Novel high-efficiency bag supply system

A high-efficiency, bag-feeding technology, applied in packaging and other directions, can solve the problems of low efficiency of the bag-feeding system, achieve the effects of improving the bag-feeding success rate, reducing regularity requirements, and alleviating work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

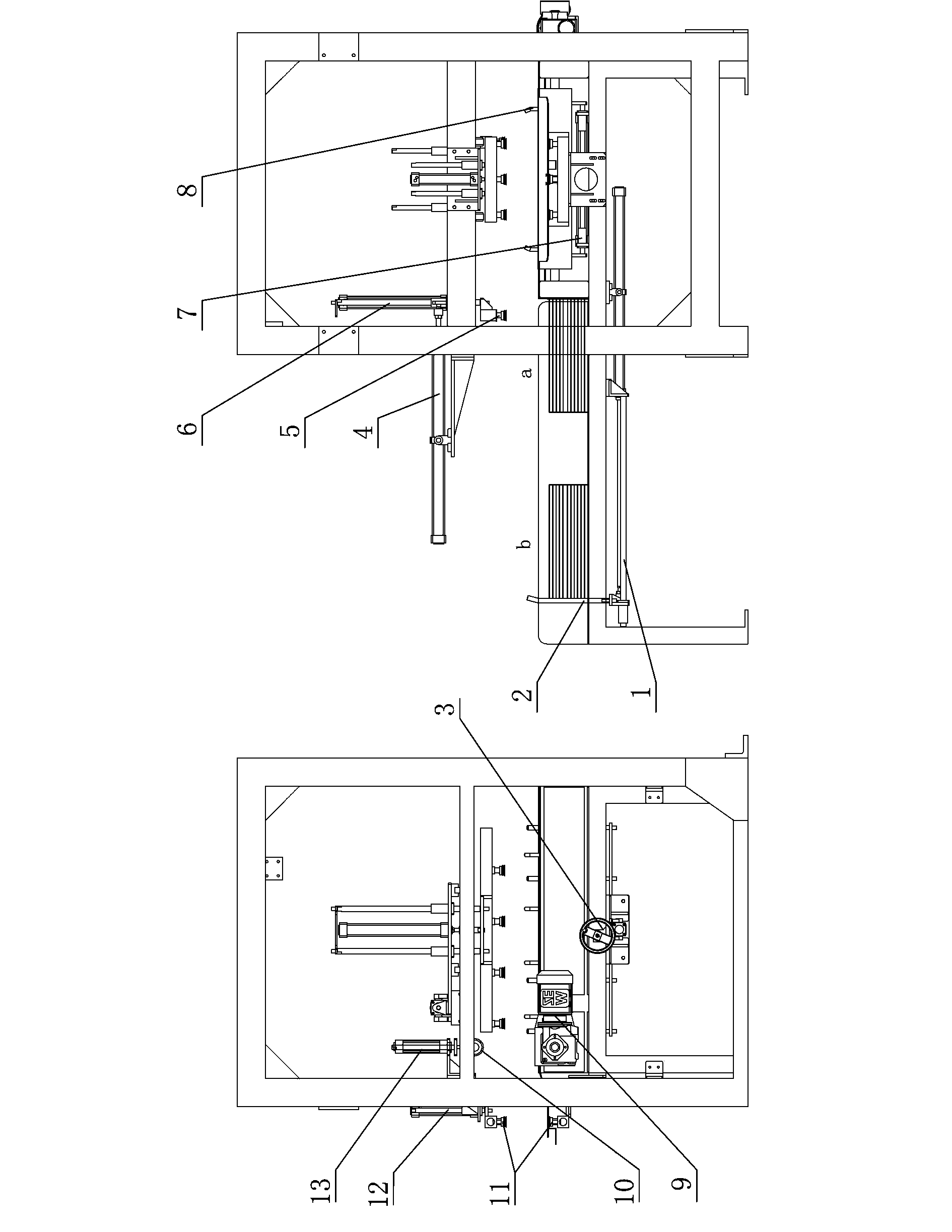

[0015] see figure 1 , as shown in the figure, this system mainly includes two parts: bag preparation system, bag fetching, bag delivery, and pre-opening system.

[0016] 1) Bag preparation system:

[0017] The bag preparation system plays the role of bag supply and consists of bag supply station a and buffer bag release station b. The bag preparation system also includes a bag push cylinder 1 and a bag push rod 2 .

[0018] During the first operation, both the bag feeding station and the bag taking station need to manually place neatly stacked packaging bags; when there is no bag at the bag feeding station, the photoelectric switch for bag preparation sends out a signal, and the bag pushing cylinder 1 acts to release the cache The bag at the bag station b is sent to the bag supply station a. When the photoelectric sensor of the bag is detected again, the bag is pushed and the cylinder 1 is reset. Afterwards, there is no bag at the buffer bag releasing station b, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com