Multifunctional processing device for precision metal structural parts

A technology for metal structural parts and processing devices, which is applied in metal processing equipment, machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, etc. On the surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

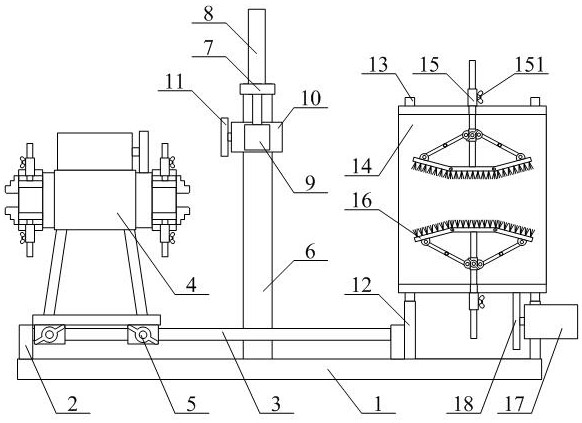

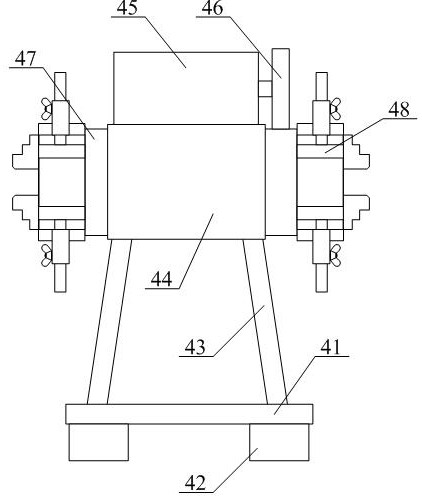

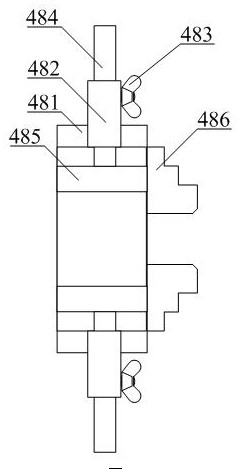

[0034] as attached figure 1 And attached figure 2As shown, a multifunctional processing device for precision metal structural parts, including a base 1, a vertical mounting plate 2, a sliding rod 3, a drive shaft clamping mobile frame structure 4, clamping bolts 5, a rear column 6, and a top plate 7 , cylinder 8, angle adjustment motor 9, grinding motor 10, precision grinding wheel 11, mounting bracket 12, fixed ring 13, cleaning frame mounting tube 14, telescopic tube 15, transmission shaft cleaning mounting frame structure 16, transmission motor 17 and a first-class Gear 18, the mounting riser 2 is welded respectively on the left and right sides of the upper, front and rear ends of the base 1; the slide bar 3 is bolt-connected to the inner upper part of the mounting riser 2; the transmission shaft clamps the moving frame The structure 4 is socketed on the upper part of the slide bar 3; the clamping bolts 5 are threadedly connected to the lower left and right sides of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com