System for automatically assembling plastic cap and nail

An automatic assembly, plastic cap technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency and high labor intensity

Inactive Publication Date: 2014-01-15

HEBEI AGRICULTURAL UNIV.

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The manual method has low assembly efficiency and high labor intensity, so an automated assembly equipment is urgently needed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

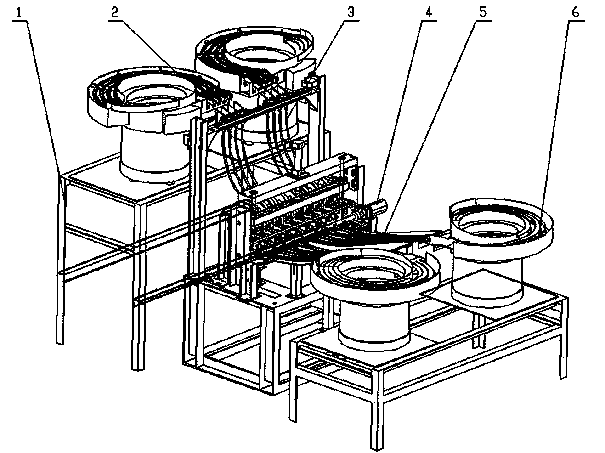

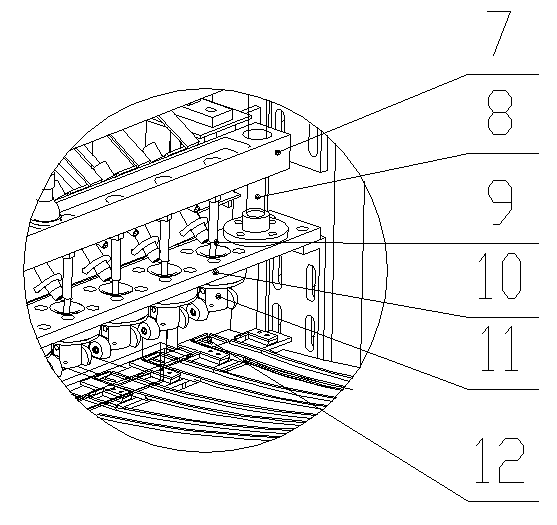

The invention relates to an automatic assembling system. A system for automatically assembling plastic caps and nails comprises vibrating discs, a support, a punch fixing beam, punches, slide ways, nail receiving bowls and assembling tables, wherein the plastic caps and the nails can be automatically assembled. The nails and the plastic caps can be orderly outputted through the vibrating discs and enter the assembling tables through the slide ways, the punch fixing beam drives the punches to press the nails into the plastic caps respectively, and therefore the nails and the plastic caps can be assembled together. The system can achieve automatic assembly of the plastic caps and the nails, and labor is saved.

Description

[0001] technical field [0002] The invention relates to an automatic assembly device, in particular to an automatic machine for assembling plastic caps and nails. Background technique [0002] Wooden house construction, wooden shed construction, and interior decoration all require a nail with a plastic cap for fixing. At present, most of the assembly of plastic caps and nails is done by hand, and there is no special machine. The manual method has low assembly efficiency and high labor intensity, so an automated assembly equipment is urgently needed. Contents of the invention The object of the present invention is to address the above problems and provide an automatic assembly system, which includes a vibrating plate, a bracket, a punch fixing beam, a punch, a slideway, a nail bowl, and an assembly table, which can complete the automatic assembly of plastic caps and nails . The ordered nails and plastic caps output by the vibrating plate enter the nail bowl and the as...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P19/02

CPCB23P19/02B23P19/004

Inventor 张秀花弋景刚姜海勇崔保健邢雅周王泽河

Owner HEBEI AGRICULTURAL UNIV.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com