Fish meat floss frying machine

A fish frying machine and frame technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of affecting the processing quality, inconvenient loading of raw materials and taking out finished products, burnt and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

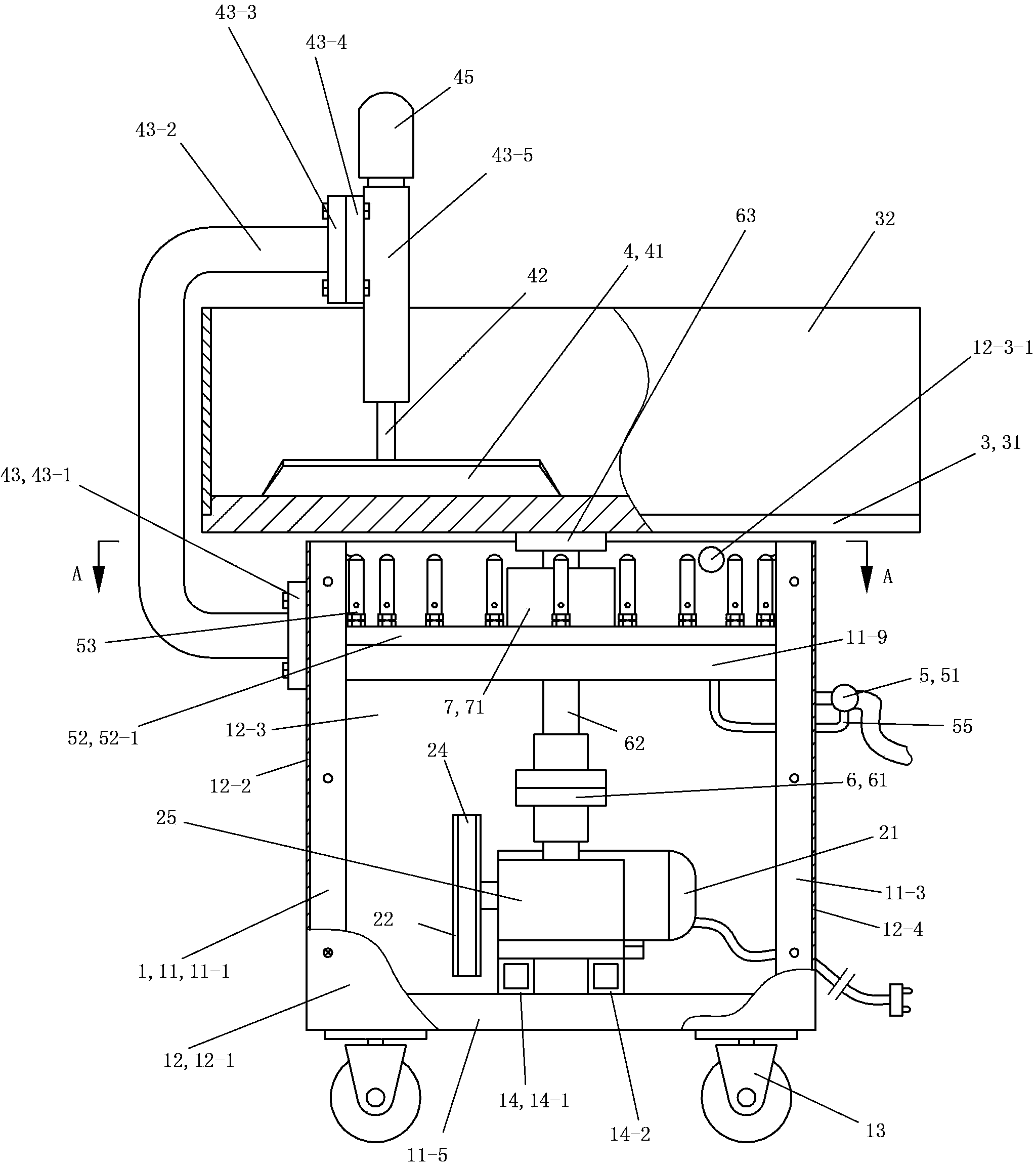

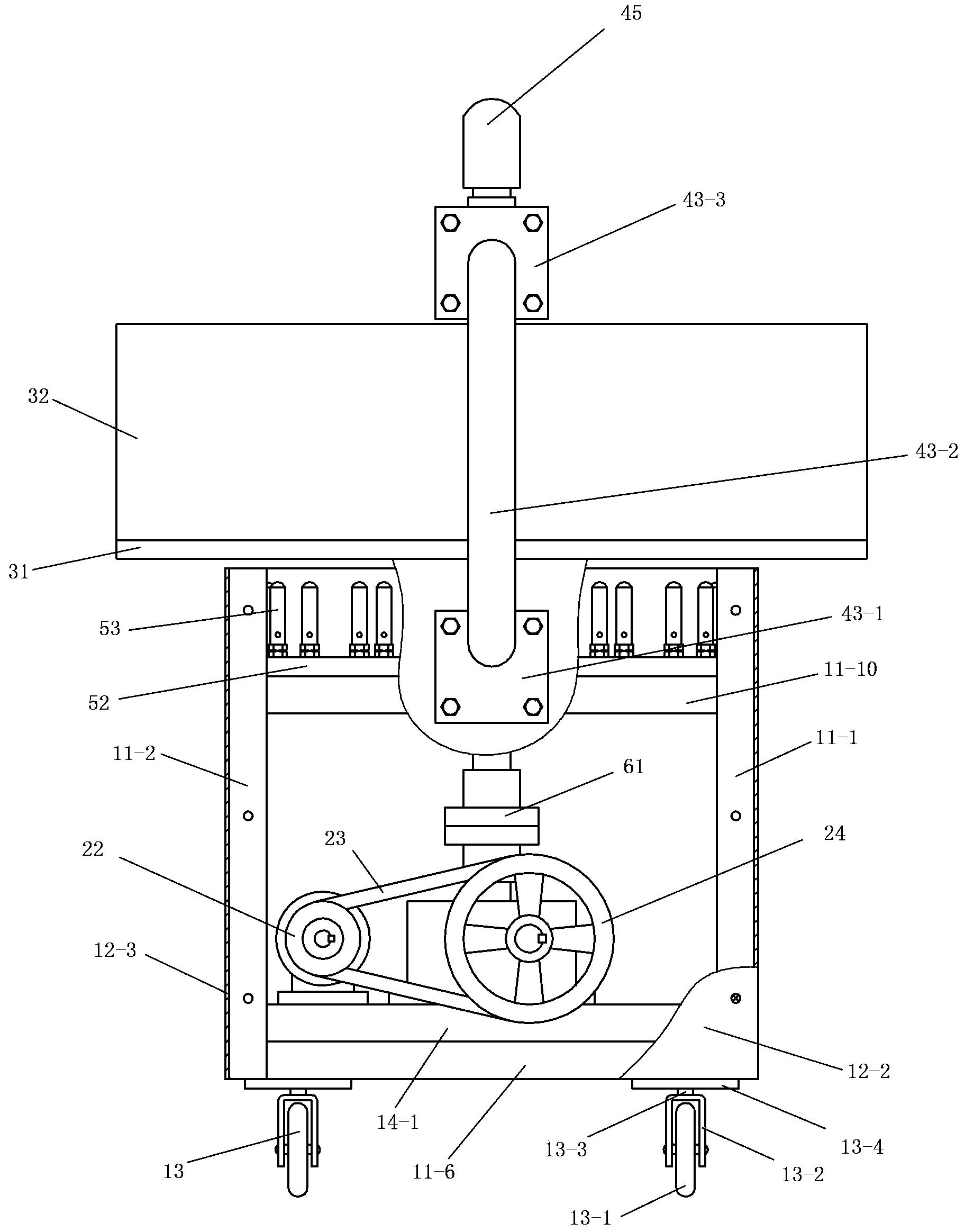

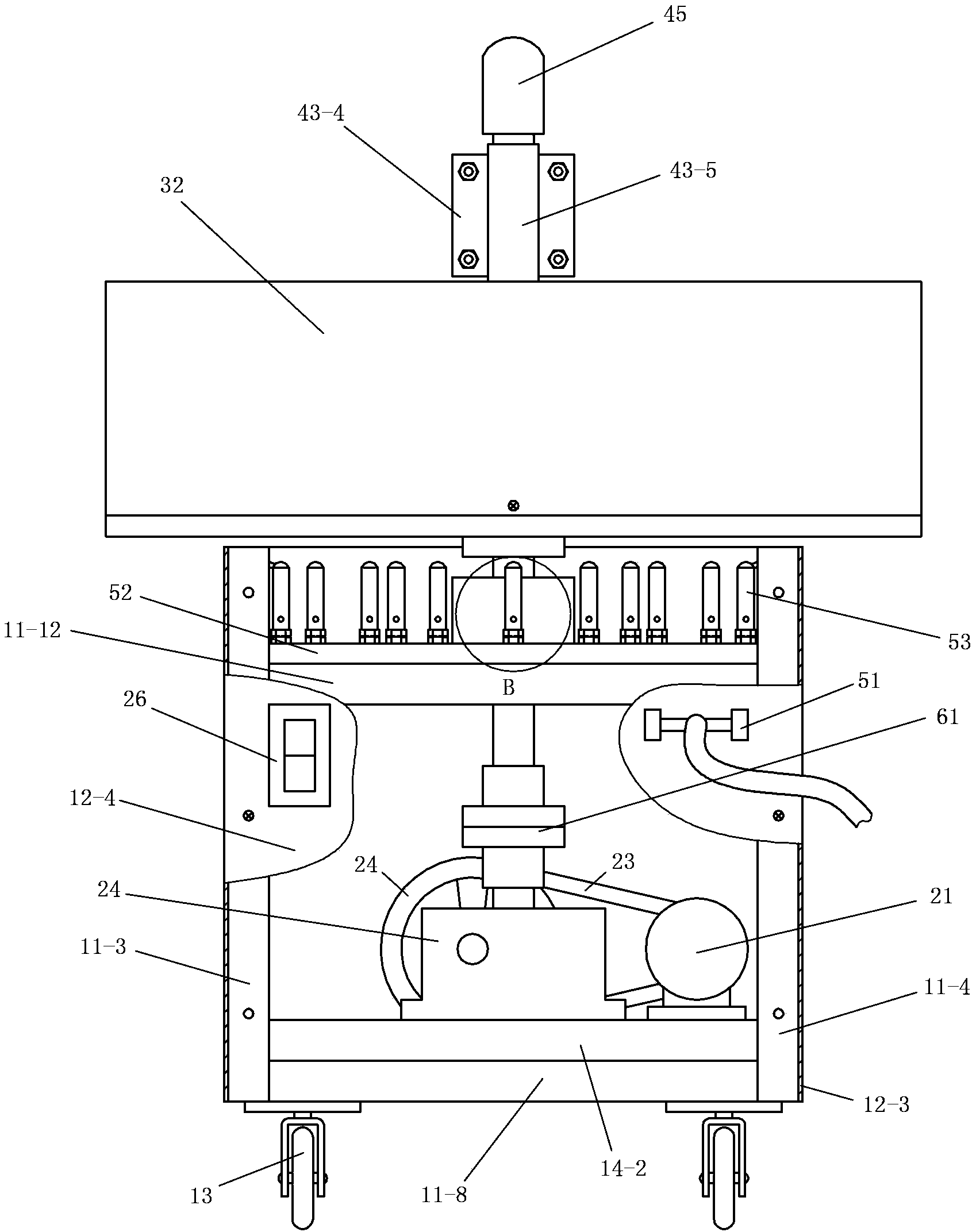

[0062] See figure 1 , The fish frying machine of this embodiment is mainly composed of a chassis 1, a driving device, a frying pan 3, a stir frying device 4, a burner 5, a connecting assembly 6 and a bearing assembly 7.

[0063] See Figure 1 to Figure 3 , Figure 7 and Figure 9 , Cabinet 1 is mainly made up of frame, guard plate 12 and caster 13. Frame is made up of frame main body 11, lower frame body 14 and upper frame body 15. The frame main body 11 mainly consists of the left front vertical beam 11-1, the left rear vertical beam 11-2, the right front vertical beam 11-3, the right rear vertical beam 11-4, the front lower cross beam 11-5, Left lower longitudinal beam 11-6, rear lower longitudinal beam 11-7, right lower longitudinal beam 11-8, front upper longitudinal beam 11-9, left upper longitudinal beam 11-10, rear upper transverse beam 11-11 and right upper longitudinal beam 11-12 . Left front vertical beam 11-1, left rear vertical beam 11-2, right front vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com