Rocker-type compression roller thrust support

A rocker type and pressure roller technology, which is applied in the field of steel rolling equipment, can solve the problems of affecting the forming effect of sheet metal parts, the relative distance is time-consuming and laborious, and the adjustment distance is inaccurate, so as to achieve convenient and firm adjustment up and down, and prevent the adjustment distance from being too large , good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments.

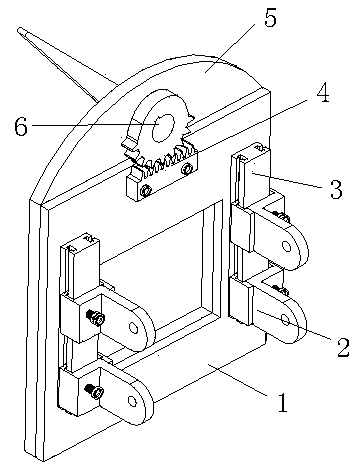

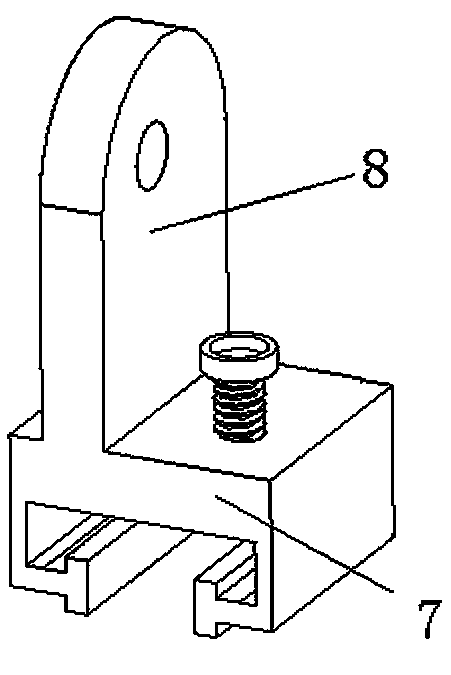

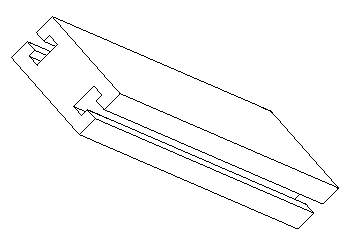

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a rocker-type pressure roller thrust bracket includes a pressure roller fixing plate 1 and a backing plate 5. The pressure roller fixing plate 1 is provided with a rectangular feeding port, a pressure roller mounting seat 2, a track block 3 and a straight rack 4. The rectangular feeding port is located in the middle of the pressure roller fixing plate 1; the straight rack 4 is fixed on the upper end of the pressing roller fixing plate 1; there are two track blocks 3, which are respectively fixed on both sides of the rectangular feeding port; the track block 3 is a cuboid structure, its two sides are vertically provided with "T"-shaped grooves in cross-section; the pressure roller mounting seat 2 includes a pressure roller bracket 8, a base 7 and a guide block, and the base 7 is a "冂"-shaped structure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com