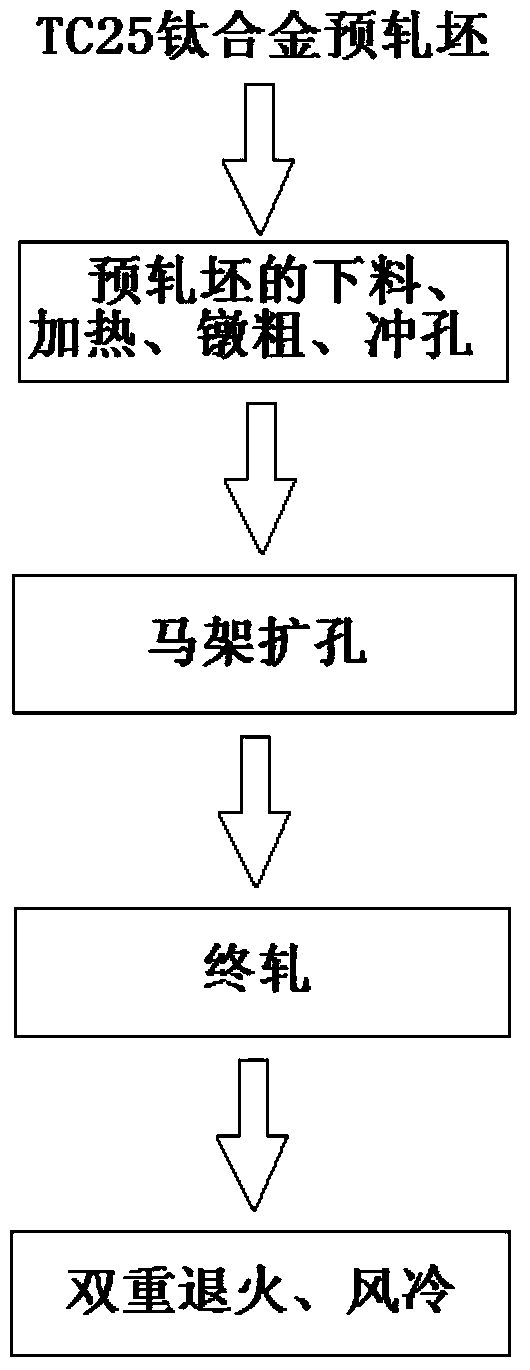

Method for manufacturing TC25 titanium alloy ring piece

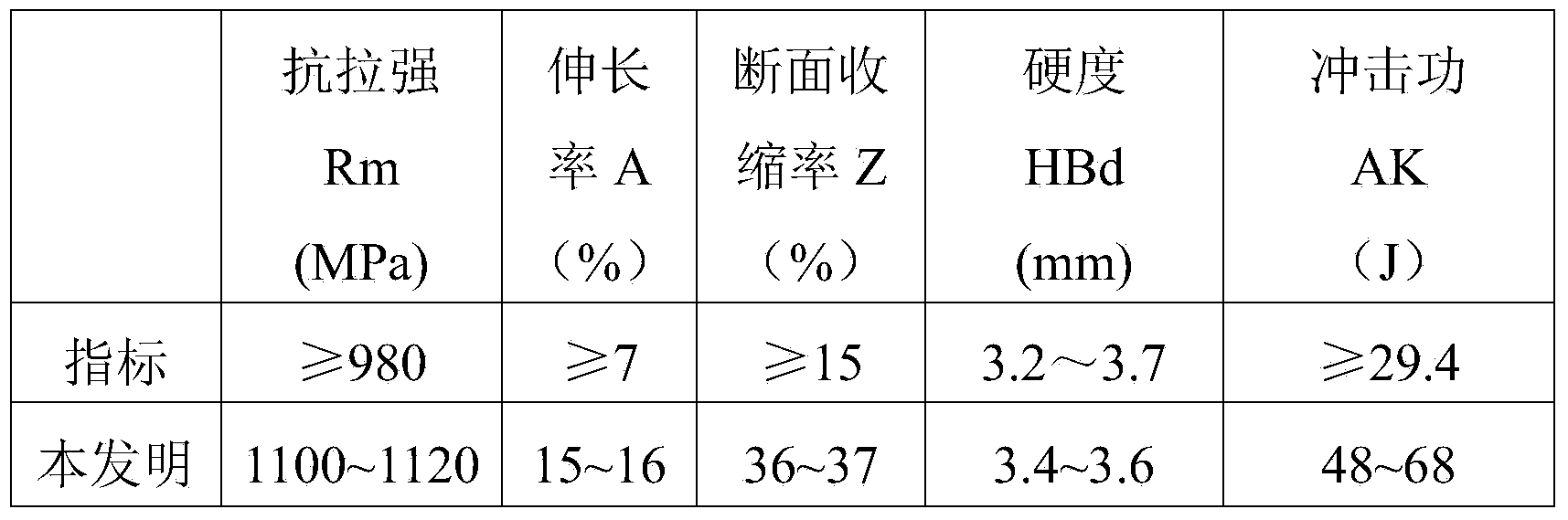

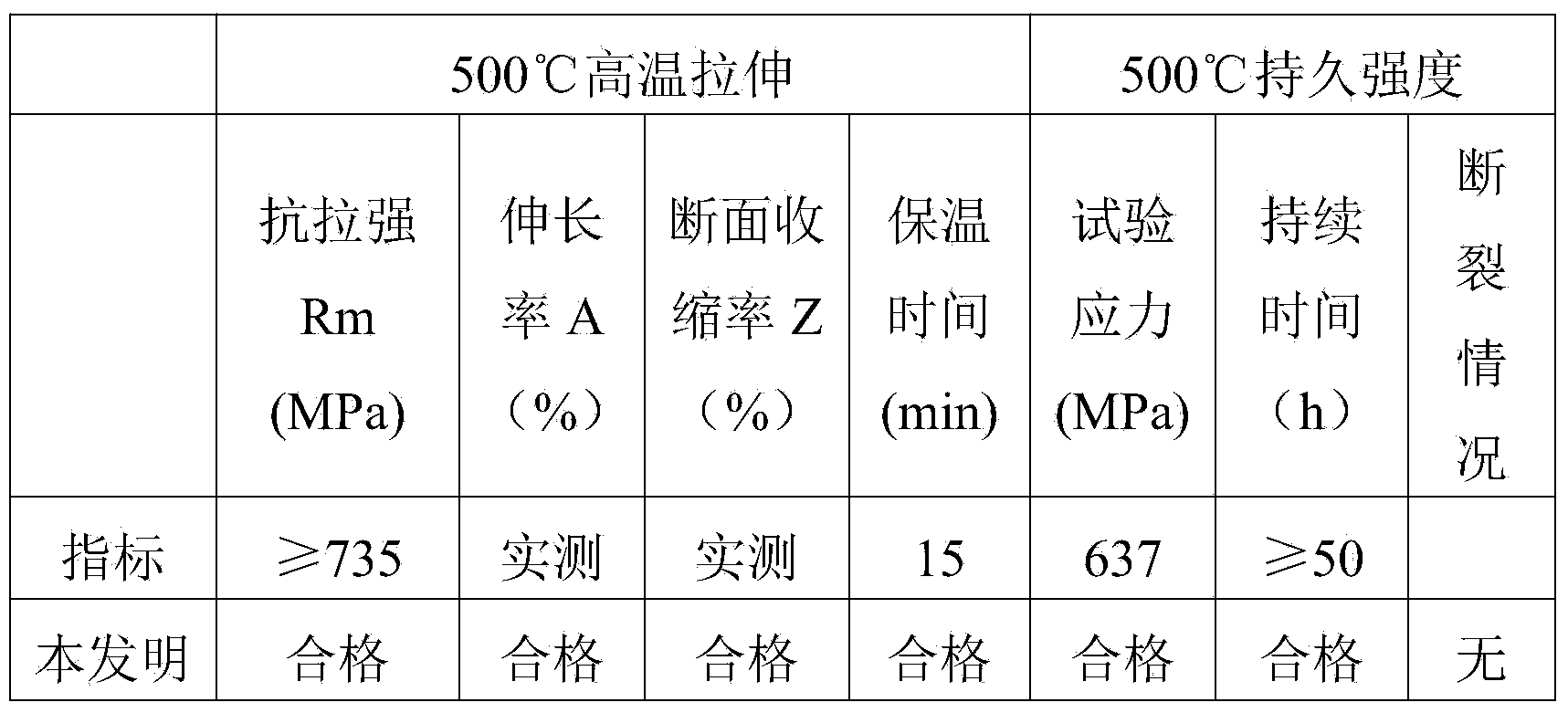

A manufacturing method, titanium alloy technology, applied in the direction of metal rolling, etc., can solve the problems of low tensile strength, 500 ℃ high tensile performance difficult to meet the standard requirements, etc., to achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Cutting, heating, upsetting and punching of pre-rolled slabs:

[0051] Heat the TC25 titanium alloy pre-rolled billet to the deformation temperature of 30°C under the phase transition point, 6min / 10mm, deform it by 50% by upsetting to obtain a solid cylinder, punch the solid cylinder so that the inner diameter of the hole is 60 of the outer diameter After %, a hollow cylinder is obtained, upsetting and punching are completed in one fire, and the final forging temperature is ≥850°C;

[0052] (2) Horse frame reaming:

[0053]Ream the hollow cylinder described in step (1) through the horse frame so that the inner diameter of the hole is 70% of the outer diameter, and the final forging temperature is ≥850°C, and return to the furnace while it is hot. time halved;

[0054] (3) Final rolling:

[0055] The forging obtained in step (2) is subjected to final rolling so that the inner diameter of the hole is 85% of the outer diameter, and the final forging temperature is ≥...

Embodiment 2

[0059] (1) Cutting, heating, upsetting and punching of pre-rolled slabs:

[0060] Heat the TC25 titanium alloy pre-rolled billet to the deformation temperature of 50°C under the phase transition point, 6min / 10mm, deform it by 60% by upsetting to obtain a solid cylinder, and punch the solid cylinder so that the inner diameter of the hole is 70% of the outer diameter After %, a hollow cylinder is obtained, upsetting and punching are completed in one fire, and the final forging temperature is ≥850°C;

[0061] (2) Horse frame reaming:

[0062] Ream the hollow cylinder described in step (1) through the horse frame so that the inner diameter of the hole is 75% of the outer diameter, and the final forging temperature is ≥850°C, and return it to the furnace while it is hot. The time is calculated according to the actual thickness at 6min / 10mm. time halved;

[0063] (3) Final rolling:

[0064] The forging obtained in step (2) is subjected to final rolling so that the inner diameter ...

Embodiment 3

[0068] (1) Cutting, heating, upsetting and punching of pre-rolled slabs:

[0069] Heat the TC25 titanium alloy pre-rolled billet to the deformation temperature of 50°C under the phase transition point, 6min / 10mm, deform it by 60% by upsetting to obtain a solid cylinder, and punch the solid cylinder so that the inner diameter of the hole is 70% of the outer diameter After %, a hollow cylinder is obtained, upsetting and punching are completed in one fire, and the final forging temperature is ≥850°C;

[0070] (2) Horse frame reaming:

[0071] Ream the hollow cylinder described in step (1) through the horse frame so that the inner diameter of the hole is 72.5% of the outer diameter, and the final forging temperature is ≥850°C, and return to the furnace while it is hot. The time is calculated as 6min / 10mm according to the actual thickness. time halved;

[0072] (3) Final rolling:

[0073] The forging obtained in step (2) is subjected to final rolling so that the inner diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com