Method for compensating finish rolling gap during mixed stainless steel rolling

A compensation method, stainless steel technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of scrap, low thickness accuracy, and reduced equipment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Switching between SPAH and TTS443 during finishing rolling in embodiment 1

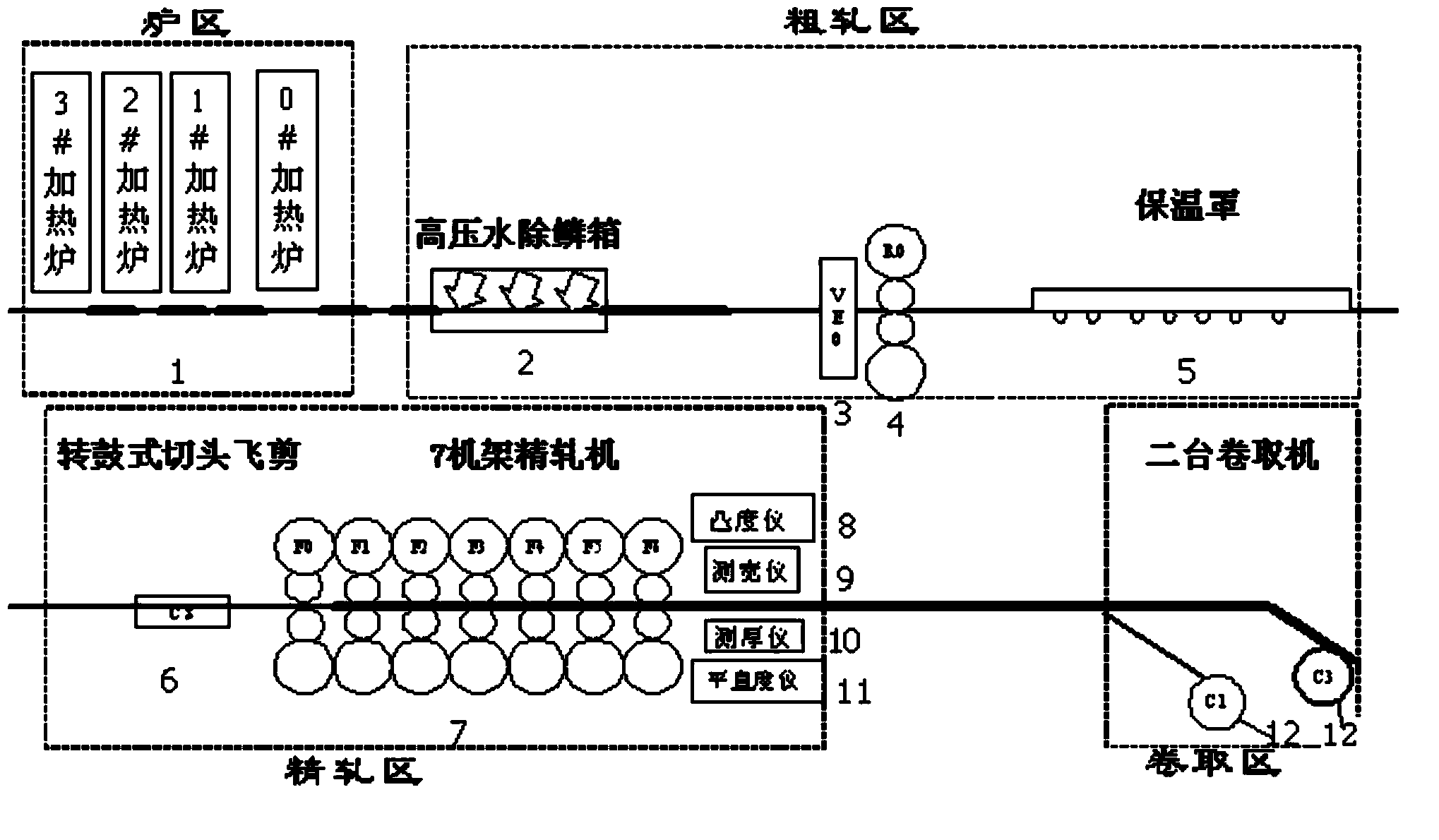

[0100] according to figure 1The process of switching between SPAH and TTS443 continuous casting slabs, the dimensions of the SPAH and TTS443 continuous casting slabs are: thickness 220mm, width 1280mm, length 9.4m and thickness 200mm, width 1280mm, length 8.6m. The control system of this embodiment adopts two levels of computer control, that is, process control computer (L2 computer) control and basic automation computer (L1) control. Replace the work roll of the finishing mill, and re-determine the zero position of the roll gap of the rolling mill according to the rolling force and oil column difference on both sides of the rolling mill.

[0101] Heat SPAH and TTS443 continuous casting slabs in heating furnaces 0 and 1# respectively, wherein the heating temperature of 0# heating furnace is 1250 ° C, and the heating time is 200 minutes; the heating temperature of 1 # heating furnace is 1200 ° ...

Embodiment 2

[0110] Example 2 Switching between T510L and SUS304 during finish rolling

[0111] The present embodiment adopts the substantially same processing method as embodiment 1, and difference is:

[0112] The dimensions of T510L and SUS304 continuous casting slabs are: thickness 220mm, width 1310mm, length 6.89m and thickness 180mm, width 1240mm, length 9.6m.

[0113] After rolling by the roughing mill, the obtained T510L strip steel has a thickness of 40mm, a width of 1300mm, and a temperature of 1080°C, and a SUS304 strip steel has a thickness of 37mm, a width of 1250mm, and a temperature of 1090°C.

[0114] After rolling by the finishing mill, the obtained T510L strip steel has a thickness of 2.91mm, a width of 1300mm, and a temperature of 900°C, and a SUS304 strip steel has a thickness of 3.0mm, a width of 1240mm, and a temperature of 980°C.

[0115] The chemical composition factor alpha of T510L strip steel is 1.09, and the chemical composition factor alpha of SUS304 strip ste...

Embodiment 3

[0119] SPHC and 00CR18MO2 switching during finish rolling in embodiment 3

[0120] The present embodiment adopts the substantially same processing method as embodiment 1, and difference is:

[0121] The dimensions of SPHC and 00CR18MO2 continuous casting slabs are: thickness 220mm, width 1250mm, length 9.4m and thickness 200mm, width 1240mm, length 8.6m.

[0122] After rolling by the roughing mill, the obtained SPHC strip has a thickness of 45mm, a width of 1250mm, and a temperature of 1080°C. The 00CR18MO2 strip has a thickness of 33mm, a width of 1255mm, and a temperature of 1060°C.

[0123] After rolling by the finishing mill, the obtained SPHC strip has a thickness of 4.9mm, a width of 1250mm, and a temperature of 860°C. The 00CR18MO2 strip has a thickness of 3.9mm, a width of 1255mm, and a temperature of 860°C.

[0124] The chemical composition factor alpha of SPHC strip steel is 0.73, and the chemical composition factor alpha of 00CR18MO2 strip steel is 0.88. According...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com