Fully-automatic edge rolling machine

A rolling machine, fully automatic technology, used in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of time-consuming, labor-intensive, and low production efficiency in the rolling process, reducing defective products, improving efficiency, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

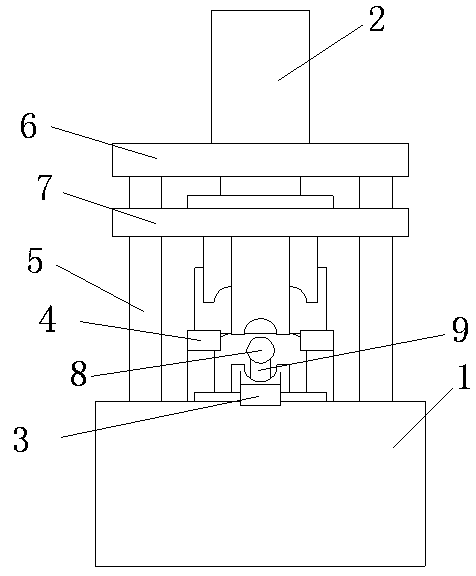

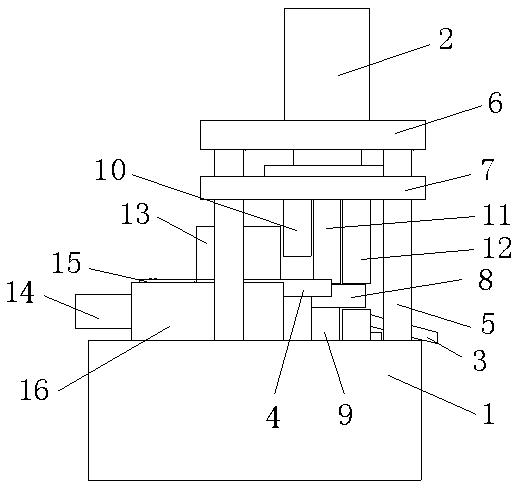

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] As shown in the figure, the fully automatic round rolling machine of the present invention includes a workbench 1, a mold pneumatic transmission device 2, a mold group and a feeding mechanism, and the four corners of the workbench 1 are respectively provided with uprights 5, and the uprights 5 A top plate 6 is fixed above, and the mold pneumatic transmission device 2 is fixed on the top plate 6. The mold group includes a flanging mold 10, a semicircular bending mold 11 and a rolling mold 12, and the flanging mold 10, semicircular bending mold 11 And rolling mold 12 is arranged in order from back to front, and described edge bending mold 10 comprises upper mold and lower mold, and described bending semicircle mold 11 comprises upper mold and support seat 9, and the center also is provided with circular mandrel 8, so The rolling mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com