Manufacturing method of binding plate for rabbit

A manufacturing method and binding technology, which are applied in the fields of animal restraint instruments, medical science, veterinary instruments, etc., can solve the problems of injection failure, broken needles, difficulty in blood collection, etc., and achieve a simple manufacturing method, simple structure, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

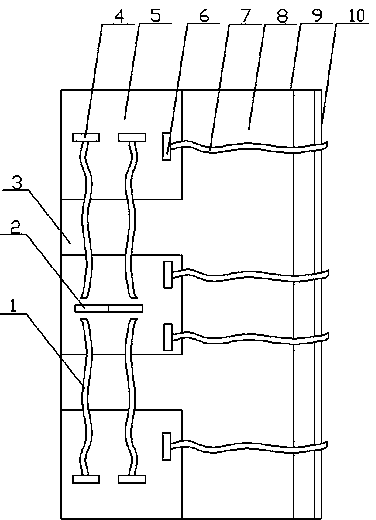

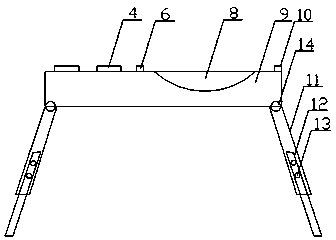

[0030] The present invention will be described below in conjunction with the accompanying drawings.

[0031] A method for manufacturing a rabbit binding plate, comprising the steps of:

[0032] A. Steps for preparing the board body: select a wooden board or plastic board with a thickness of 5-8cm as the board body, and prepare body fixing grooves and leg fixing grooves integrally formed on the board body. The width of the body fixing grooves is 10-15cm, two The distance between the two leg fixing slots is 15-20cm, so that the body fixing slots and the leg fixing slots are perpendicular to each other;

[0033] B. Steps to install the support: Connect the support column through the rotating shaft at the lower part of the board, and the extension rod is inserted into the support column. The extension rod is used to adjust the overall length of the support column, and the support column and the extension rod pass through Press buckle to lock and fix;

[0034] C. Steps to install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com