Pipeline leakage test set and method

An experimental device and pipeline leakage technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of low accuracy such as the range of influence of flammable and explosive gas diffusion, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

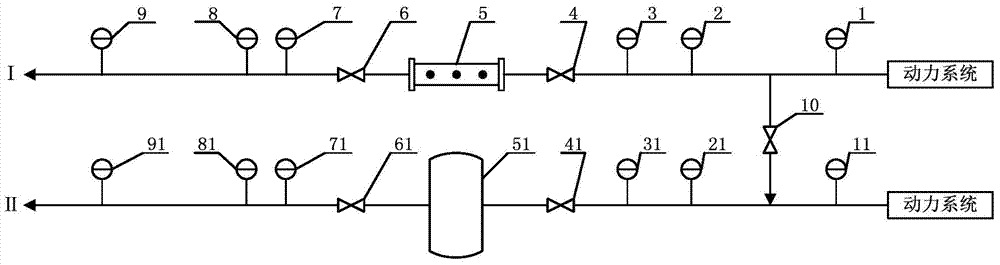

[0034] refer to figure 1 , the pipeline leakage test device I of the present invention is composed of a power system, a leakage unit, a valve, a thermometer, a volume flow meter and a pressure gauge. The power system is connected to the leakage unit through a pipeline. Meter 1, volume flow meter 9, pressure gauge 2, pressure gauge 8, thermometer 3, thermometer 7.

[0035] refer to figure 1 In the present invention, the pipeline leakage test device I and test device II are connected in parallel with the valve 10 through the feeding branch pipe, and the two ends of the leakage unit are respectively connected with the valve 41, the valve 61, the volume flow meter 1, the volume flow meter 11, the volume flow meter 91, and the pressure gauge 21, pressure gauge 81, thermometer 31, thermometer 71.

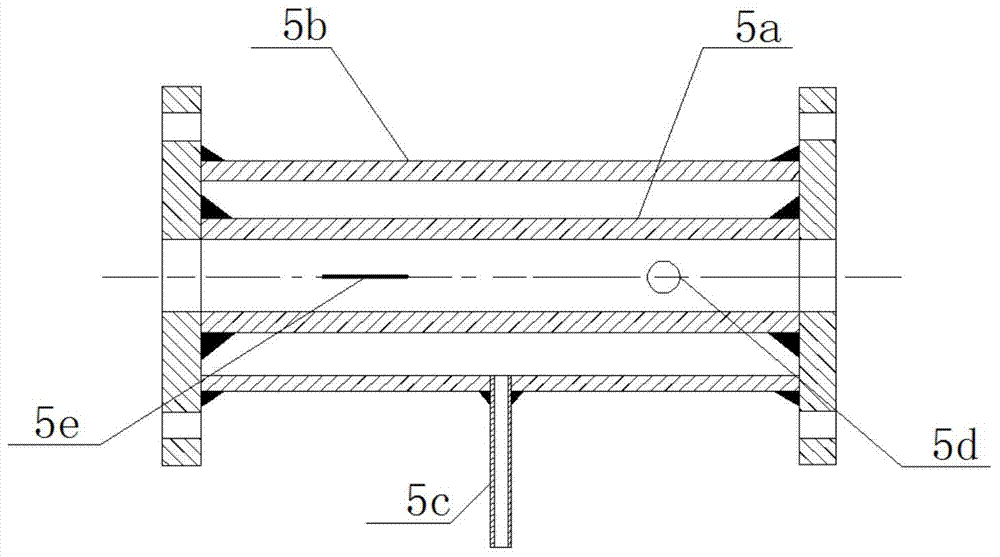

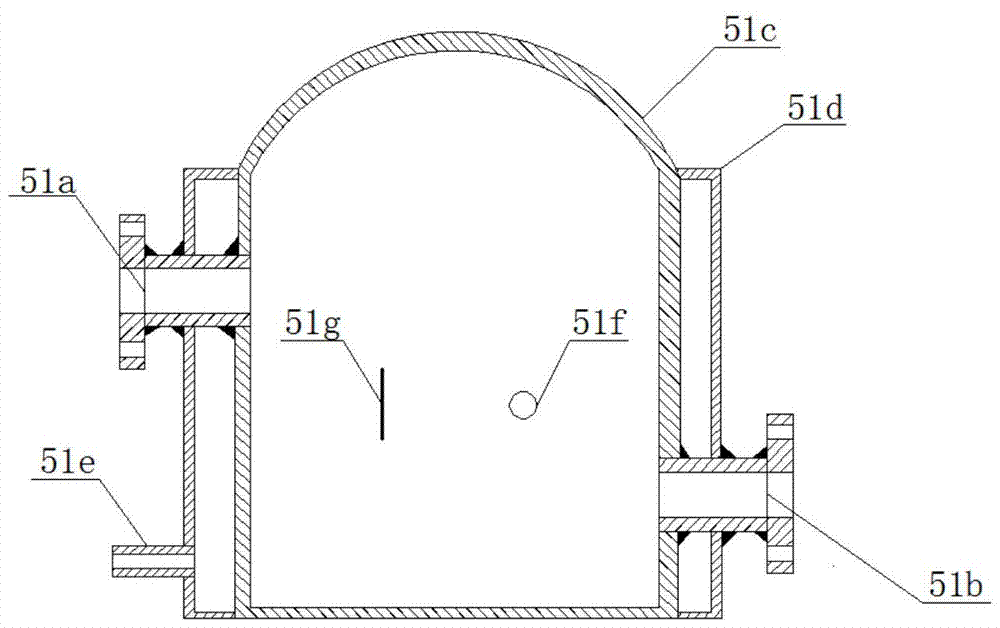

[0036] The leakage unit is the pipeline leakage unit 5 or the storage tank leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com