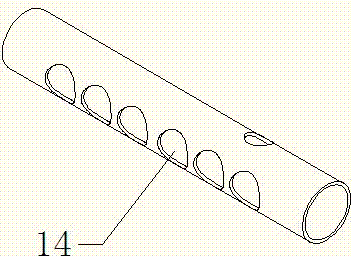

[0021] From figure 1 Shown the structural representation of the present invention and figure 2 It can be seen from the schematic diagram of the evaporator structure that the present invention is composed of an evaporator 23, a condenser 21, a pipeline I22, and a pipeline II24. The evaporator includes a left header 2, a right header 8, a cooling pipe 7, and an upper cover 5. The lower cover plate 13, the support frame 4, the connecting pipe, etc., the heat dissipation pipe 7 is clamped between the upper cover plate 5 and the lower cover plate 13, the upper cover plate 5 is installed above the heat dissipation pipe 7, and the lower cover is installed below plate 13. Heat dissipation pipe 7, left header 2, right header 8, upper cover plate 5, lower cover plate 13, support frame 4, and connecting pipes are assembled together in a certain order, fixed with special tooling, and vacuum brazed once welded. The evaporator 23 and the condenser 21 are connected to form a cooling syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com