Self-balancing system for applying effective prestress to metal components

A metal component and self-balancing technology, which is applied in the testing of machines/structural components, testing of mechanical components, measuring devices, etc., can solve problems such as unsuitable metal components and difficulty in controlling the magnitude of the applied prestress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

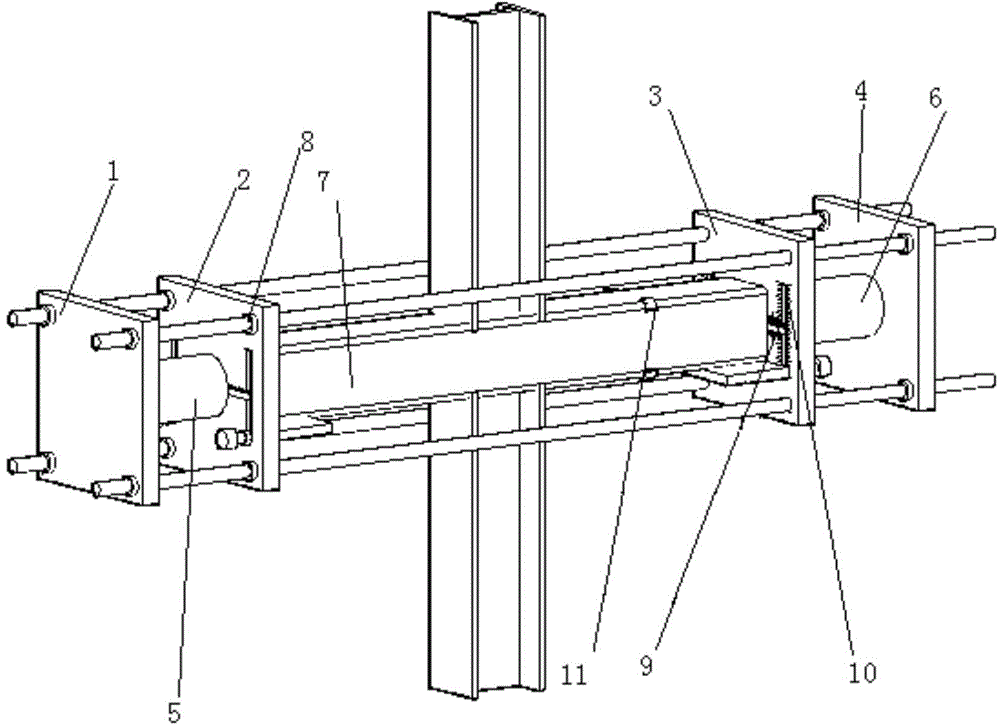

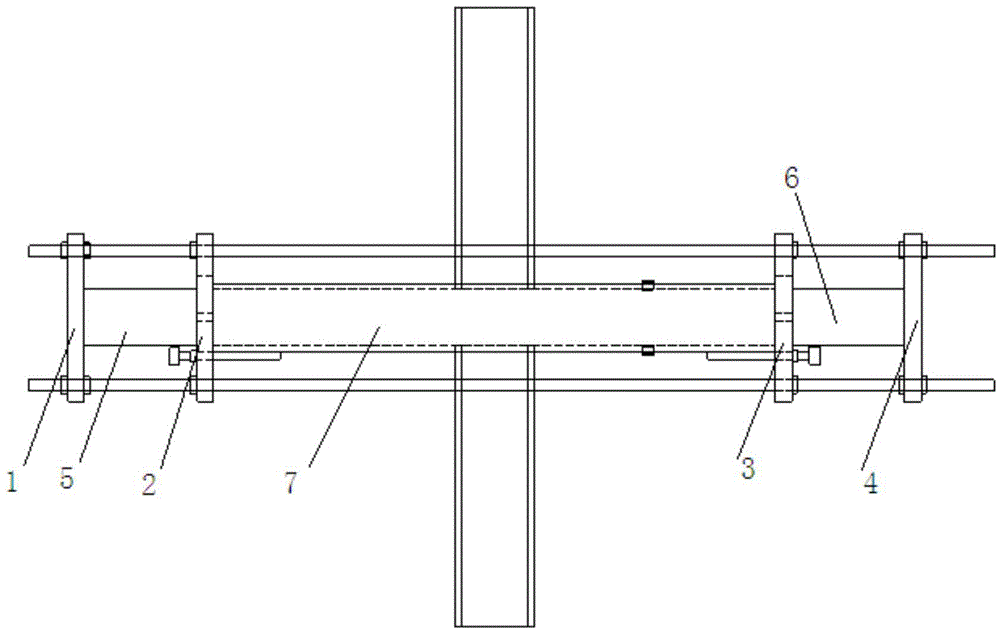

[0016] Referring to the accompanying drawings, the self-balancing system that applies effective prestress to metal components includes left outer high-strength metal plate 1, left inner high-strength metal plate 2, right outer high-strength metal plate 4, and right inner high-strength metal plate 3 with the same material and size. , a hydraulic jack 5 is sandwiched between the left outer high-strength metal plate 1 and the left inner high-strength metal plate 2, a load cell 6 is sandwiched between the right outer high-strength metal plate 4 and the right inner high-strength metal plate 3, and the left inner high-strength metal plate There is a test metal member 7 sandwiched between the metal plate and the right inner high-strength metal plate, and four corresponding holes are respectively opened on the left outer high-strength metal plate, the left inner high-strength metal plate, the right outer high-strength metal plate, and the right inner high-strength metal plate 8. Four h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com