Brake generator

A technology for generators and braking mechanisms, which is applied to motors, electromechanical devices, electric vehicles, etc. It can solve the problems of high heat generation and inability to work for a long time, and achieve the effect of stably controlling the speed of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

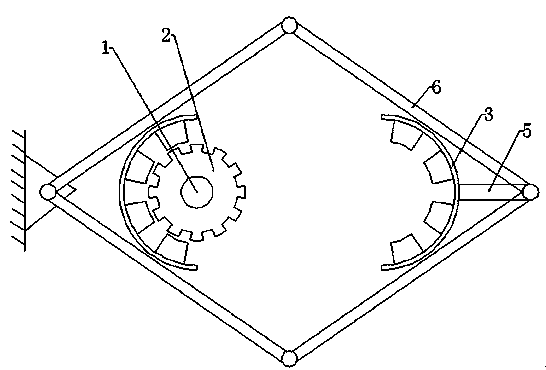

[0015] Embodiment 1; as figure 1 , the rotor 2 is installed on the vehicle axle 1, a semicircular stator 3 is fixedly installed on the left side of the rotor 2, and the other semicircular stator 3 is installed on the right side of the rotor 2 through a telescopic mechanism 5, which is hinged by four connecting rods 6. , the hinge point at the left end is fixed on the left side of the left semicircular stator 3 , and the semicircular stator 3 is installed on the hinge point on the right through the support rod 5 . There are permanent magnet poles on the semicircular stator 3, and a coil is wound on the rotor 2, and the coil is connected to a switching power supply. The switching power supply can adjust the output voltage of the coil to output a stable value. Automobile brakes are divided into two-stage brakes. The first-stage brakes control the distance between the semicircular stator 3 and the rotor 2, and the second-stage brakes are consistent with the existing brake pads. ...

Embodiment 2

[0018] The rotor 2 is installed on the vehicle axle 1, a semicircular stator 3 is fixedly installed on the left side of the rotor 2, and the other semicircular stator 3 is installed on the right side of the rotor 2 through a telescopic mechanism 5, which is hinged by four connecting rods 6. The hinge point at the left end is fixed on the left side of the left semicircular stator 3 , and the semicircular stator 3 is installed on the right hinge point through the support rod 5 . There are permanent magnet poles on the rotor 2, a coil is wound on the semicircular stator 3, the coil is connected with a switching power supply, and the switching power supply can adjust the output voltage of the coil to output at a stable value. Automobile brakes are divided into two-stage brakes. The first-stage brakes control the distance between the semicircular stator 3 and the rotor 2, and the second-stage brakes are consistent with the existing brake pads.

[0019] Working process: When the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com