Rolling pressure compensation method of finish rolling rack

A technology of rolling pressure and compensation method, which is applied in the direction of tension/pressure control, etc., and can solve the problems of failing to meet the requirements of product accuracy and reducing equipment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

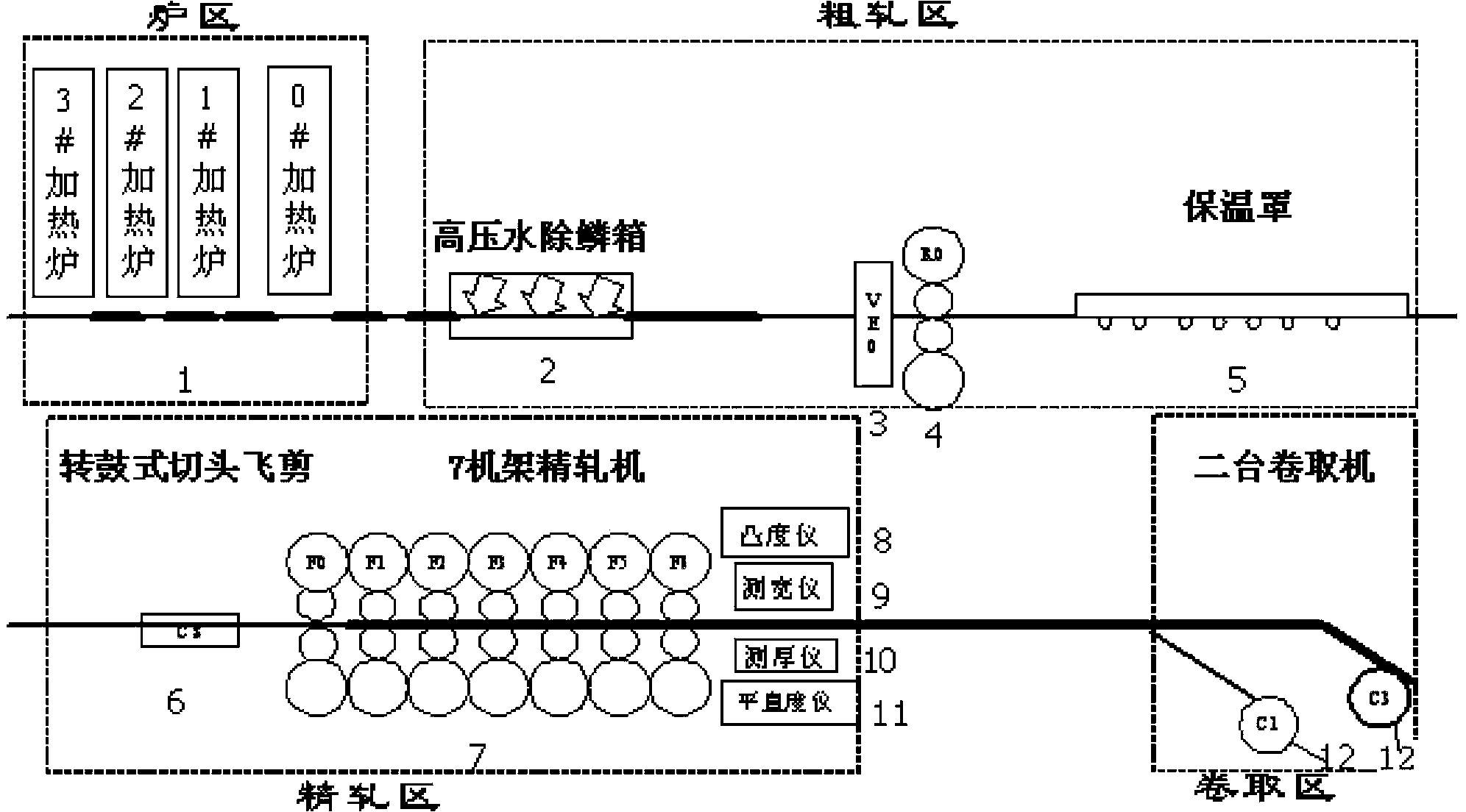

[0096] according to figure 1 The process of switching between DT4C and SPHC continuous casting slabs, the dimensions of the DT4C and SPHC continuous casting slabs are: thickness 220mm, width 1270mm, length 8.2m and thickness 220mm, width 1280mm, length 9.4m. The control system of this embodiment adopts two levels of computer control, that is, process control computer (L2 computer) control and basic automation computer (L1) control. Replace the work roll of the finishing mill, and re-determine the zero position of the roll gap of the rolling mill according to the rolling force and oil column difference on both sides of the rolling mill.

[0097] The DT4C and SPHC continuous casting slabs are heated in the heating furnaces 0# and 1# respectively. The heating temperature of the 0# heating furnace is 1050 °C and the heating time is 220 minutes; the heating temperature of the 1# heating furnace is 1250 °C. The heating time was 200 minutes.

[0098] After heat treatment, the DT4C ...

Embodiment 2

[0115] The present embodiment adopts the substantially same processing method as embodiment 1, and difference is:

[0116] The dimensions of DT4C and SPAH continuous casting slabs are: thickness 220mm, width 1270mm, length 8.2m and thickness 220mm, width 1280mm, length 9.4m. .

[0117] After rolling by the roughing mill, the obtained DT4C strip steel has a thickness of 47mm, a width of 1250mm, and a temperature of 1030°C. The SPAH strip steel has a thickness of 40mm, a width of 1250mm, and a temperature of 1100°C.

[0118] During the finishing rolling process, the reduction rates of DT4C and SPAH in each finishing stand are as follows:

[0119]

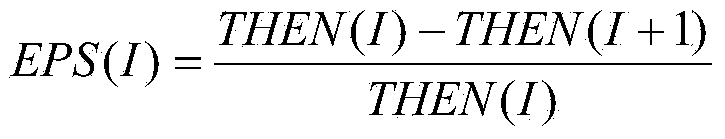

[0120] For DT4C strip steel, according to its 15 chemical components: C, Si, Mn, P, S, Al, Cr, Cu, Mo, Ti, Ni, V, Nb, N, B, from the pressure correction coefficient NNFKORR(Ia) Take the pressure correction coefficient NNFKORR (Ia) of each frame of the latest 100 pieces of steel with the same chemical composition in the database, ...

Embodiment 3

[0126] The present embodiment adopts the substantially same processing method as embodiment 1, and difference is:

[0127] The dimensions of SPAH and ICR6SI2MO continuous casting slabs are: thickness 220mm, width 1280mm, length 9.4m and thickness 200mm, width 1260mm, length 7.8m. .

[0128] After rolling by the roughing mill, the obtained SPAH strip has a thickness of 40mm, a width of 1250mm, and a temperature of 1100°C. The ICR6SI2MO strip has a thickness of 35mm, a width of 1250mm, and a temperature of 1130°C.

[0129] After rolling by the finishing mill, the obtained SPAH strip has a thickness of 2.75mm, a width of 1250mm, and a temperature of 860°C. The ICR6SI2MO strip has a thickness of 4.92mm, a width of 1250mm, and a temperature of 920°C.

[0130] During the finishing rolling process, the reduction rates of SPAH and ICR6SI2MO in each finishing stand are as follows:

[0131]

[0132] The chemical composition factor alpha of the SPAH strip is 1.03, and the chemical c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com