Automatic splicing and active deviation rectifying system of wirecord fabric cutting machine

An automatic splicing, steel cord technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of dislocation, interference, and tail deviation of the cord, so as to improve the pass rate, reduce the intensity and difficulty of operation, and realize intelligent The effect of identifying and proactively correcting deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

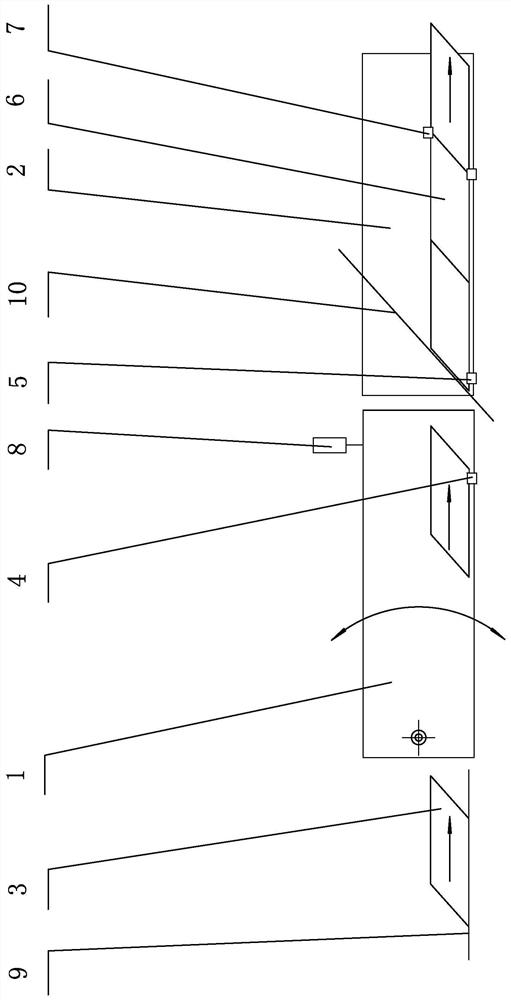

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0019] The automatic splicing and active deviation correction system of the steel cord cutting machine of the present invention includes a deviation correction splicing device, and the deviation correction splicing device includes a joint splicing machine 2 arranged in front along the cord conveying direction and a joint feeder 1 arranged behind, and the joint feeder The rear end of feeder 1 is hinged, and the left side of the front part of joint feeder 1 is provided with a servo-driven electric push rod 8. The electric push rod 8 is hinged, and the electric push rod 8 is a telescopic rod extending horizontally to the right. Hinged to the joint feeder 1, the telescopic movement of the telescopic rod drives the joint feeder 1 to swing around the hinged center of the rear end, so that the front outlet of the joint feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com