Workpiece auto-carry device

An automatic and carrying technology, applied in the field of manipulators, can solve the problems of low processing efficiency, offset of connecting parts, complex structure, etc., and achieve the effect of less floor space, stable and accurate force transmission process, and large working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

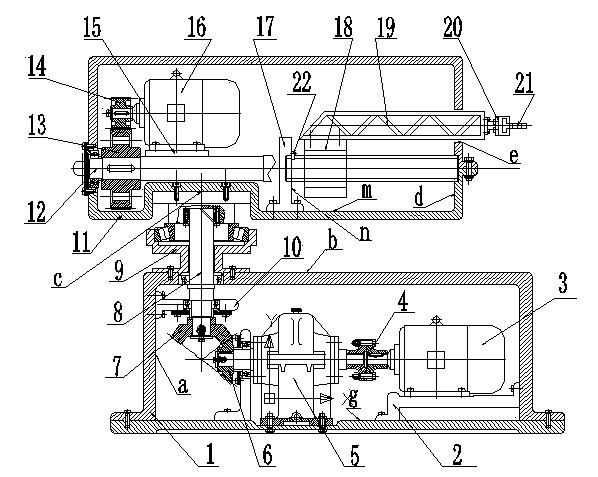

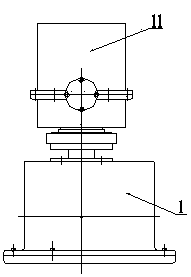

[0017] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

[0018] Such as Figure 1-2 As shown, the device can achieve a maximum grasping weight of 150kg, a maximum moving speed of 2m / s, an arm telescopic stroke of 200mm, a maximum working radius of 800mm, and an arm swing angle of 90°. The automatic workpiece loading device includes a box (1), one motor support plate (2), one three-phase asynchronous motor (3), flange coupling (4), reducer (5), small bevel gear (6), large bevel gear (7), Rotary shaft (8), support frame (9), support plate one (10), box body two (11), lead screw (12), large spur gear (13), small spur gear (14), motor support plate two (15), three-phase asynchronous motor two (16), support plate two (17), horizontal screw sleeve (18), truss (19), hand claw (21), cylinder (20), baffle plate (22), three The output shaft of phase asynchronous motor one (3) is connected with the input shaft of the reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com