Infrared thermal imaging device and method for projective non-destructive detection of internal defects between film layers

A non-destructive testing and internal defect technology, applied in the direction of material defect testing, etc., can solve the problems of time-consuming, high cost, destructive processing, etc., and achieve the effect of improving sensitivity, short detection time, and eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

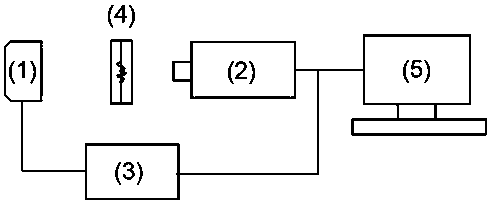

[0030] Specific implementation mode one: as figure 1 As shown, the infrared thermal imaging device for projective non-destructive detection of internal defects between film layers provided in this embodiment includes a flash light source 1, an infrared thermal imaging camera 2, a signal synchronization device 3, a tested part 4 and a computer 5, and a signal synchronization device 3 Connect with the flash light source 1 and the computer 5 respectively, the infrared thermal imager 2 is respectively connected with the computer 5 and the signal synchronization device 3, the detected part 4 is placed vertically between the infrared thermal imager 2 and the flash light source 1, and is connected with the infrared thermal image The lens of instrument 2 is parallel.

[0031] When the above detection device is in operation, the flash light source 1 instantly irradiates and heats the tested part 4 from the back of the tested part 4, and the temperature of the tested part 4 rises. Duri...

specific Embodiment approach 2

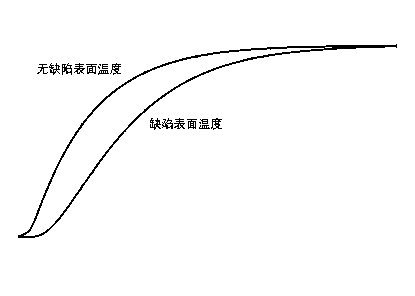

[0034] Specific implementation mode 2: This implementation mode provides a projective non-destructive infrared thermal imaging method for detecting internal defects between film layers, which is caused by the blockage of heat flow in the defective part of the multilayer film and the smooth passage of heat flow in the non-defective part when pulsed heating is used. The phenomenon of different surface temperatures identifies the location and size of the defect. The specific implementation steps are as follows:

[0035] 1. Preliminary calculation of the pulse time constant and pulse energy according to the thermal material characteristics of the multilayer film structure;

[0036] 2. Adjust the pulse time of the flash light source and the signal synchronization device;

[0037] 3. Place the tested part vertically in front of the thermal imaging camera to ensure that the tested part is parallel to the lens of the thermal imaging camera;

[0038] 4. The flash light source pulses ...

specific Embodiment approach 3

[0045] Specific implementation mode three: This implementation mode provides an infrared thermal imaging method for projection-type nondestructive detection of internal defects between film layers, and the specific implementation steps are as follows:

[0046] 1. Preparation of the inspected part: Electroplating on the substrate with Ni thin film and Cu film as the seed layer;

[0047] 2. Use a laser pulse with a spot diameter of 10mm and a wavelength of 808nm to heat the object to be tested, control the irradiation pulse time to 500μs, and the irradiation energy density to 20KJ / m 2 ;

[0048] 3. At the same time as the pulse heating, the infrared thermal imaging camera collects at least 5 pieces of temperature image data on the surface of the tested part within 1000μs of heating;

[0049] 4. Under the premise of sufficient cooling, steps 2 and 3 can be repeated many times, preferably 4 to 5 times;

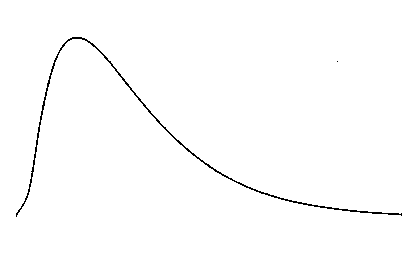

[0050] 5. Use a computer to superimpose and calculate the collected tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com