Intermediate lever

A lever, variable technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

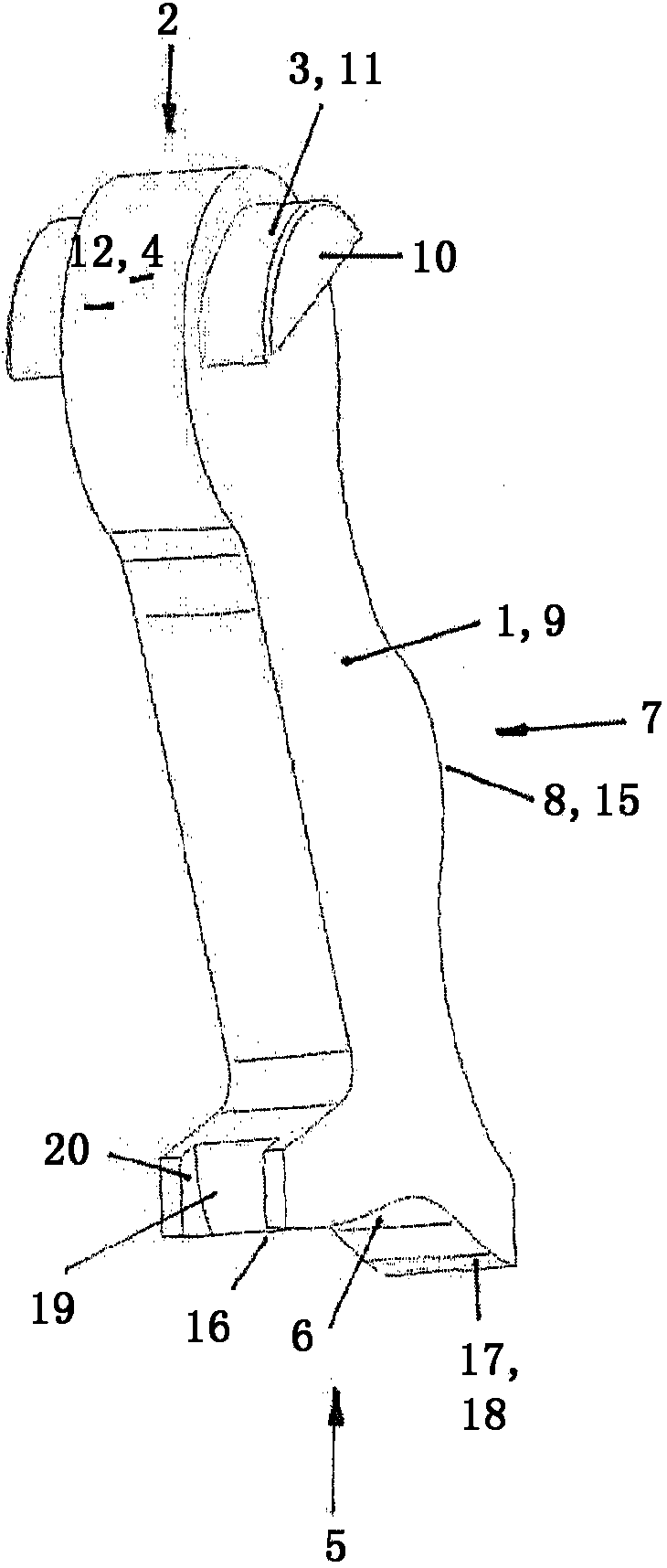

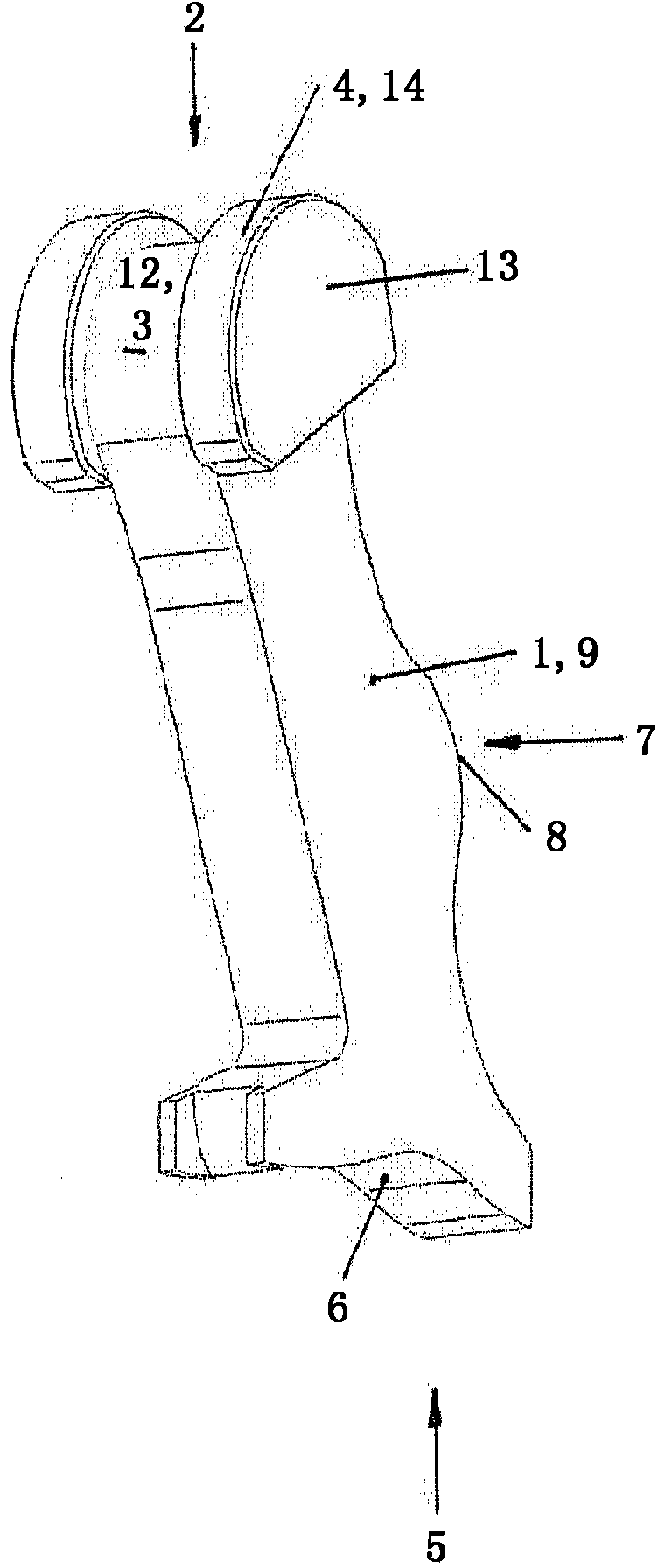

[0018] An intermediate lever 1 for a variable valve drive of an internal combustion engine is shown. The intermediate lever has a closed beam-like geometry and is stamped from sheet steel.

[0019] according to figure 1 , the intermediate lever 1 has, in the region of the positive end 2 , a support surface 3 for the link guide, which is fixed in one piece and is present as a sliding surface. The support surface 3 is composed of two fan-like projections 10 , which lie at a positive end 2 on the outer wall 9 extending parallel to the pivoting direction of the lever. The projections 10 each have an upper peripheral section 11 for the bearing of the link rail. In addition, a contact surface 4 for the cam disc, which is enclosed by the projection 10 and is configured as a sliding surface, extends over this positive end 2 , which extends beyond the projection 10 and serves as a frontal projection of the lever material. It exists from the part 12.

[0020] At the other positive e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com