Horizontal hitting rod structure of press machine

A technology of presses and buffer blocks, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of endangering the physical and mental health of operating workers, passiveness, etc., and achieve simple structure and effective use Good results

Inactive Publication Date: 2014-01-22

XUZHOU CONTENT TRANSMISSION TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The function of the horizontal hitting rod in the mechanical press is to push out the workpiece or waste from the mold. The power of the horizontal hitting rod comes from the impact force of the straight hitting rods on both sides of the guide rail of the press. Since the straight hitting rod and the horizontal hitting rod are made of metal materials If so, the strong noise generated by the impact of the above two at work will directly endanger the physical and mental health of the operators, which will easily lead to passive work.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

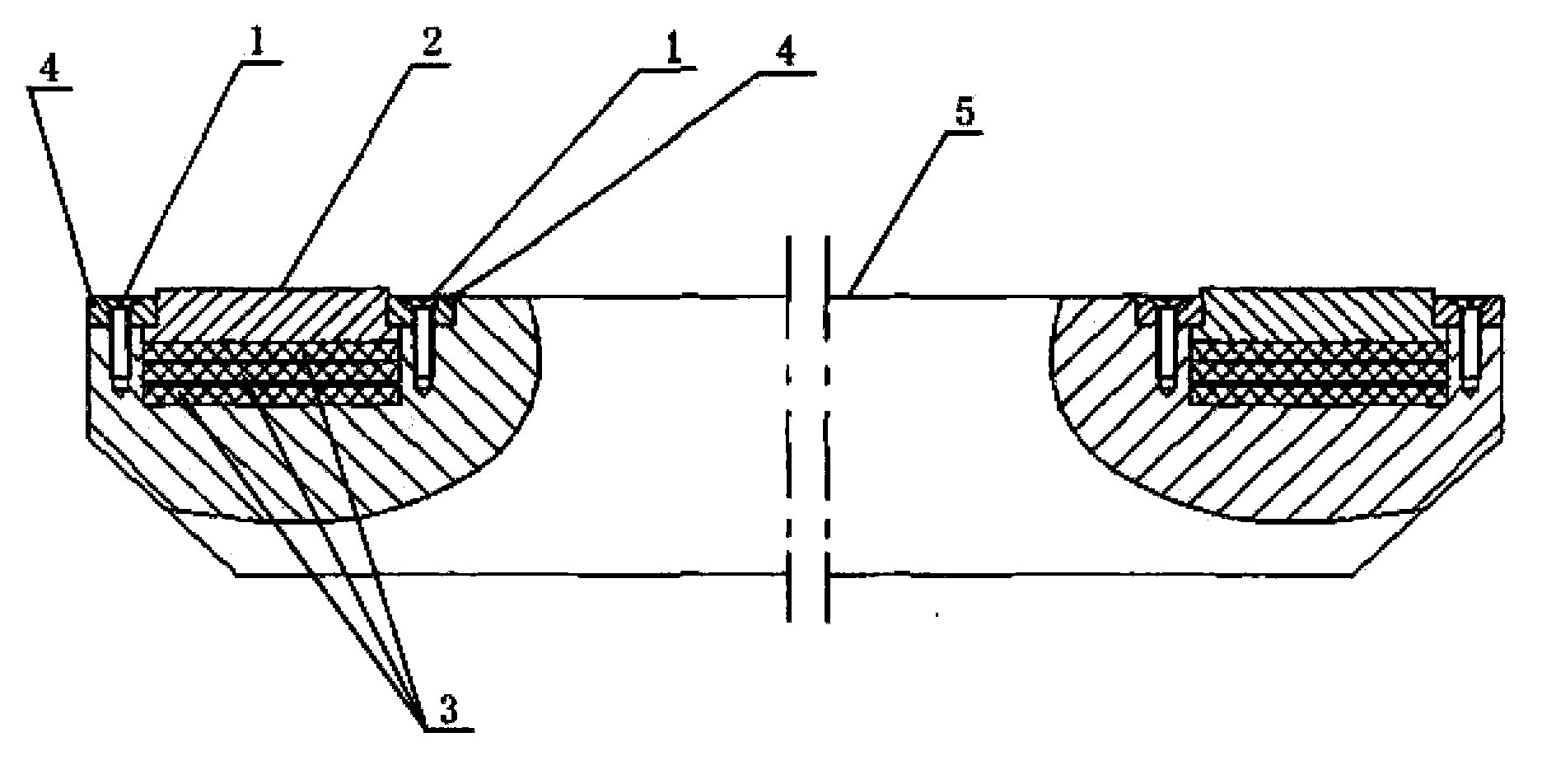

[0008] A type of horizontal punching rod structure of the press, which is composed of: screw (1), buffer block (2), elastic rubber (3), flange (4), horizontal rod (5); at both ends of the horizontal rod (5) A plurality of elastic rubbers (3) are respectively arranged under the buffer blocks (2) respectively arranged in the separately opened square holes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a horizontal hitting rod structure of a press machine. A plurality of elastic rubber blocks with a secondary buffer function are respectively arranged below buffer blocks arranged in square holes formed in the two ends of a horizontal hitting rod respectively, and flanges enable the buffer blocks to be fixed into the square holes in the two ends of the horizontal hitting rod through screws. The horizontal hitting rod structure of the press machine has the advantages that the elastic rubber blocks are respectively arranged in the square holes in the two ends of the horizontal hitting rod, due to the fact that the elastic rubber blocks have good secondary elastic buffer function, the horizontal hitting rod structure can effectively reduce noise generated when a straight hitting rod impacts the horizontal hitting rod and the buffer blocks in operation, and is simple, good in using effect and very easy to implement and popularize.

Description

Technical field [0001] The invention relates to a cross-strike bar structure, in particular to a cross-strike bar structure of a press, and belongs to the technical field of forging machinery. Background technique [0002] The function of the horizontal beater in the mechanical press is to push out the workpiece or scrap from the mold. Among them, the power for the horizontal beater comes from the impact force of the straight beater on both sides of the press rail. Because the straight beater and the horizontal beater are made of metal materials The structure, if so, the strong noise generated by the collision of the above two in work directly endangers the physical and mental health of the operators, which is easy to bring about passive work. Summary of the invention [0003] The purpose of the present invention is to provide a cross-strike bar structure of a press, which overcomes the above-mentioned shortcomings of the existing cross-strike bar structure, thereby bringing conve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21J13/14

Inventor 藏继民

Owner XUZHOU CONTENT TRANSMISSION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com