Machine tool and method for ejecting workpiece parts

A technology for workpieces and machine tools, applied in the field of sheet metal, can solve the problems of inability to ensure the positioning of the release device and large tolerances of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

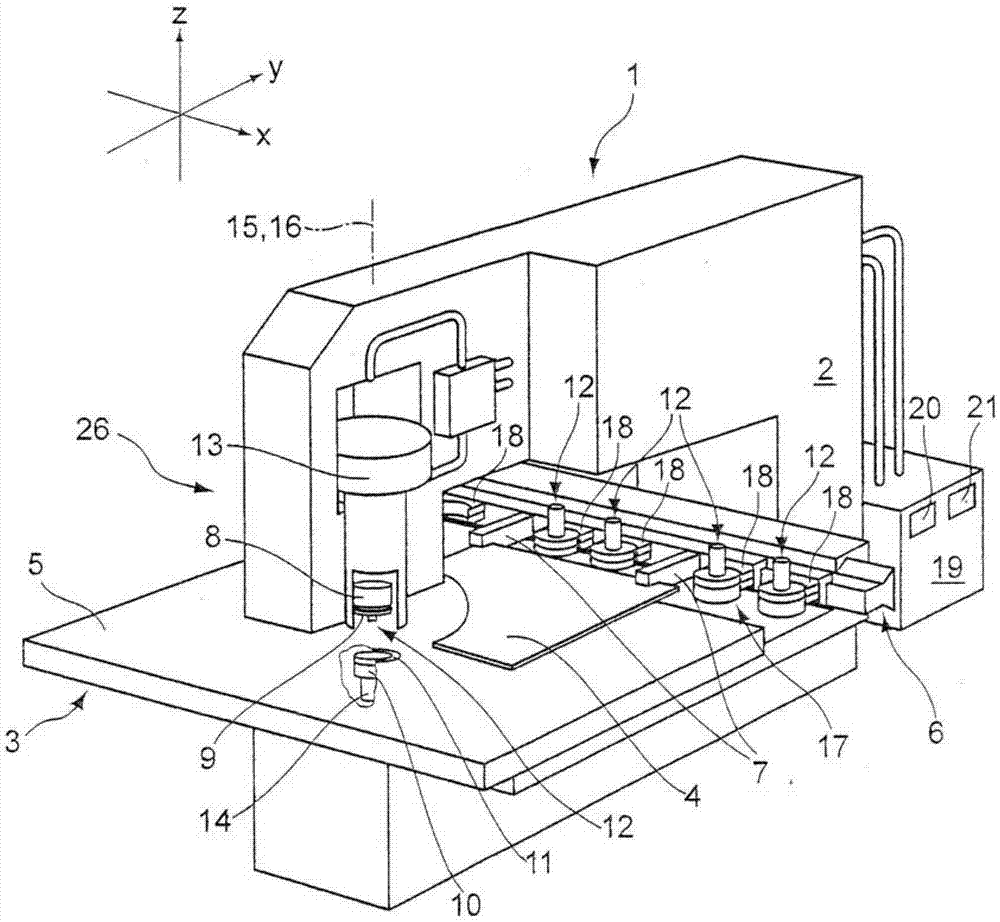

[0033] figure 1 A machine tool 1 is shown for the cutting and / or forming of sheet metal workpieces in the form of a punching / forming machine for processing sheet metal. The punching / forming machine 1 has a C-shaped frame 2 , in the pharynx of which is arranged a workpiece support in the form of a workpiece table 3 for supporting a workpiece to be processed in the form of a sheet metal 4 . The workpiece table 3 forms on its upper side a horizontal support plane 5 for the sheet metal 4 to be processed, which is parallel to the figure 1 The x / y plane orientation of the coordinate system shown in . The sheet metal 4 clamped by the clamping jaws 7 can be moved in the support plane 5 of the workpiece table 3 by means of the coordinate guidance device 6 .

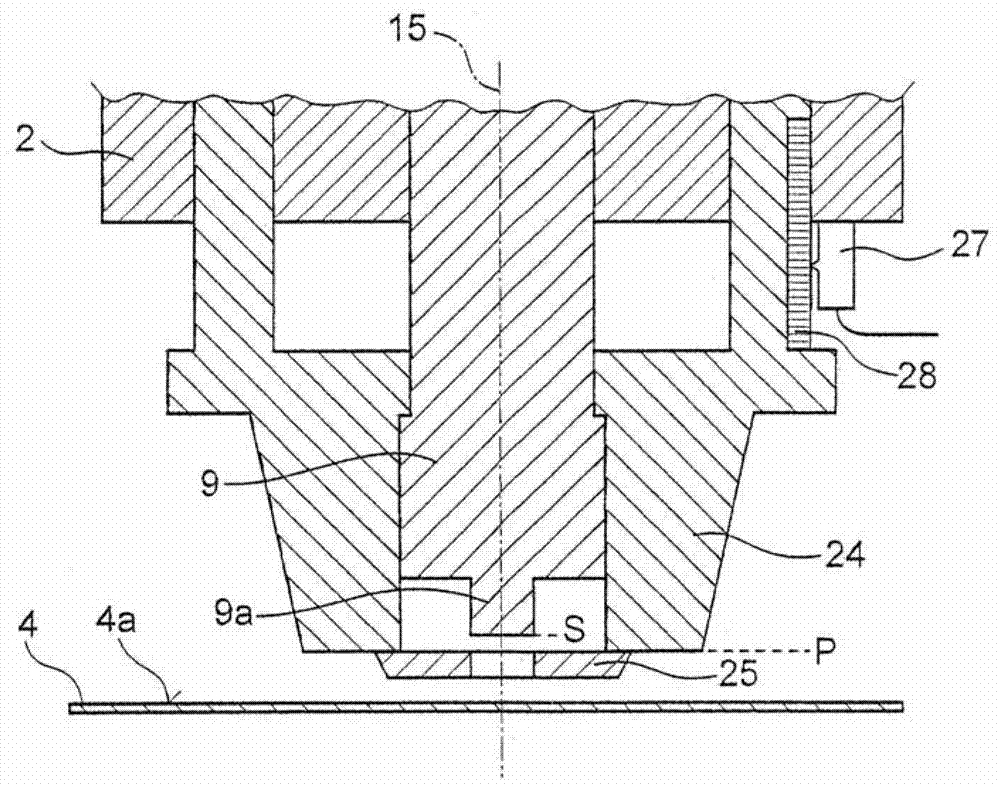

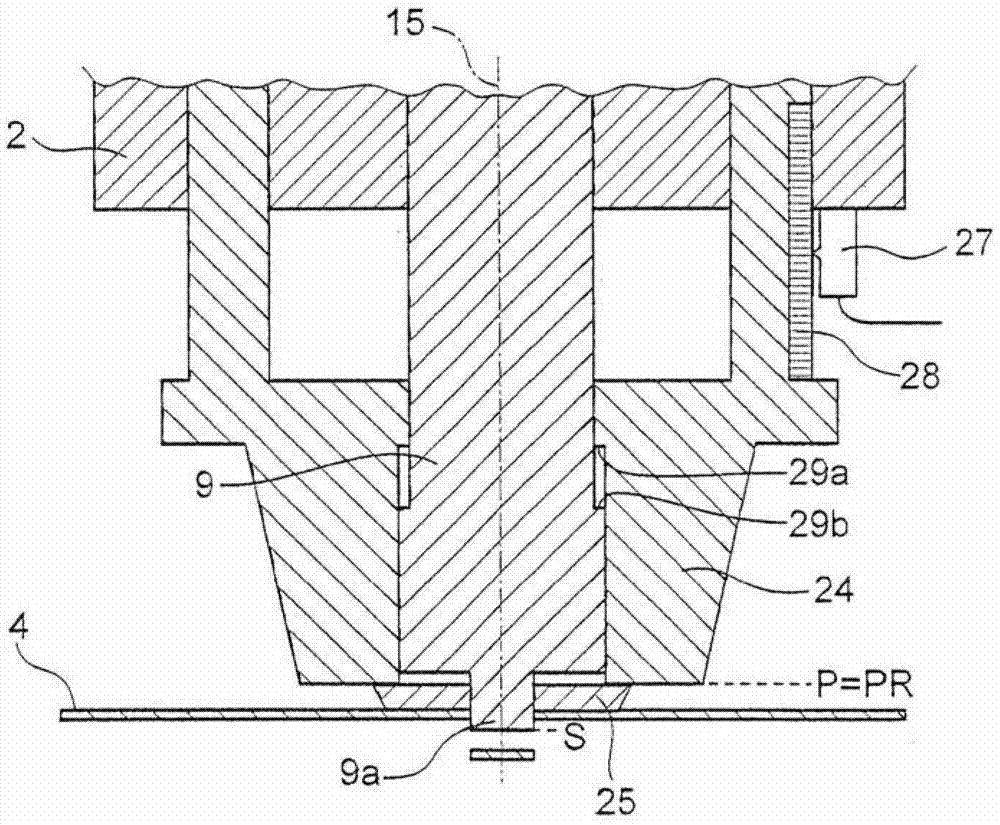

[0034] Arranged on the front end of the upper leg of the C-shaped frame 2 is a punch receiver 8 in which a punch punch 9 is mounted. Furthermore, on the front end of the lower leg of the C-shaped frame 2 there is arranged a die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com