Torque wrench used for assembling and disassembling working tips of ultrasonic medical equipment

A technology of medical equipment and working tips, which is applied in the field of force-limiting wrenches. It can solve the problems that the working tips are inserted into the inside and cannot be used and operated, and achieve the effect of firmly clamping the working tips, simple structure, and reliable protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

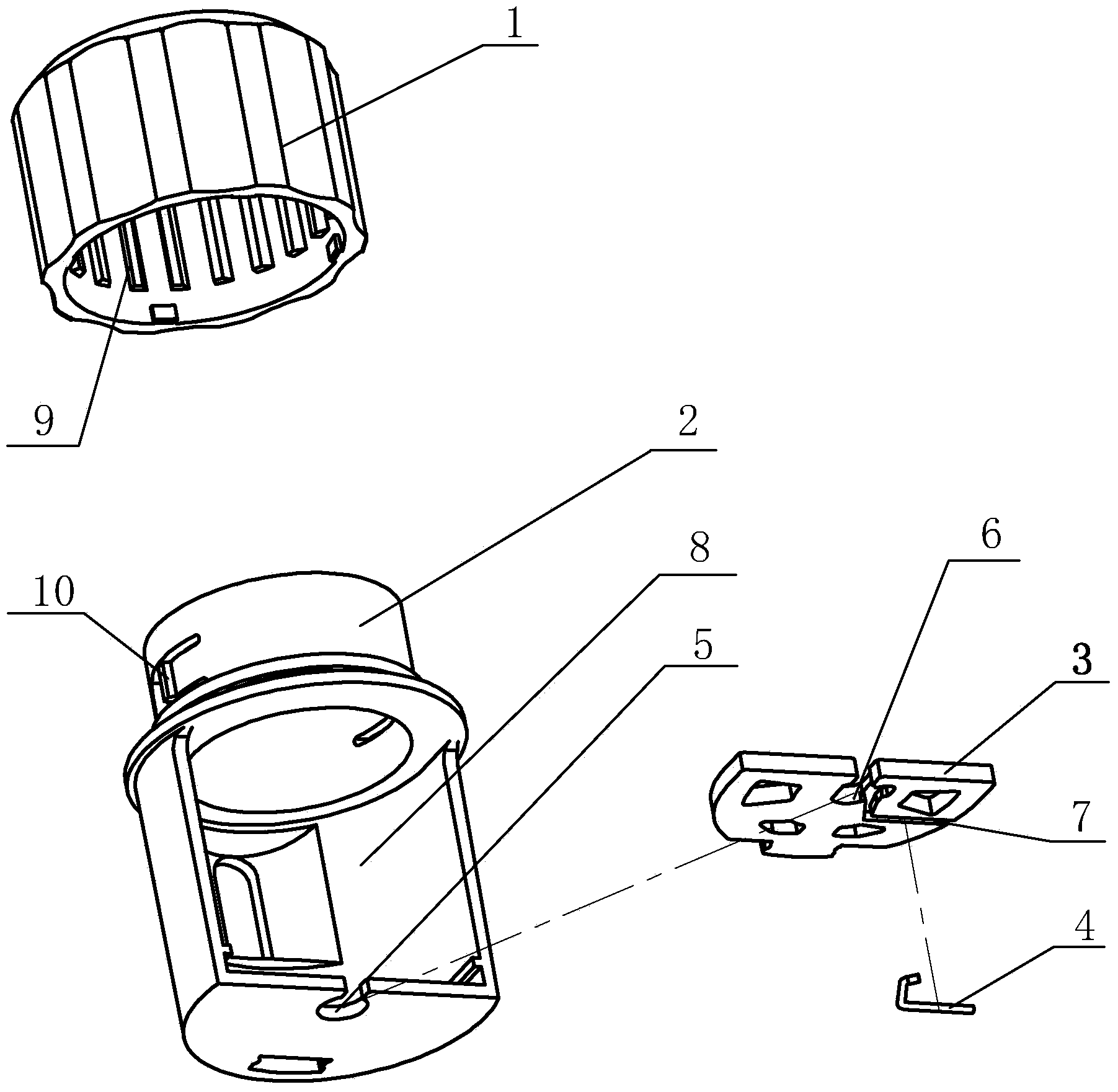

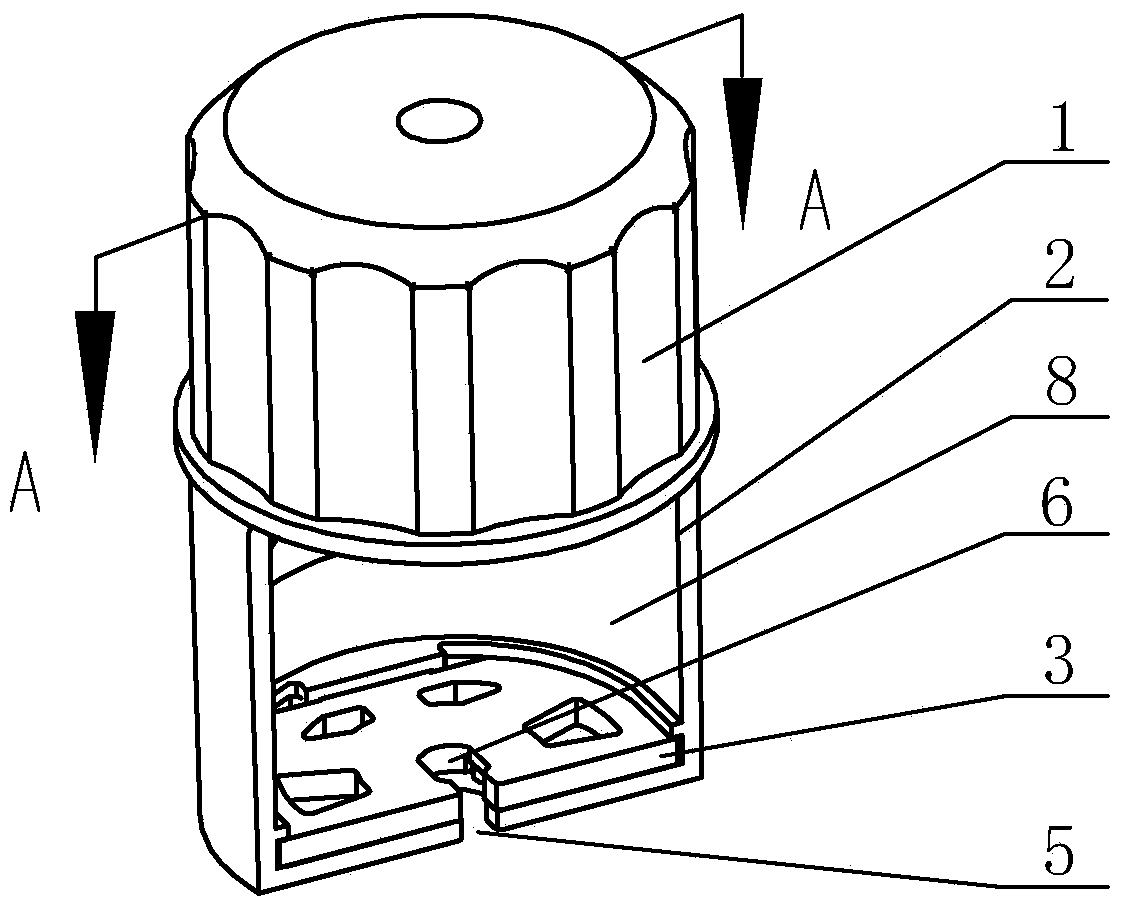

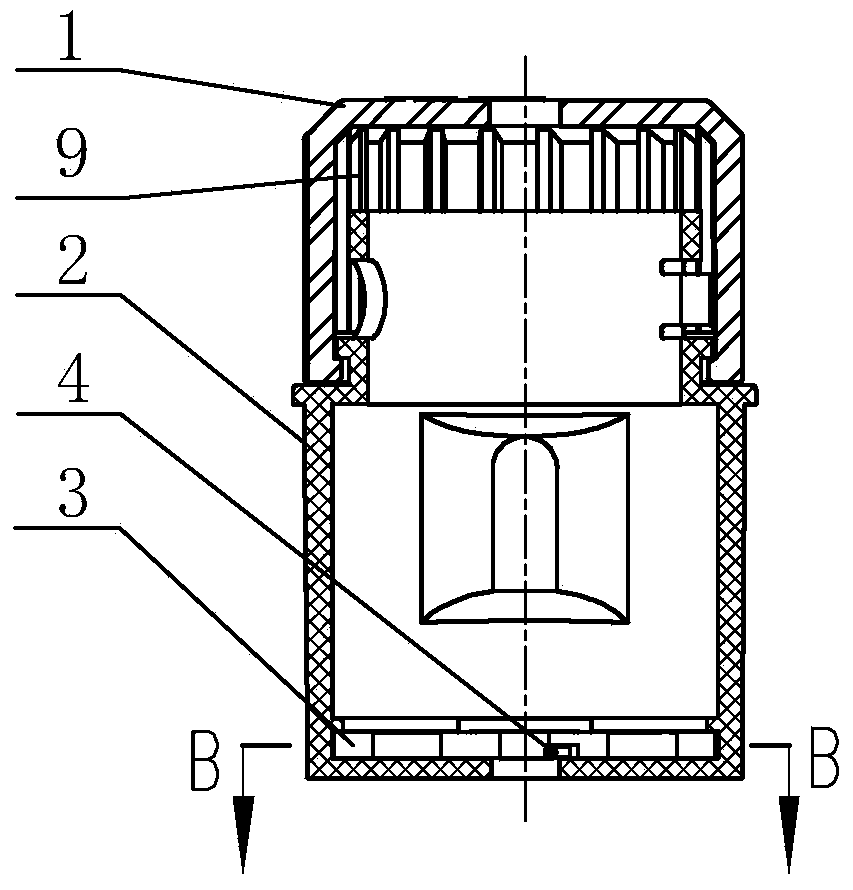

[0030] The present invention is a force limiting wrench for loading and unloading the working tip of ultrasonic medical equipment, such as figure 1 , Figure 7 As shown, it includes a wrench cover 1 and a wrench seat 2, the wrench cover 1 is a hollow columnar structure with an upper end seal, and a through hole is opened at the axis of the seal, and the wrench seat 2 is a hollow columnar structure with a lower end seal, The upper part of the wrench seat 2 is coaxially set and fixed in the wrench cover 1. A through hole is also provided at the axis of the seal of the wrench seat 2, that is, a wrench position opening 5. On the circumferential surface and the seal of the lower part of the wrench seat 2, there are holes from outside to inside. The working tip piercing groove 8 that runs through the wrench opening 5; also includes an insert 3, the insert 3 is fixed on the upper part of the seal, and a through hole is opened on the insert 3 corresponding to the wrench opening 5, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com