Electronic torque tool with multiplier automatic compensation device and its operating method

A torque tool and automatic compensation technology, applied in the field of torque tools, can solve problems such as error-prone, inconvenient, screw or thread collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed content and technical description of the present invention are now further described with examples, but it should be understood that these examples are for illustrative purposes only and should not be construed as limitations on the implementation of the present invention.

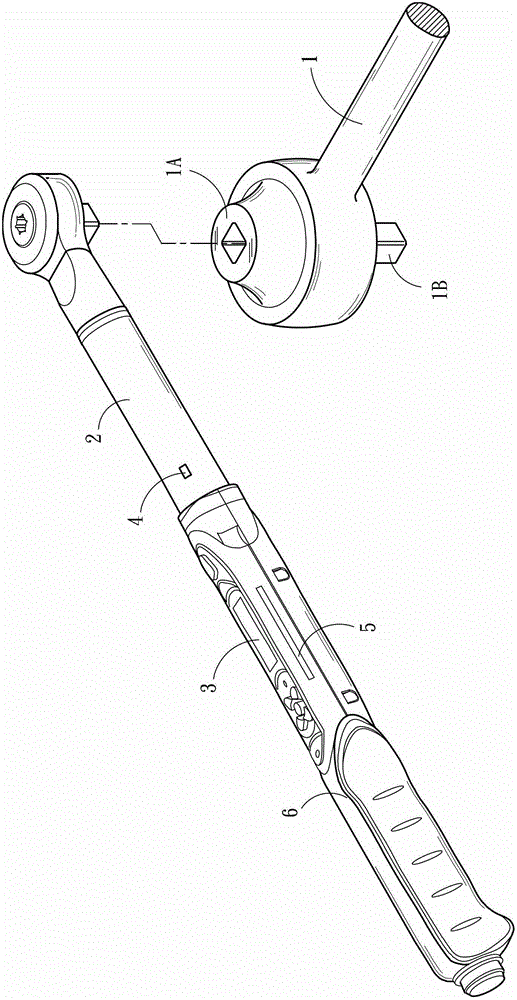

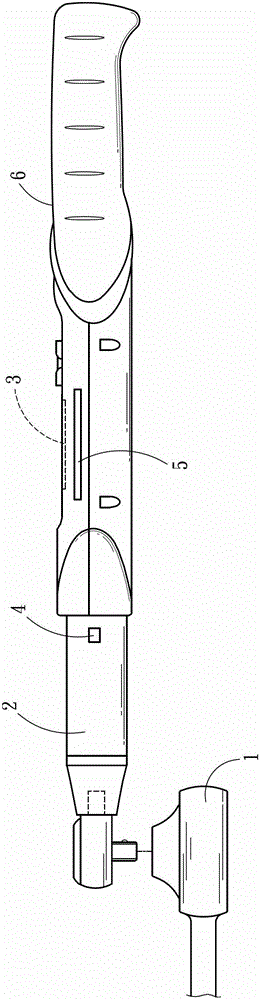

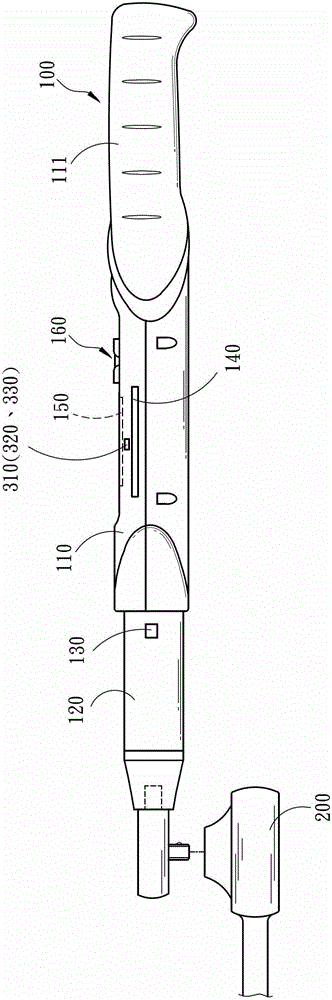

[0021] see image 3 As shown, the present invention is an electronic torque tool with a force multiplier automatic compensation device, which includes at least one replaceable force multiplier 200, an electronic torque tool 100 with a replaceable force multiplier 200, a torque The override setting module 310 , a torque override compensation conversion module 320 and a torque operating range conversion module 330 .

[0022] The electronic torque tool 100 further includes a housing 110 , a torsion bar 120 , a torque detection element 130 , a control system 140 , a display element 150 , and a setting element 160 . Wherein the housing 110 has a grip 111 for gripping, one end of the torsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com