Material adjusting conveying device for laser engraving machine

A transmission device and laser engraving machine technology, which is applied in the field of material adjustment transmission device for laser engraving machines, can solve the problems of pallet detaching from the conveyor belt, product troubles, pattern deviation, etc., and achieve the effect of stable pallet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

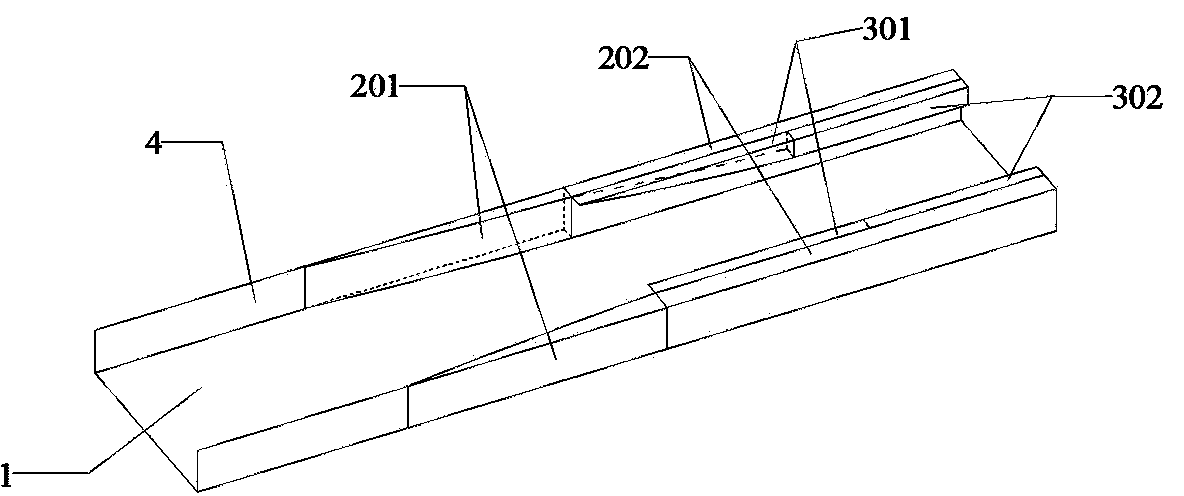

[0018] A material adjustment conveying device for a laser engraving machine, comprising a conveyor belt 1, a tray, a baffle plate 4, a width adjustment plate and a height adjustment plate respectively located on both sides of the conveyor belt 1 from outside to inside; the tray is a rectangular tray;

[0019] Width adjustment plate comprises first width adjustment plate 201 and second width adjustment plate 202; The face is a right triangle with a vertex angle ranging from 0 to 5 degrees.

[0020] The height adjustment plate comprises a first height adjustment plate 301 and a second height adjustment plate 302; the first height adjustment plate 301 is a triangular straight cylinder, the second height adjustment plate 302 is a cuboid, and the first height adjustment plate 301 and the second width adjustment The contact surface of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com