Microphone support for in-vehicle acoustic mode measurement and testing

A technology for microphones and tests, applied in the direction of machines/brackets, supporting machines, mechanical equipment, etc., can solve the problems of limited vehicle models, difficult installation, and difficulty in ensuring the position accuracy of microphones, and achieve easy processing, simple structure, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

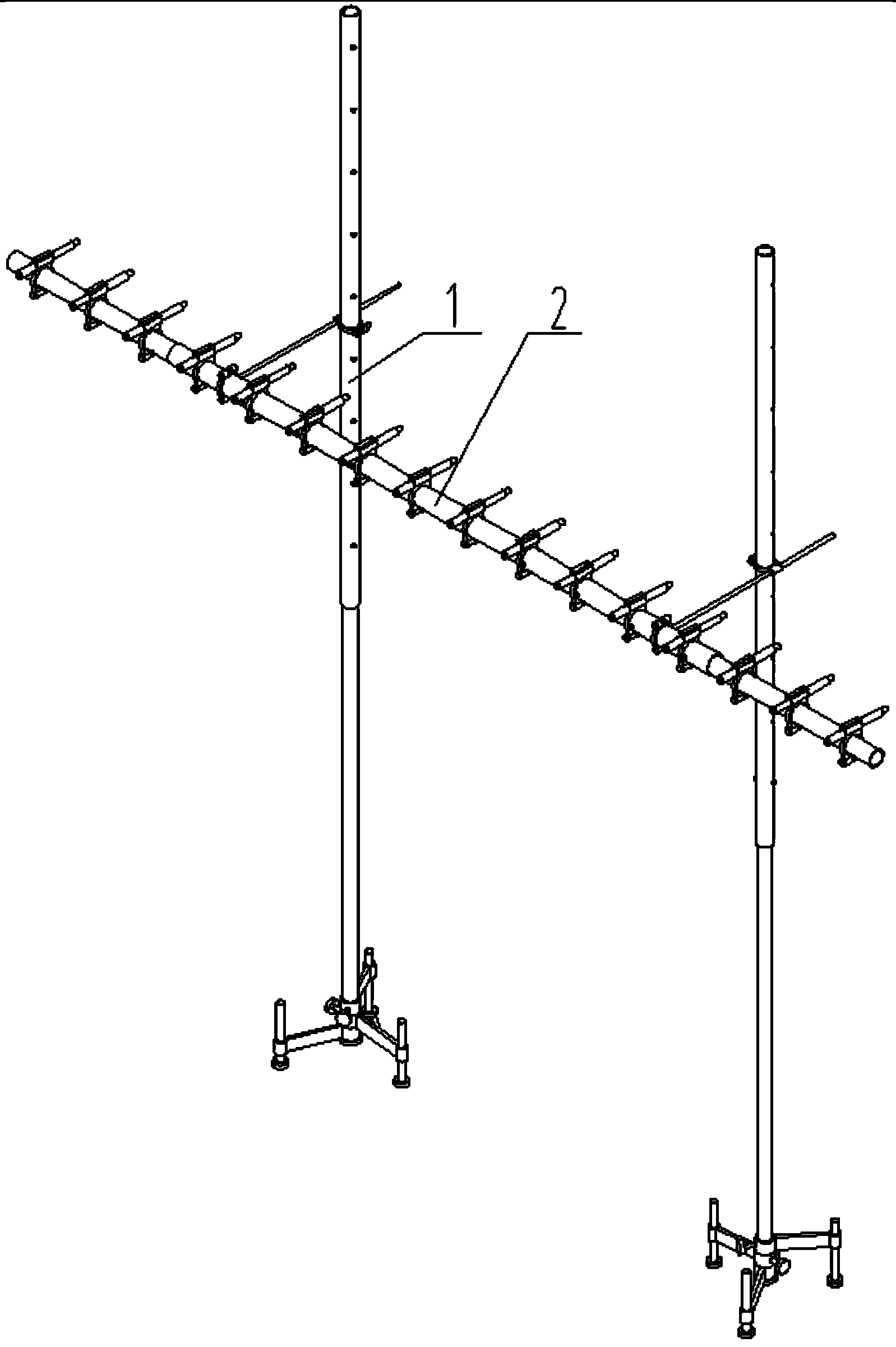

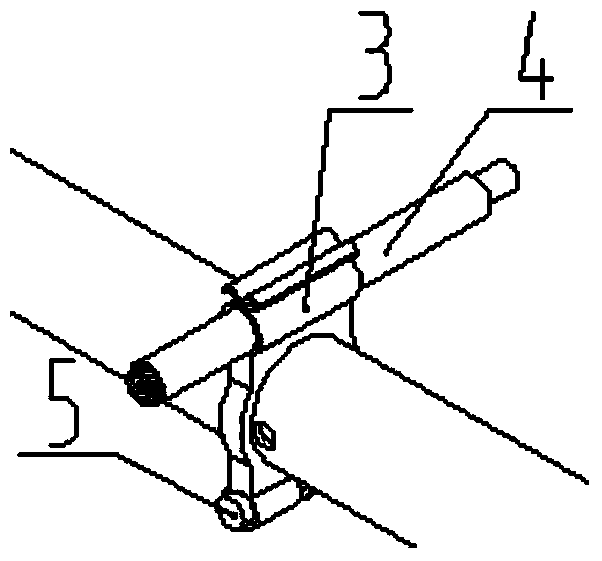

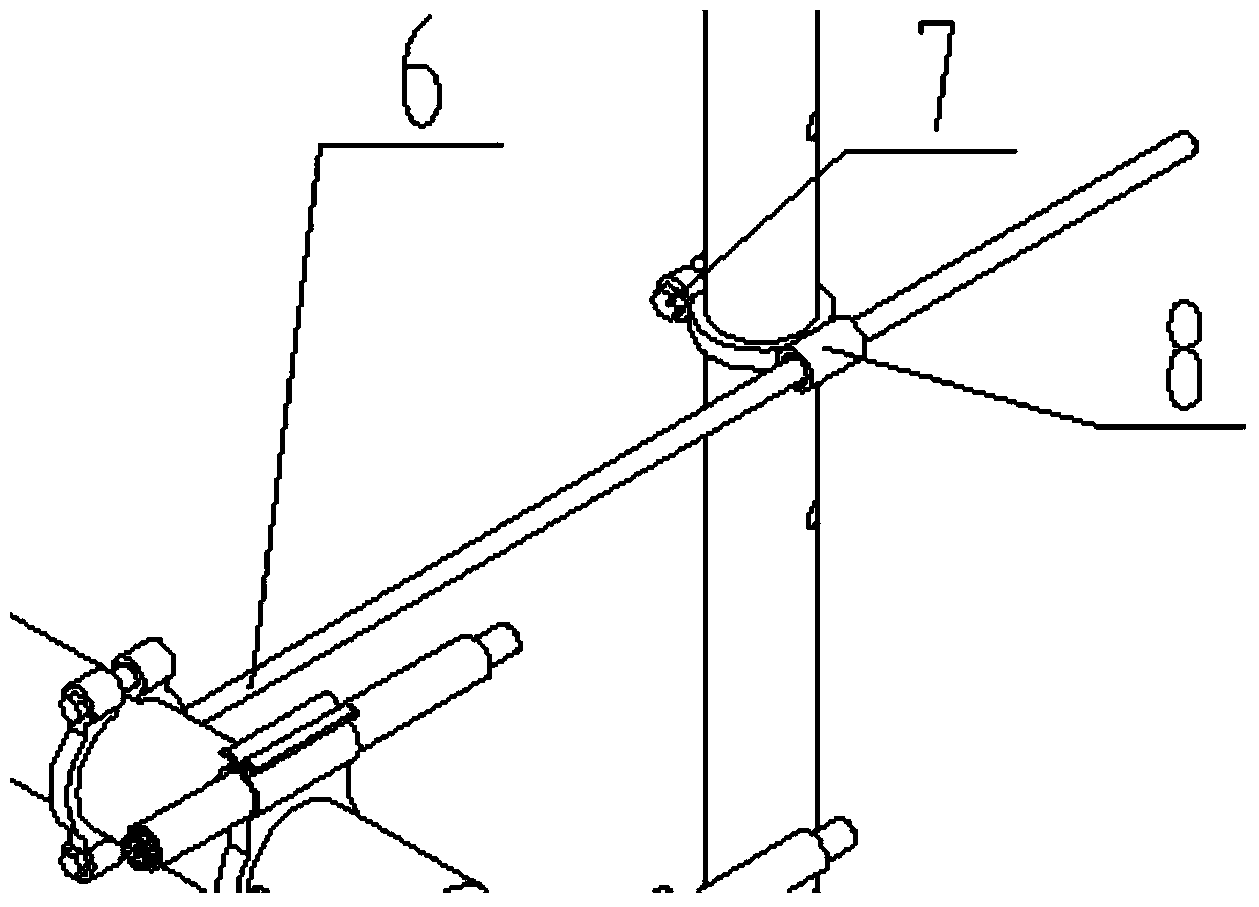

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 9 Describe this embodiment, the microphone bracket for the acoustic mode measurement test in the vehicle, including the main bracket 1, the auxiliary bracket 2, the microphone positioning clip 3, the microphone 4, the screw 5A, the connecting rod 6 of the main and auxiliary bracket, the bolt 7, and the connecting rod clamp 8 , foot bracket components and other main components. Wherein the microphone is installed on the auxiliary bracket 2 by the microphone positioning clip 3, the main bracket 1 and the auxiliary bracket 2 are connected by the main and auxiliary bracket connecting rod 6, one end of the connecting rod is connected to the auxiliary bracket by a bolt, and the other end is connected by a connecting rod clamp 8 The main bracket 1; the connecting rod clamp 8 is adjusted with nuts to ensure that the auxiliary bracket 2 can adjust its position in the vertical direction; the auxiliary bracket 2 is ma...

specific Embodiment approach 2

[0019] Embodiment 2. This embodiment is the installation and use method of the microphone bracket for the acoustic modal measurement test in the vehicle described in Embodiment 1. The specific process is:

[0020] 1. Adjust the angle and height of the three foot brackets on both sides so that the microphone bracket can be stably supported;

[0021] 2. Adjust the telescopic length of the guide rod in the main and auxiliary brackets according to the height and width that the microphone needs to be arranged;

[0022] 3. Select the number of microphones and the installation interval according to the needs, and install the microphones;

[0023] 4. Adjust the height of the microphone by adjusting the height of the auxiliary bracket during the measurement process;

[0024] 5. Change the position of the microphone bracket, and repeat the above steps until the sound pressure measurement is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com