Sand removal engineering truck

A technology for engineering vehicles and vehicle bodies, applied in track cleaning, construction, cleaning methods, etc., can solve the problem of lack of sand cleaning function in construction machinery, etc., and achieve the effect of strong continuous working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

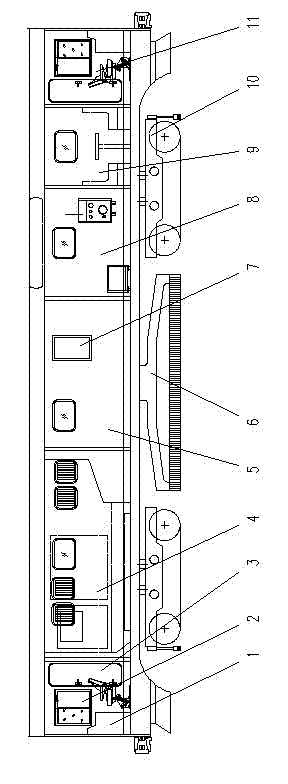

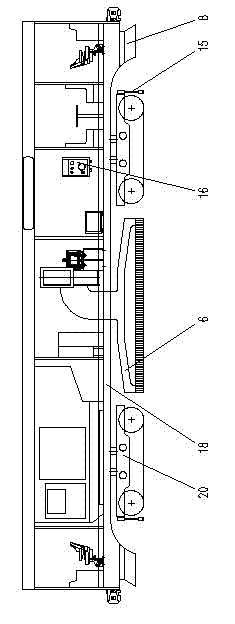

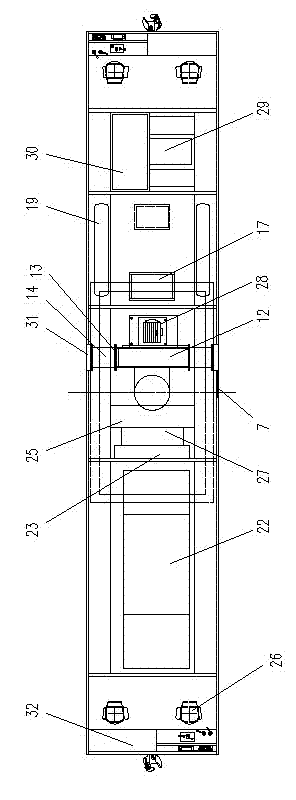

[0018] An embodiment of the present invention, such as figure 1 As shown, a sand removal engineering vehicle, its body frame is divided into upper and lower parts.

[0019] Both ends of the lower part are bogies 20, and the middle part is a sand suction device 6. The upper part is followed by driver's cab I1, power room 4, working room 5, auxiliary room 8, living room 9 and driver's cab II11.

[0020] Wherein, the working chamber 5 and the sand suction device 6 are the key points of the present invention.

[0021] Sand throwing machine 12 is positioned at working room 5, and sand throwing machine 12 is arranged on the center line of engineering vehicle, and its both sides are provided with air outlet 13, and the sand throwing movable air duct 14 that can be appointed on the air outlet 13 is equipped with, connects lift. As for the sand device 31, the side wall of the working chamber 5 is provided with a movable damper 7 for closing the air outlet 13. In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com