Coal and rock mass stress orientation monitoring method and device

A monitoring device and technology for coal and rock mass, which are applied in the measurement of force components and hydraulic/pneumatic force measurement, etc., can solve the problems of poor adaptability and timeliness, complicated stress testing, and difficult operation, etc., so as to achieve less impact on production and reduce Effectiveness of testing workload, installation and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

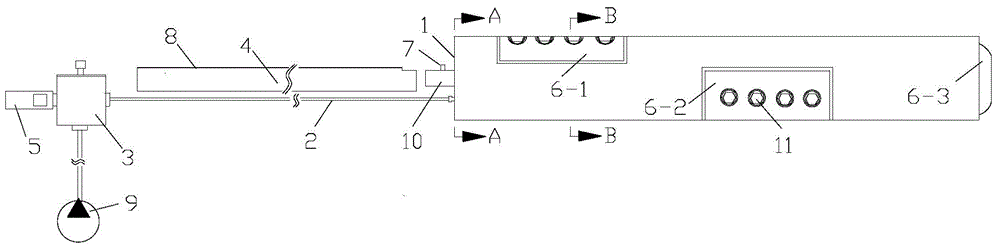

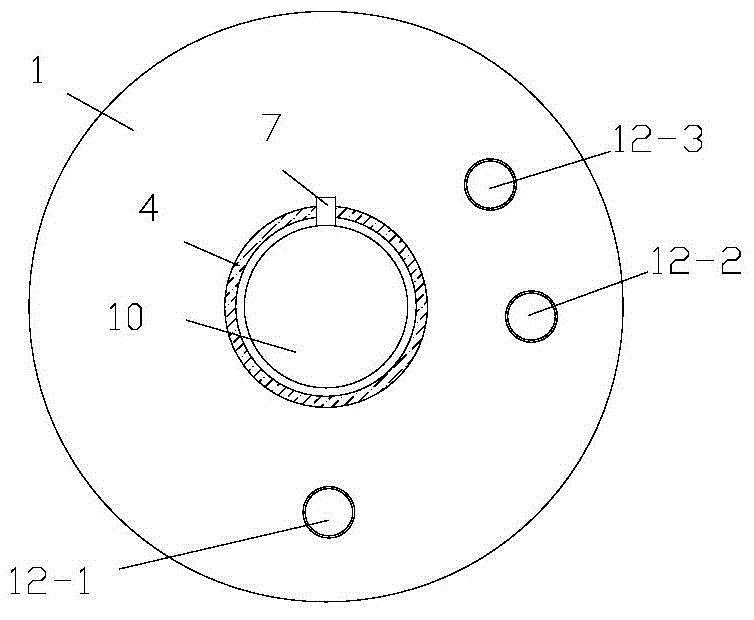

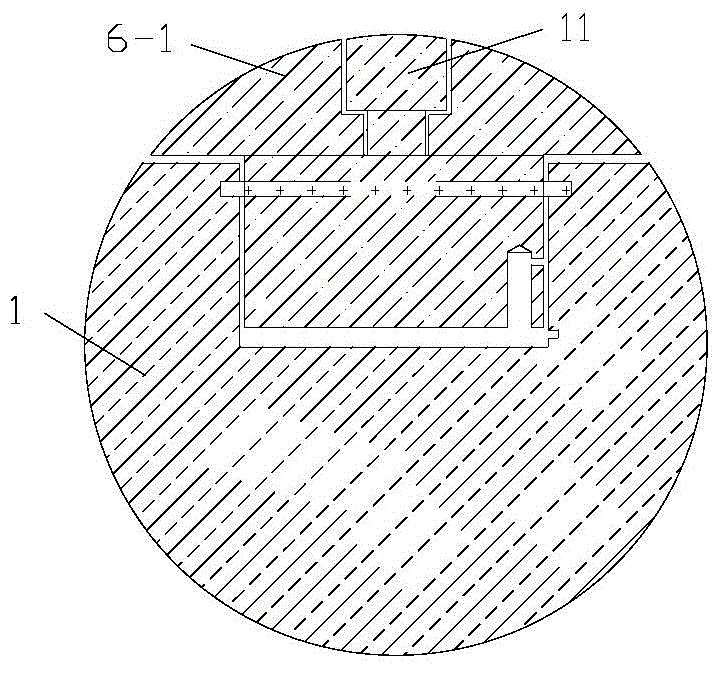

[0027] Embodiment 1, as figure 1As shown, the coal and rock mass stress directional monitoring device of the present invention is mainly composed of a three-way cylinder pressure sensor 1, a high-pressure oil pipe 2 and a three-way valve 3. The high-pressure oil pump 9 and the installation guide rod 4 are used as supporting tools. The sensor 1 is installed in the coal rock mass by installing the guide rod 4, and the cylinder body pressure sensor 1 is provided with three piston induction plates, and the three piston induction plates are respectively connected through the fixing nut 11 to each independently installed in the cylinder body pressure sensor. The piston cylinder in 1, the three piston induction sheets include the first piston induction sheet 6-1, the second Piston induction piece 6-2 and the third piston induction piece 6-3; The junction of cylinder body pressure sensor 1 and installation guide rod 4 is provided with installation rod joint 10, and installation rod jo...

Embodiment 2

[0037] Embodiment 2. According to the actual monitoring needs, if only one direction needs to be monitored, only one piston sensing plate and the piston cylinder connected to it can be set on the cylinder body pressure sensor 1, such as image 3 shown. Others are the same as in Embodiment 1, omitted.

Embodiment 3

[0038] Embodiment 3, according to the actual monitoring needs, if only two directions need to be monitored, only two piston sensing plates and the piston cylinders respectively connected to it can be arranged on the cylinder body pressure sensor 1, such as Figure 4 shown. Others are the same as in Embodiment 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stress concentration factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com