Method for predicting bundle vibration of large low-temperature evaporator under two-phase flow effect

A low-temperature evaporator, tube bundle vibration technology, used in vibration testing, testing of machine/structural components, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for predicting tube bundle vibration of a large cryogenic evaporator under the action of two-phase flow, comprising the following steps:

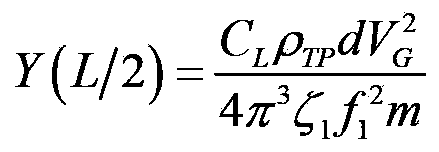

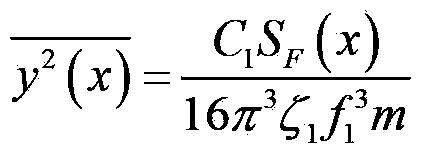

[0023] Step 1. Calculate the maximum amplitude Y(L2) of the heat exchange tube with simply supported boundary conditions:

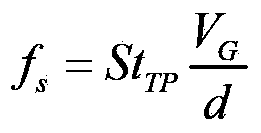

[0024] (1) Calculate the vortex shedding frequency according to the following formula:

[0025] f s = St TP V G d

[0026] In the formula:

[0027] St. TP is the Strohal number in the two-phase flow;

[0028] d is the diameter of the heat exchange tube;

[0029] V G is the flow velocity of the two-phase fluid in the pipe gap, in ms, calculated according to the following formula: V G =V TP P(P-d), where, V TP is the average velocity of the two-phase fluid; P is the tube spacing.

[0030] (2) Calculate the maximum amplitude of the heat exchange t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com