Coal-rock mass ground stress continuous testing device and method thereof

A testing device and testing method technology, applied in hydraulic/pneumatic measurement and other directions, can solve problems such as poor initial adaptability, achieve real-time testing, reduce testing workload, and operate quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

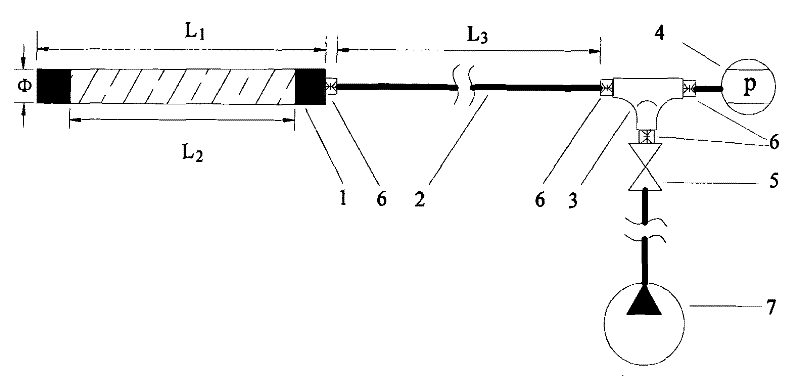

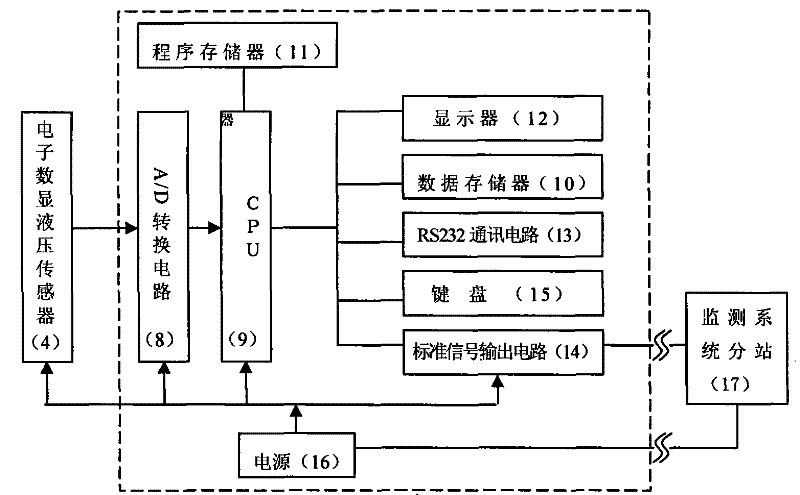

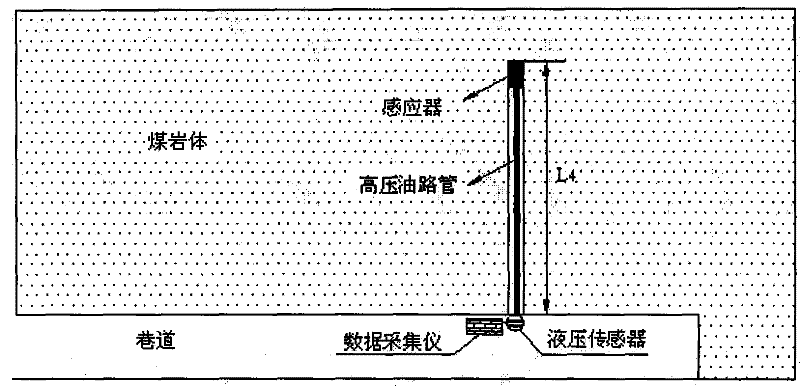

[0061] The present invention is mainly composed of three parts: a ground stress sensor, a data acquisition instrument and a high-pressure oil pump, which will be described separately below.

[0062] (1) Ground stress sensor

[0063] The ground stress sensor is composed of a front capsule pressure sensor 1, a high-pressure oil pipe 2, a tee 3, an electronic digital display hydraulic sensor 4, a valve 5 and a quick-change connector 6. The capsule pressure sensor 1 has a diameter of ф39~100mm and a full length of L 1 110~400mm, sensing part L 2 Length 70~320mm; high pressure oil pipe 2 length L 3 It is 0-50m, depending on site requirements; the electronic digital display hydraulic sensor 4 can be connected with the existing coal mine safety monitoring system substation, and the data can be transmitted to the ground monitoring host in real time, and then to the terminal computers; valve 5 It is a shut-off valve.

[0064] a. Capsule pressure sensor 1 adopts high pressure expansion hose, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com