Patents

Literature

41results about How to "Fast metering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

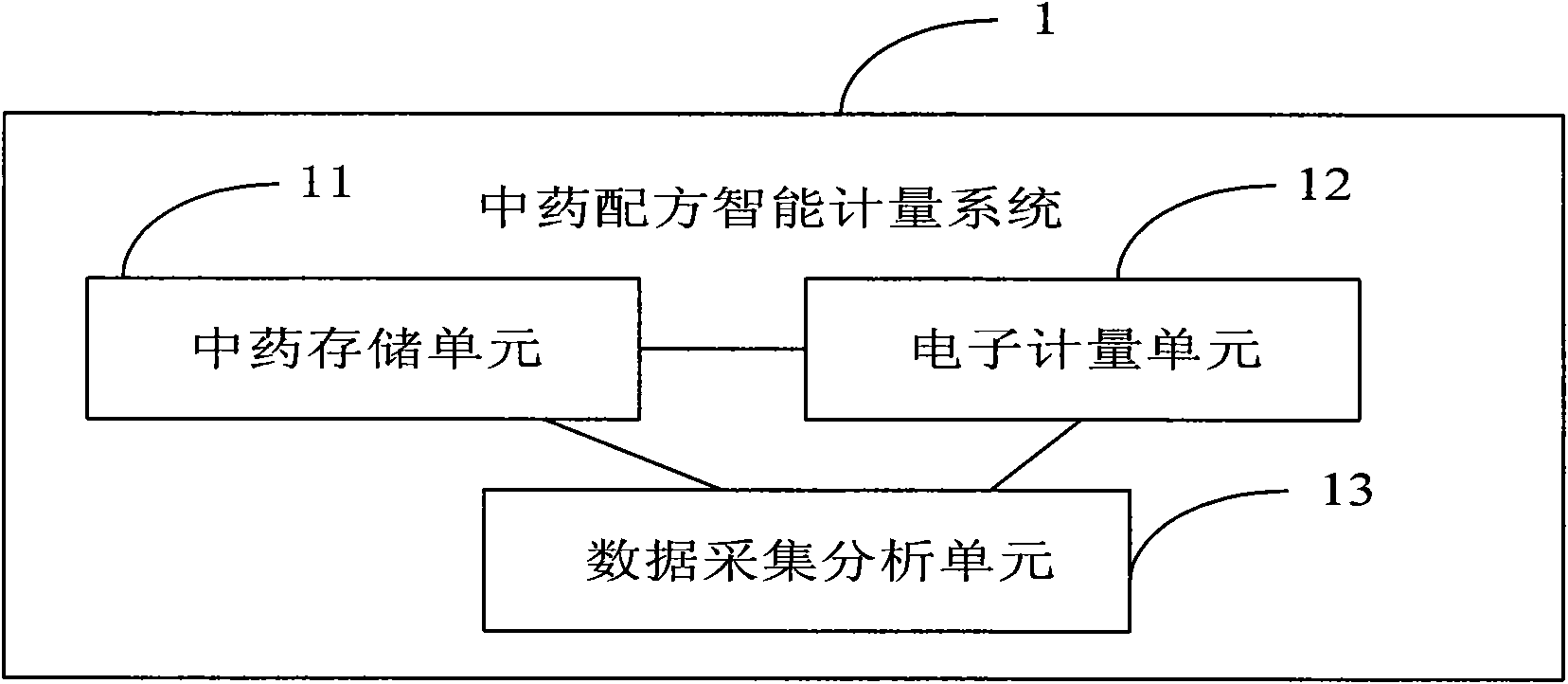

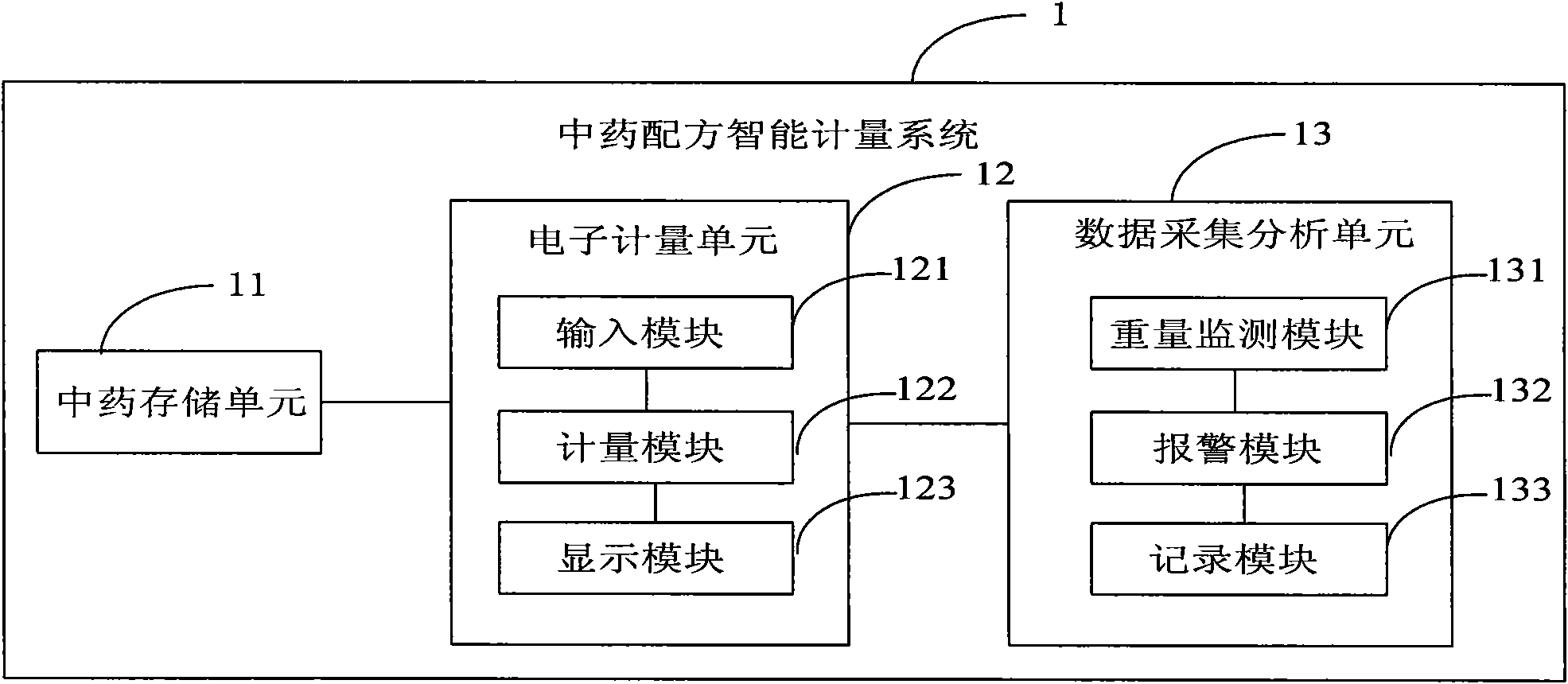

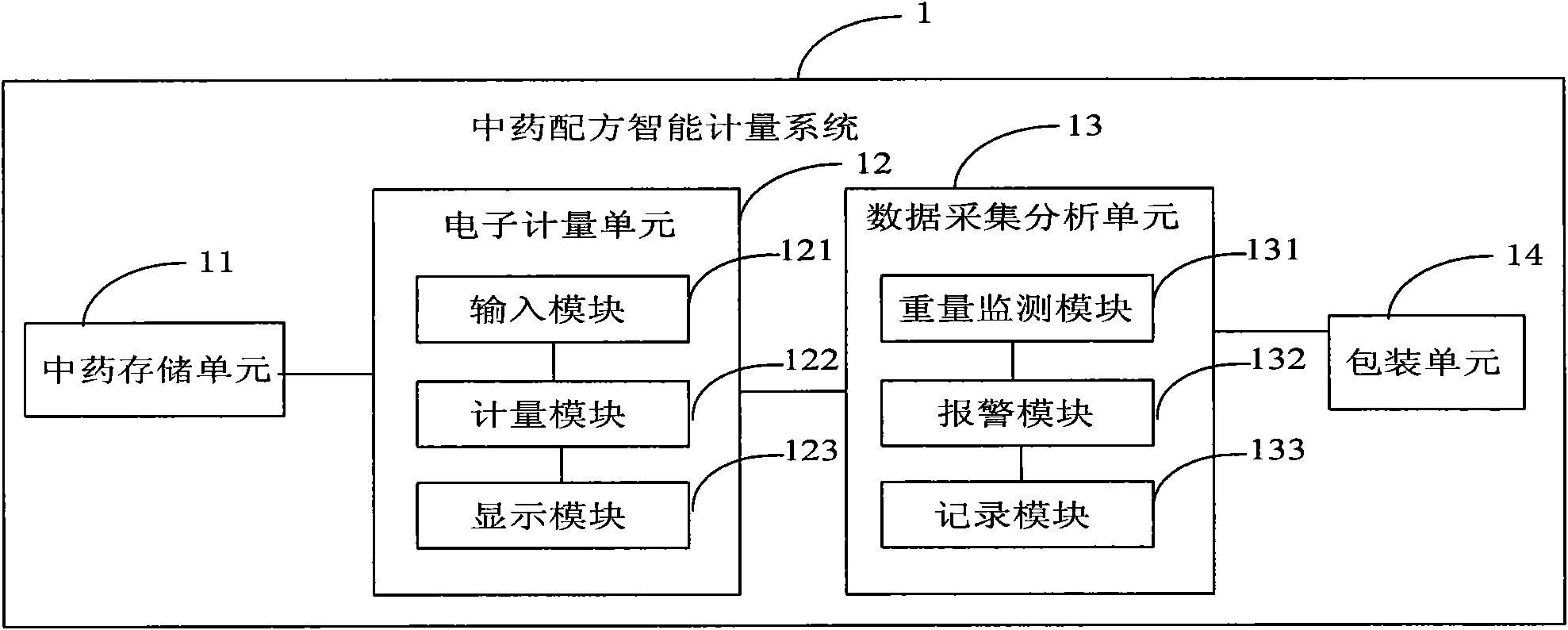

Chinese medicament formula intelligent measuring system

InactiveCN101839755AFast meteringAccurate measurementSolid materialSpecial purpose weighing apparatusMedicineData acquisition

The invention discloses a Chinese medicament formula intelligent measuring system, which is used for measuring the Chinese medicinal materials in a Chinese medicament formula. The system comprises a Chinese medicament storage unit, an electronic measuring unit and a data collection and analysis unit, wherein the Chinese medicament storage unit is used for storing various Chinese medicinal materials; the electronic measuring unit is used for measuring the various Chinese medicinal materials which are stored in the Chinese medicament storage unit and correspond to the Chinese medicament formula according to the Chinese medicament formula input by a user; and the data collection and analysis unit is used for monitoring the weighs, measured by the electronic measuring unit, of the various Chinese medicinal materials and recording the information on each time of measurement of the Chinese medicament formula intelligent measuring system. Thus, the Chinese medicament formula intelligent measuring system provided by the invention realizes accurate and quick measurement of the various Chinese medicinal materials of the Chinese medicament formula.

Owner:SICHUAN NEAUTUS TRADITIONAL CHINESE MEDICINE

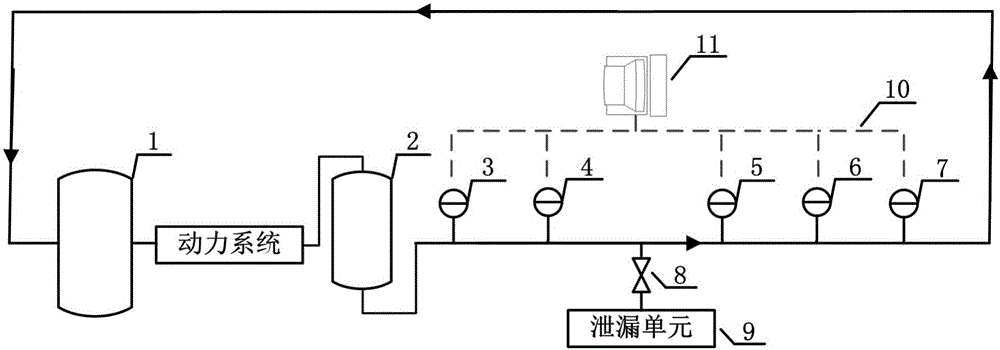

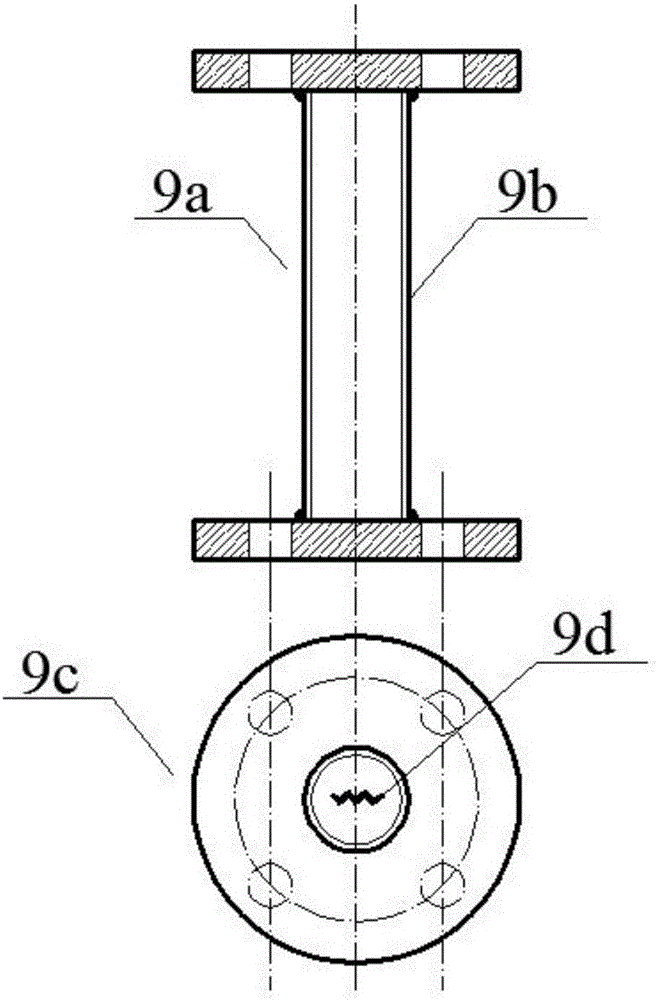

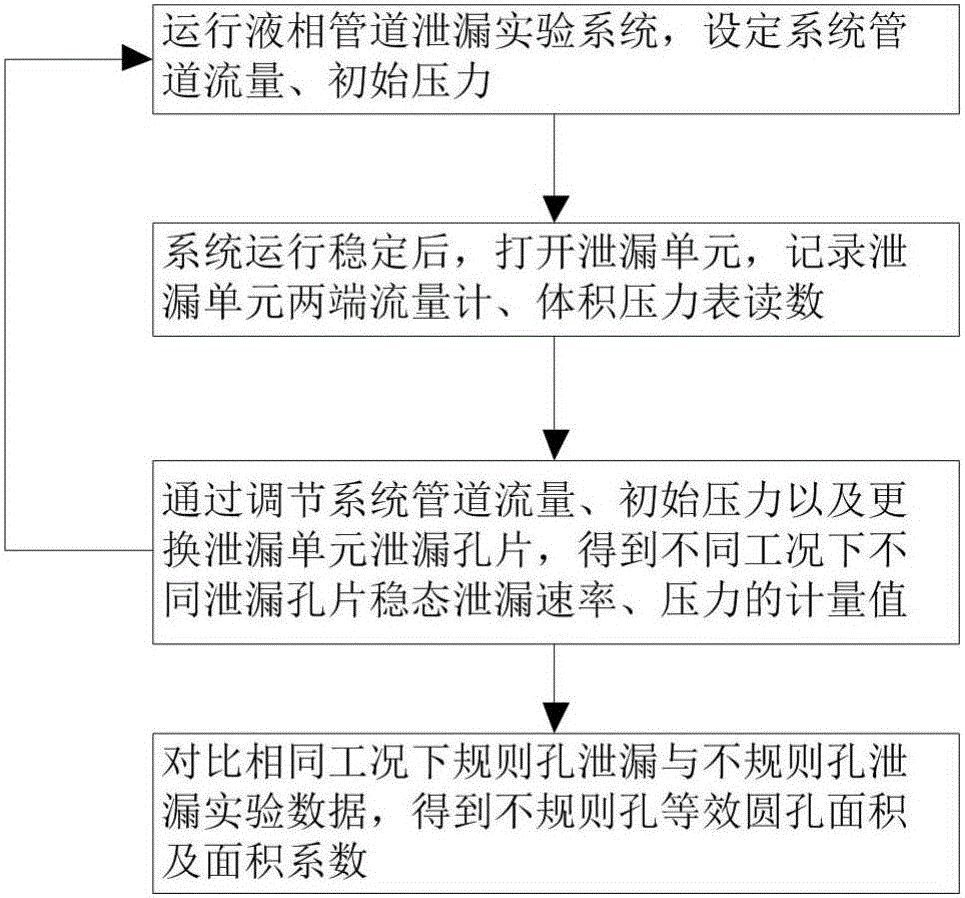

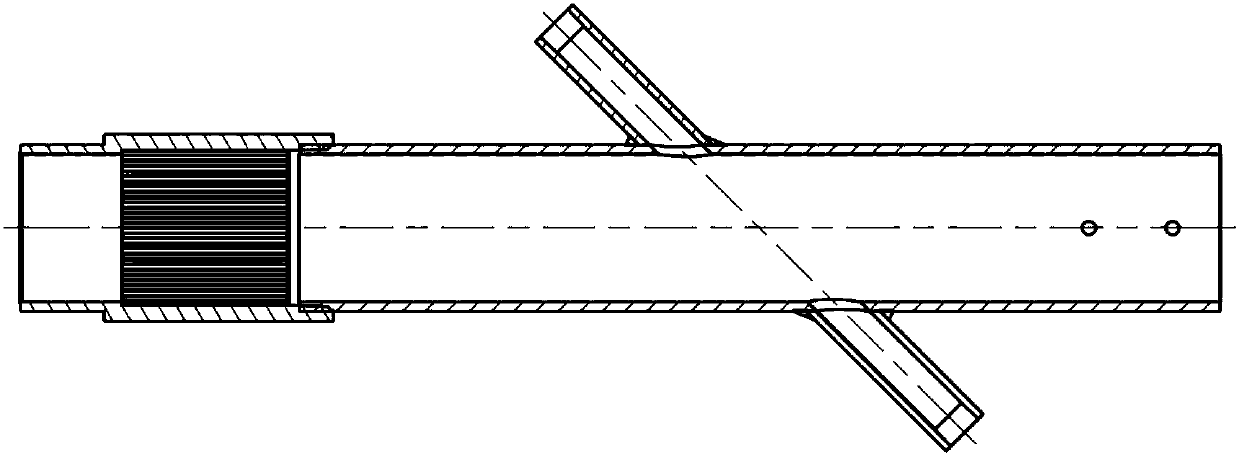

Liquid-phase pipe leakage irregular hole equivalent round hole experimental device and experimental method

The invention relates to a liquid-phase pipe leakage irregular hole equivalent round hole experimental device and an experimental method; the device and the method can research stable and dynamic leakage characteristics and rules of regular holes and irregular holes of liquid-phase pipes under various different leakage working conditions, simulate aerial, underground and underwater real leakage processes, calculate equivalent round hole areas and area coefficients of the irregular holes, realize real-time, accurate and quick metering of the leakage speed, obtain evolvement rules of such parameters as pressure and flow along with the leakage process, and are used for quickly calculating the leakage speed and predicting and estimating the leakage influence range. The device and the method can perform similar experiments of multiple different leakage working conditions indoors, facilitate accurate prediction of the pipe leakage speed and the leakage diffusion influence range, and provide theoretical basis for daily safety maintenance of long transmission pipes and emergency rescue and accident investigation of leakage accidents.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

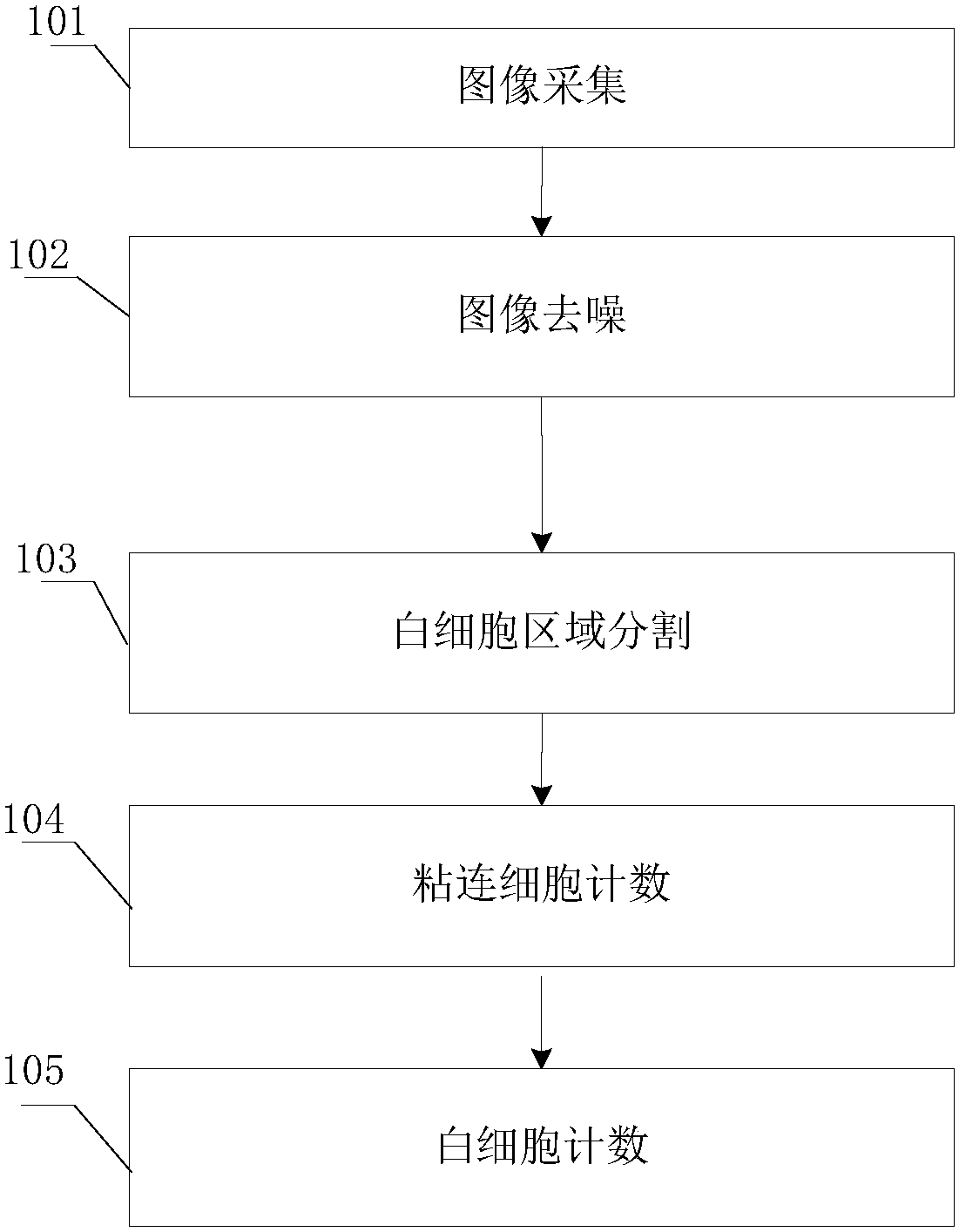

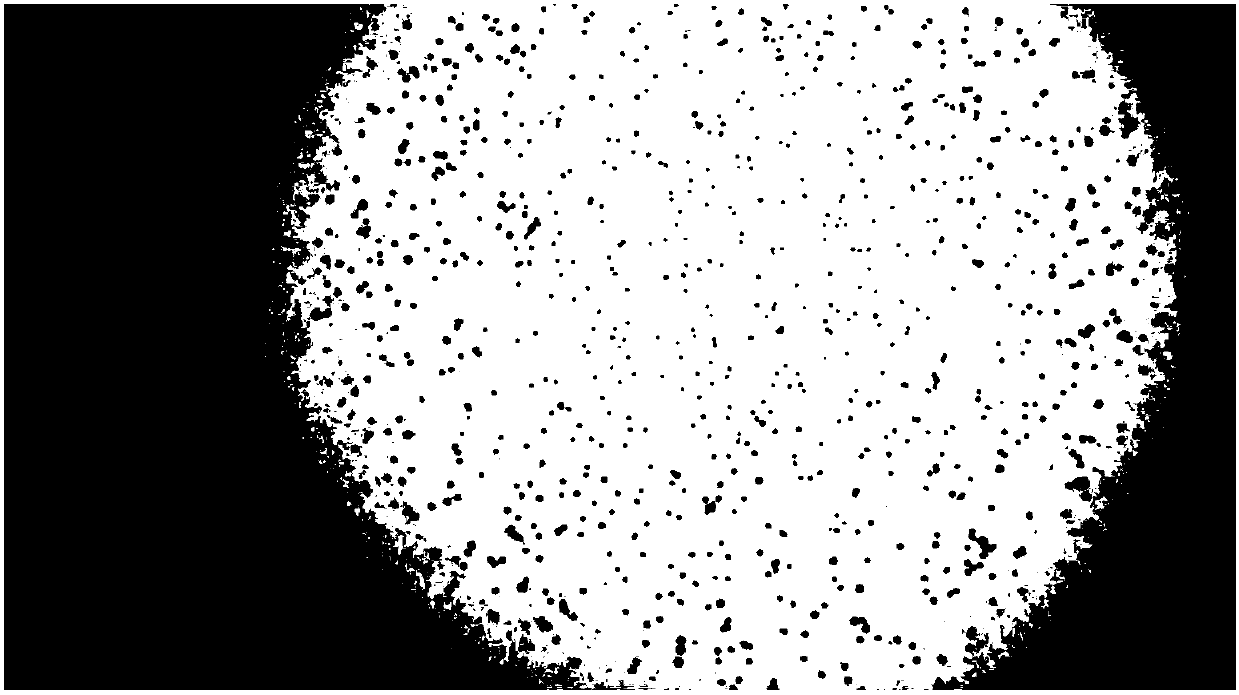

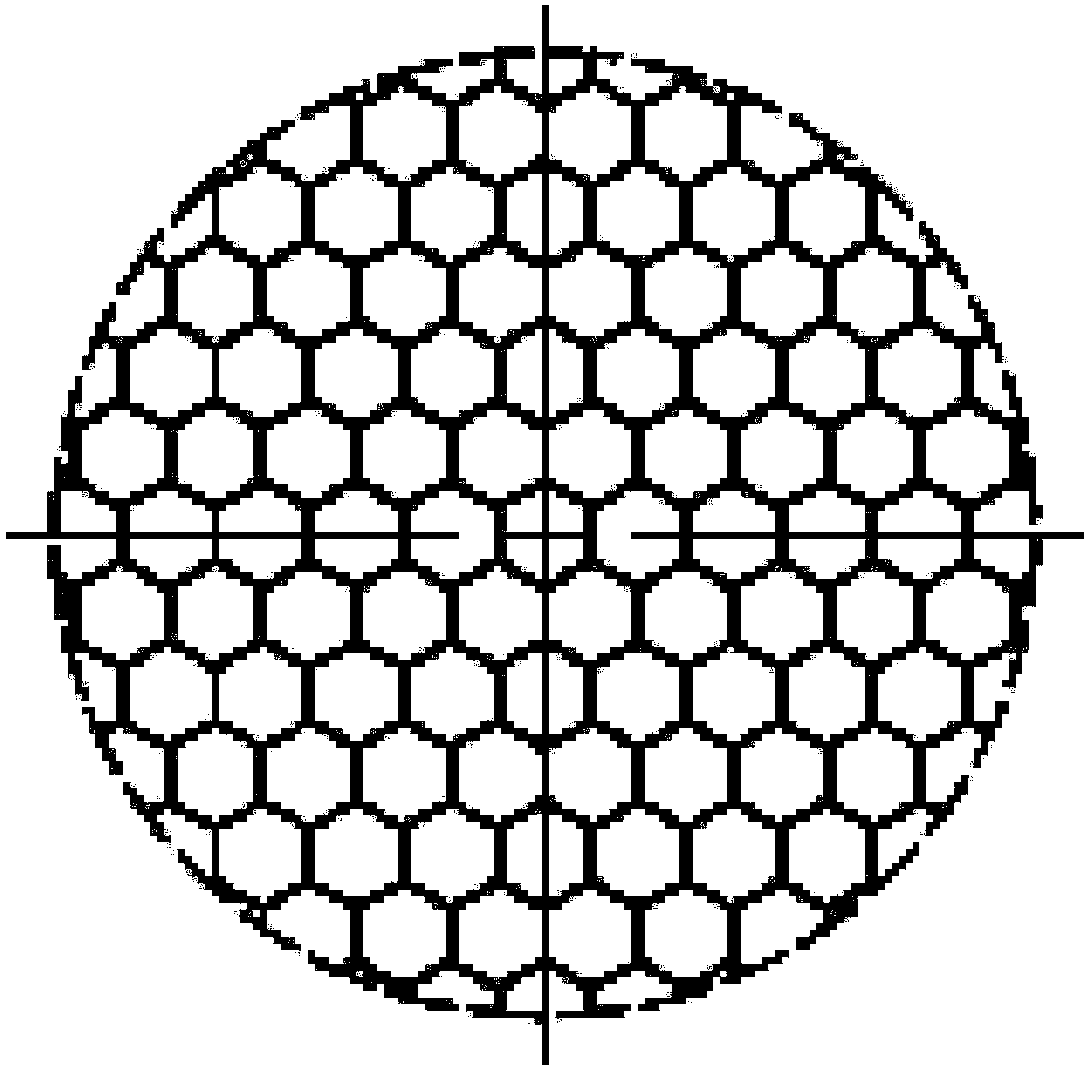

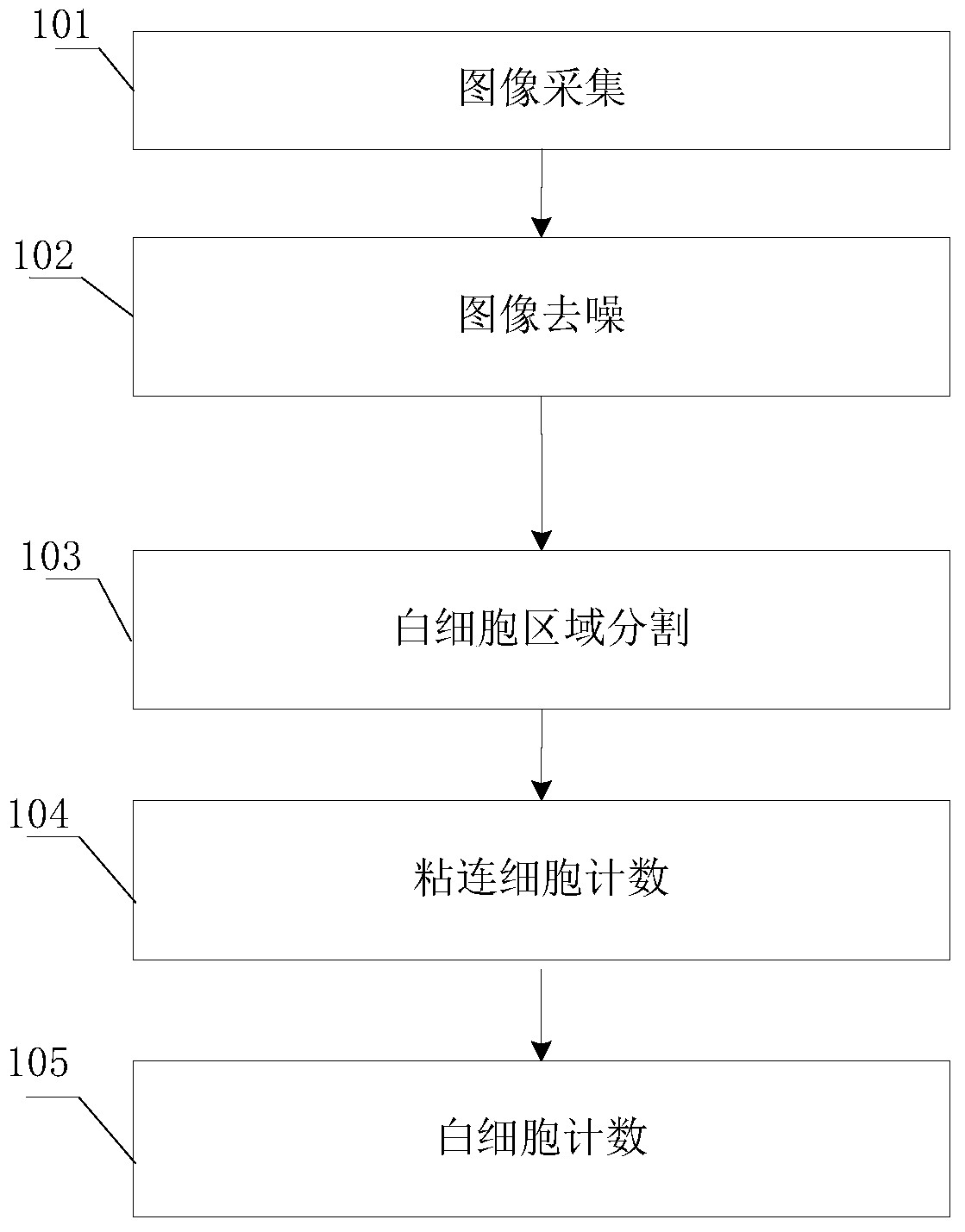

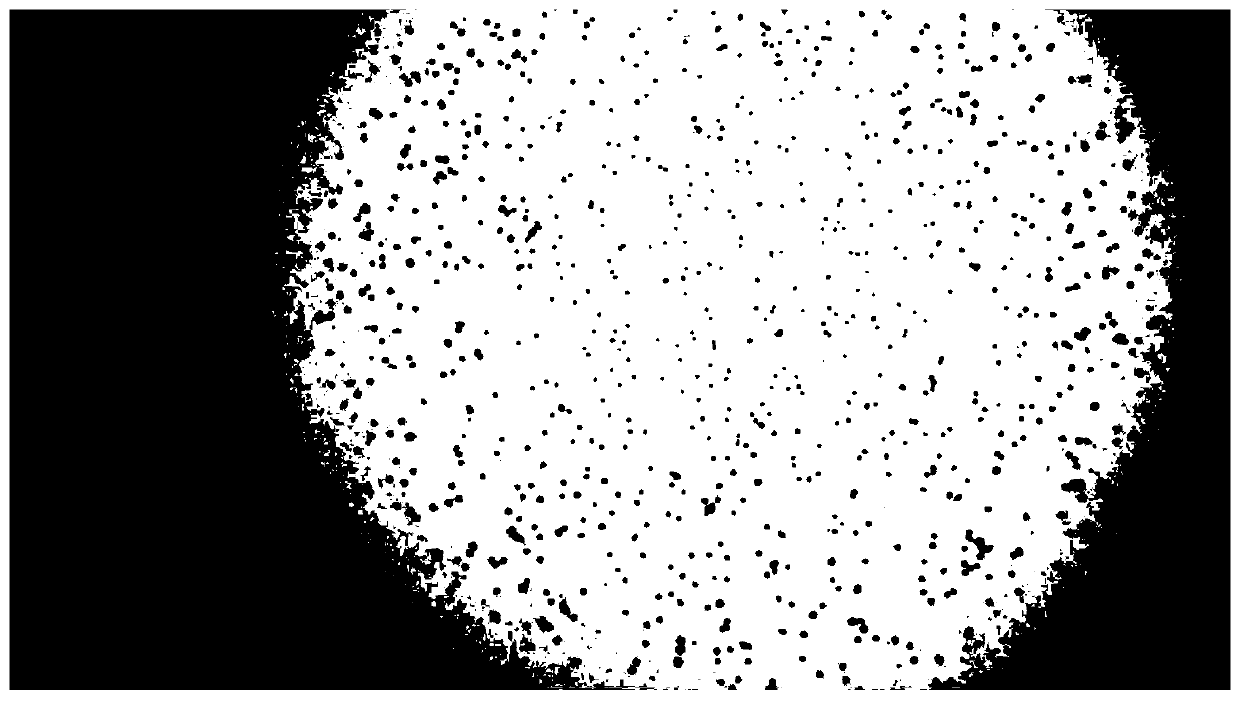

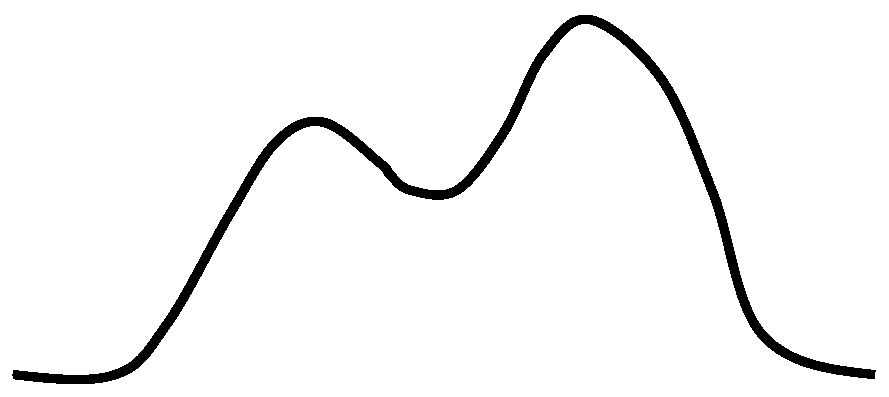

Image-based white blood cell counting method and system

ActiveCN108257124AAccurate CountingImprove Segmentation AccuracyImage enhancementImage analysisCell regionWhite blood cell

The invention relates to an image-based white blood cell counting method and system. The method includes the steps of collecting a blood sample image, removing image noise, conducting coarse segmentation on a cell region, obtaining the number of adherent cells, and obtaining the total number of white blood cells. According to the method, the segmentation accuracy of the white blood cells is higherby adopting a white blood cell automatic segmentation technique of an adaptive fuzzy clustering technology, the adherent cells with unapparent regions and chain code features can be quickly identified based on a three-dimensional surface adherent cell localization segmentation method, and the localization, counting and segmentation of the adherent cells are more accurate, so that the measurementof the number of the white blood cells is more accurate.

Owner:JIANGSU KONSUNG BIOMEDICAL TECH

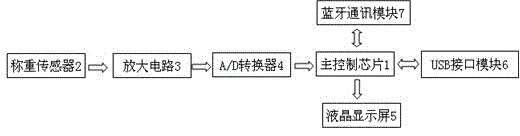

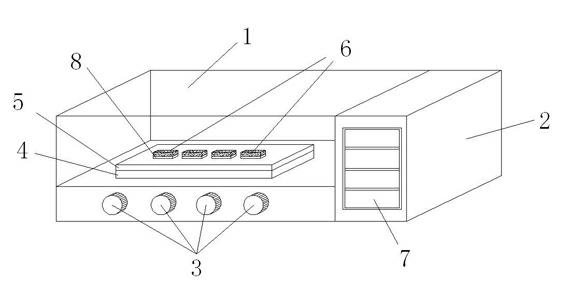

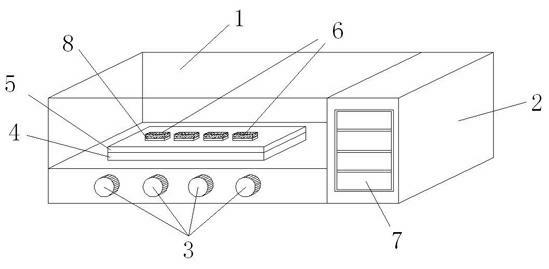

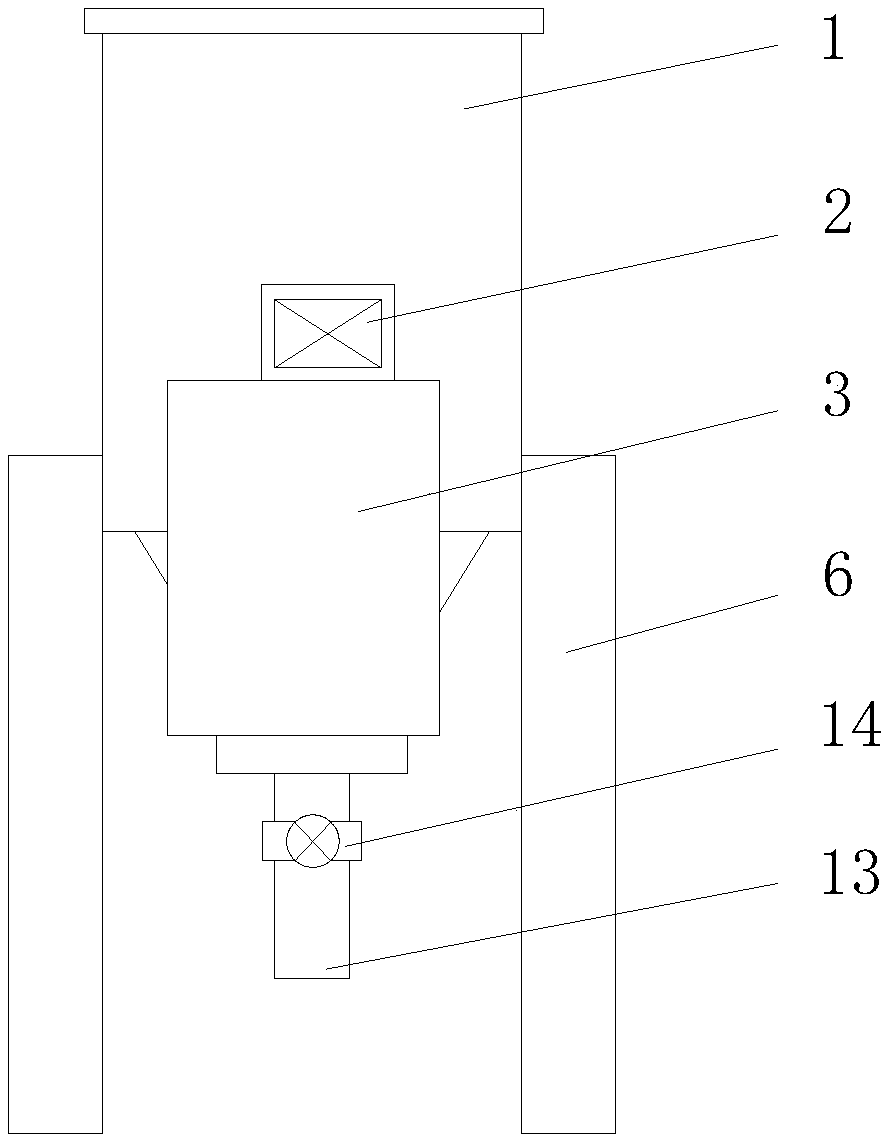

Portable electronic scale

InactiveCN104359535AReasonable structureReduce volumeWeighing apparatus using electromagnetic balancingElectricityBuck converter

The invention discloses a portable electronic scale which comprises a plastic machine shell and a stainless steel scale tray embedded on the opening face of the plastic machine shell. The portable electronic scale can be connected with an external printer through a USB interface. The portable electronic scale comprises a hardware system which is composed of a main control chip, a weighing sensor, an amplification circuit, an A / D converter, an LCD screen and a USB interface module, wherein the weighing sensor, the amplification circuit, the A / D converter, the LCD screen and the USB interface module are electrically connected with the main control chip, and the weighing sensor is an electromagnetic force balance sensor. Through the above mode, the portable electronic scale is small in size and accurate and quick in measurement, integrates the function of weighing and the function of price calculation, can be connected with external equipment, and provides the function of printing or data transmission.

Owner:常熟市佳衡天平仪器有限公司

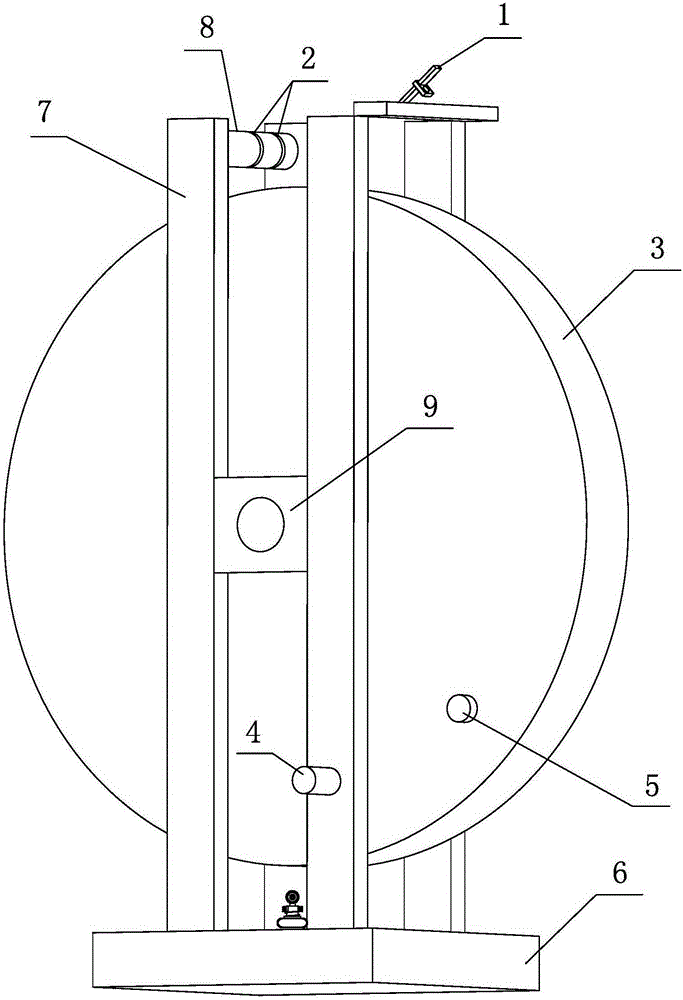

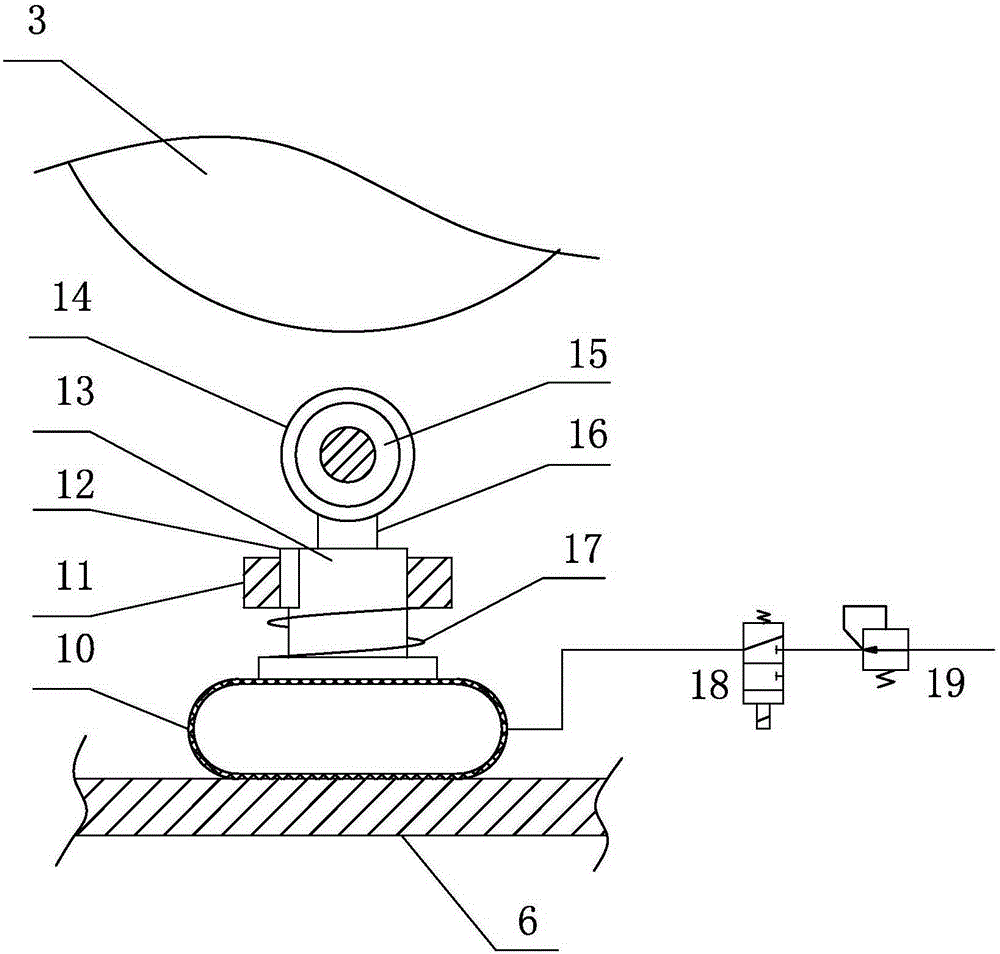

Rubber tube braiding wire quantification method

ActiveCN105222670AAvoid displacementAccurate measurementMechanical measuring arrangementsControl systemQuantification methods

The invention relates to a rubber tube braiding wire quantification method. A side of an outer circumference of a meter remembering wheel is provided with a wire rod inlet and a wire rod outlet. A wire rod to be winded is winded on the meter remembering wheel via the wire rod inlet, then is removed from the meter remembering wheel via the wire rod outlet and is winded on a wire shaft of a stranding machine. The wire shaft is rolled and the wire rod is rotated along with a reel and drives the meter remembering wheel to rotate. Through a proximity switch, trigger equipment and an external control system, effective rotation turns of the meter remembering wheel are recorded and calculated. According to a wire rod length of single turn winding of the meter remembering wheel, the control system calculates the wire rod length which is winded into the wire shaft of the stranding machine. By using the method, metering is accurate and rapid and high reliability is possessed.

Owner:宁波世峻汽配科技有限公司

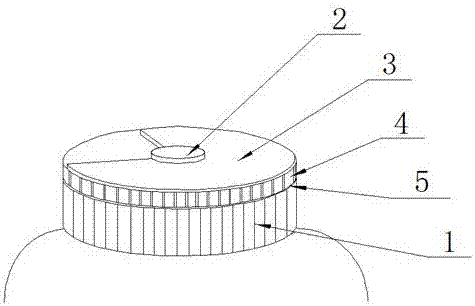

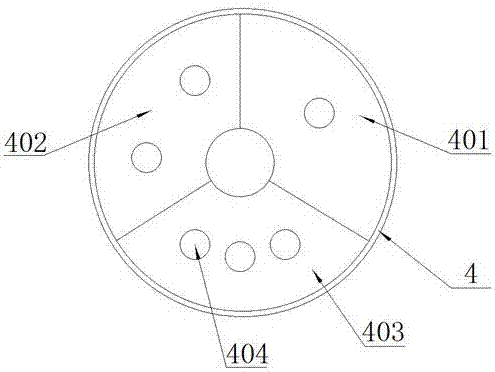

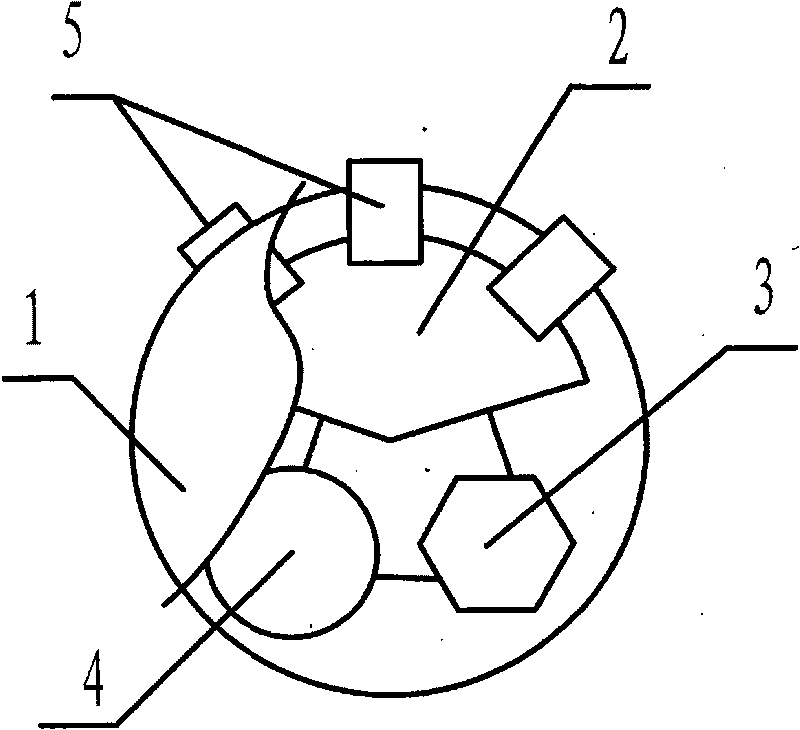

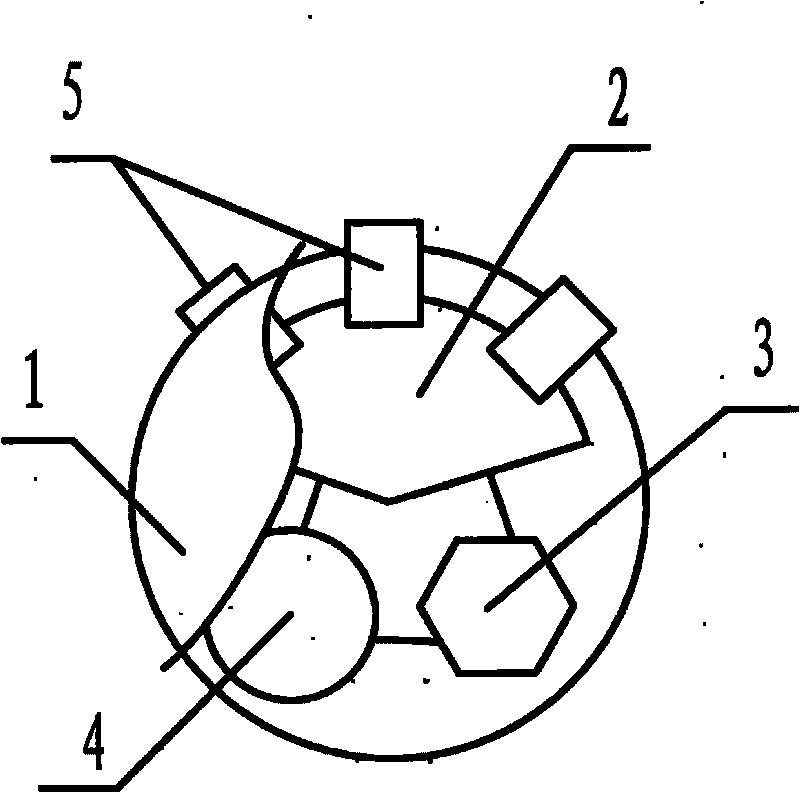

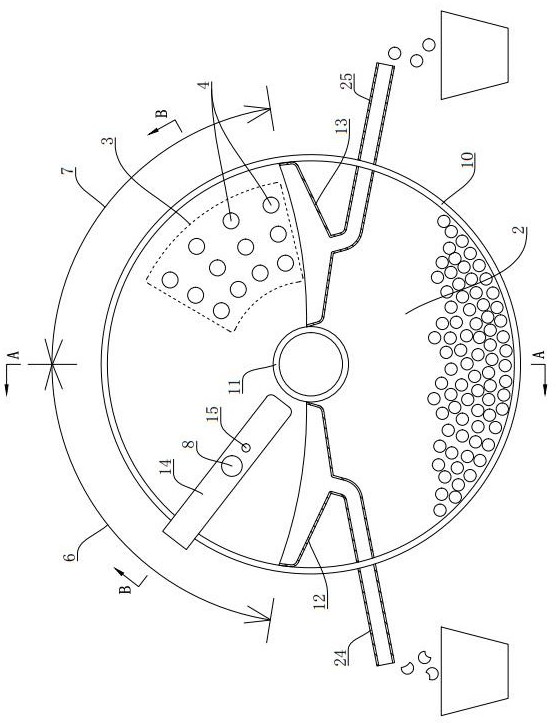

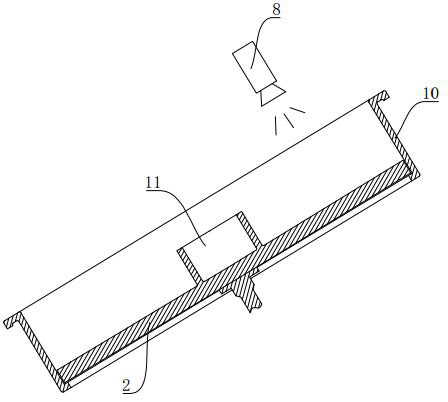

Pill particle counter

InactiveCN108001878AAccurate measurementFast meteringSmall article dispensingBottle capParticle counter

The invention relates to a pill particle counter. The device comprises a bottle cap body, wherein the bottle cap body comprises a connecting part; a first separation piece, a counting box and a secondseparation piece sequentially penetrate through the a connecting part; the first separation piece, the counting box and the second separation piece are rotated in a staggered manner two by two; the thickness of the counting box is 3mm to 6mm; the counting box is equally divided into a first region, a second region and a third region; one medicine taking hole is opened in the first region; two medicine taking holes are opened in the second region; three medicine taking holes are opened in the third region; the diameter of each medicine taking hole is 5mm to 15mm; and notches matched with the counting box are opened in the first separation piece and the second separation piece. The counting box, the first separation piece and the second separation piece are matched to use so that tablets with a required quantity can be accurately and rapidly taken out according to requirements of different users.

Owner:韩逸哲

Polyvinyl chloride powder ingredient stirring device

InactiveCN108284533AImprove the effect of impurity removalIncrease exerciseSievingScreeningAdditive ingredientPolyvinyl chloride

The invention discloses a polyvinyl chloride powder ingredient stirring device and belongs to the technical field of PVC film production equipment. The polyvinyl chloride powder ingredient stirring device is characterized by comprising a vibration screening device, a collection tank, a conveyor and a stirring barrel; the lower end of the vibration screening device is provided with a circular arc-shaped guide plate protruding upwards; the lower end of the vibration screening device is provided with a discharge pipe inclined downwards; the bottom end of the collection tank is provided with a flange used for being connected with the conveyor; the outer side of the collection tank is provided with a fixing rack II used for supporting the collection tank; the lower end of the fixing rack II isprovided with a loadometer; the upper end of the conveyor is provided with a bearing block fixed to a conveying shaft; a dustproof cover is arranged at the tail end of an outlet of the conveyor, and the stirring barrel is arranged at the lower end of the outlet of the conveyor correspondingly. The polyvinyl chloride powder ingredient stirring device achieves the effects of being reasonable in structure design, capable of avoiding pollution to raw materials, high in conveying efficiency, accurate in ingredient stirring and uniform in stirring.

Owner:YIWU SHUNDA PLASTIC CO LTD

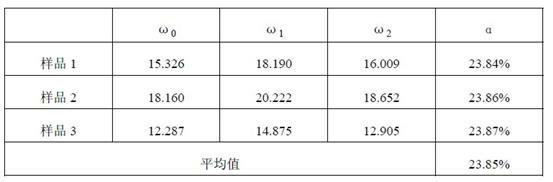

Method and equipment for measuring total solid matter content of natural rubber latex

InactiveCN102252938ALower the boiling point of evaporationQuick extractionWeighing by removing componentPolymer scienceSolid matter

The invention provides a method for measuring total solid matter content of natural rubber latex. The method is accurate, quick and easy to operate and can replace a standard oven drying method. The invention also provides equipment for measuring the total solid matter content of the natural rubber latex.

Owner:刘光辉 +1

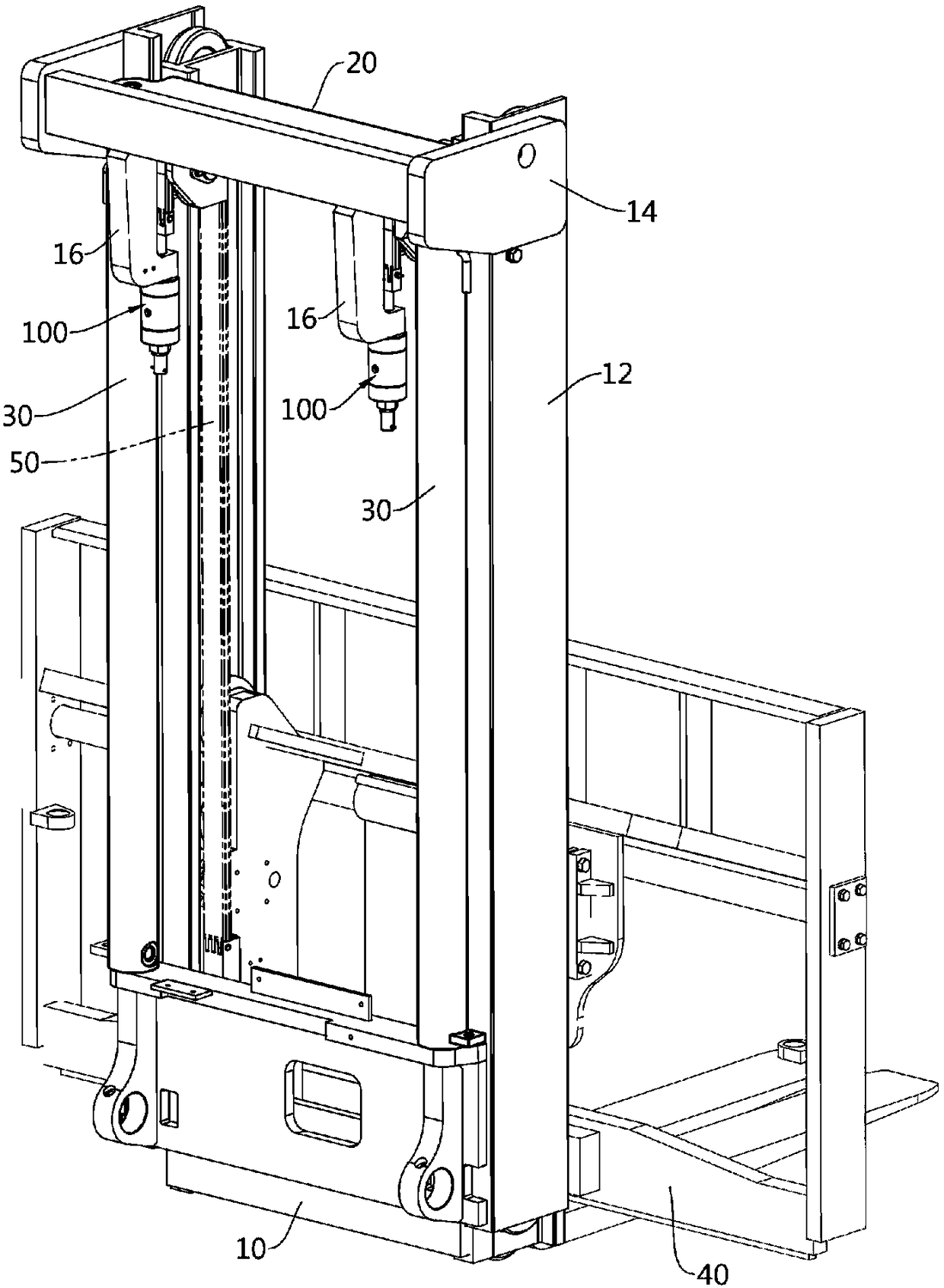

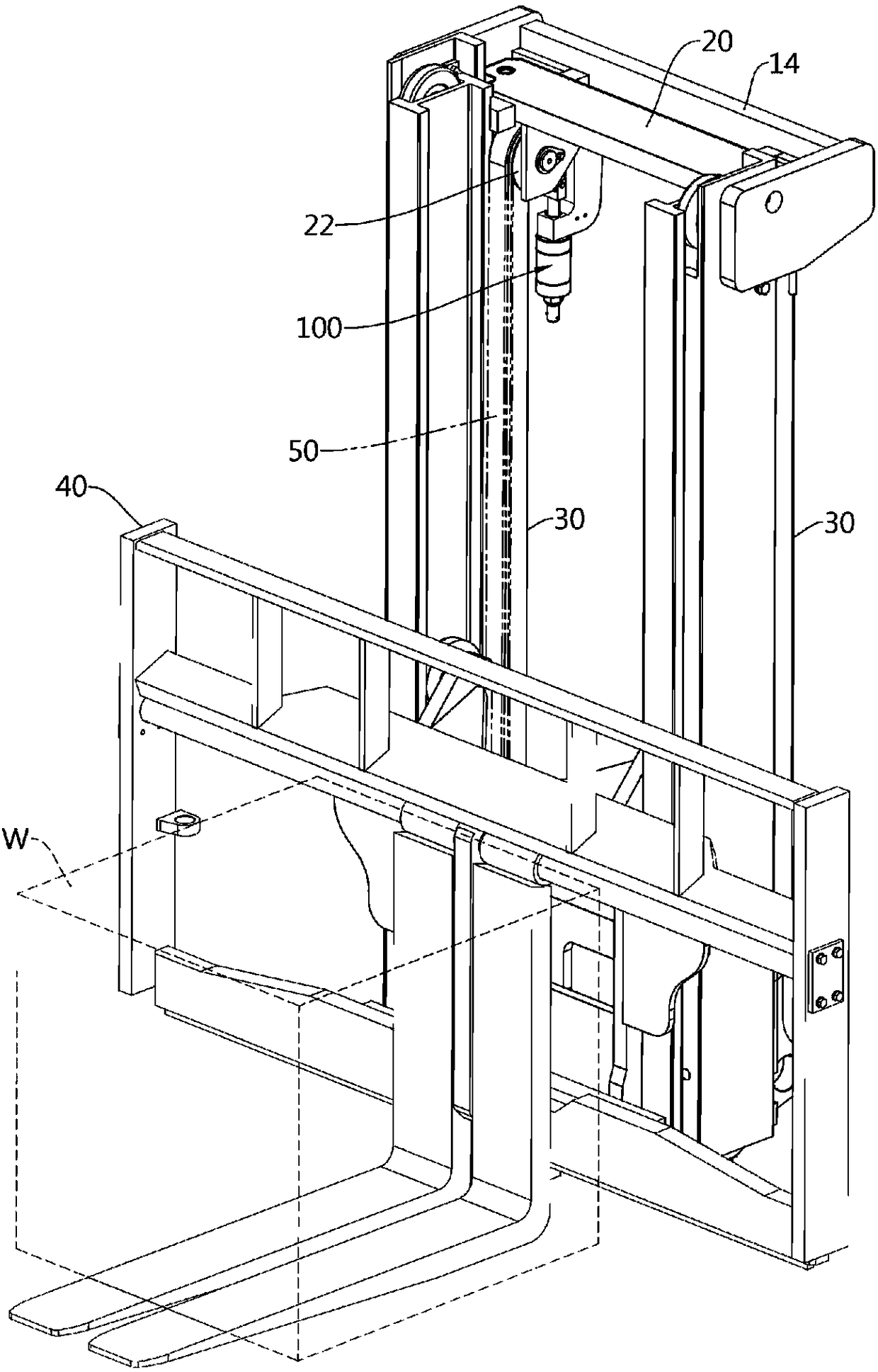

Forklift

InactiveCN108473290AImprove reliabilityAvoid damageSafety devices for lifting equipmentsVehiclesEngineeringForklift truck

Owner:DOOSAN CORP

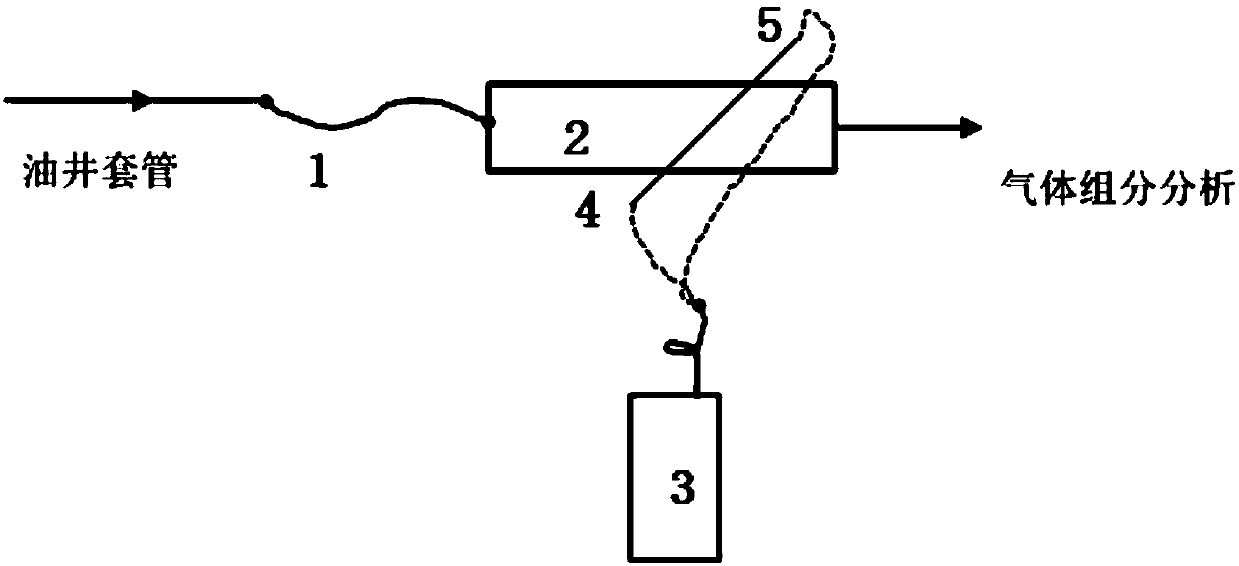

Device and method for metering gas volume of oil-well sleeve gas

The invention provides a device and method for metering the gas volume of oil-well sleeve gas. The device comprises a port flexible pipe, a multiple-effect constant-current detection pipe and a gas flow meter, wherein one end of the port flexible pipe is connected with an oil-well sleeve, and the other end of the port flexible pipe is connected with the multiple-effect constant-current detection pipe; the multiple-effect constant-current detection pipe is used for enabling the oil-well sleeve gas to stably pass through; two fixing clamps are arranged on the outer wall of the multiple-effect constant-current detection pipe and used for fixing two detection probes of the gas flow meter. The invention also provides a method for metering the gas volume of the oil-well sleeve gas with the device. According to the device and method, the gas volume of sleeve gas with different pipe diameters, different pressures and different flows can be rapidly assessed at an oil-well opening.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

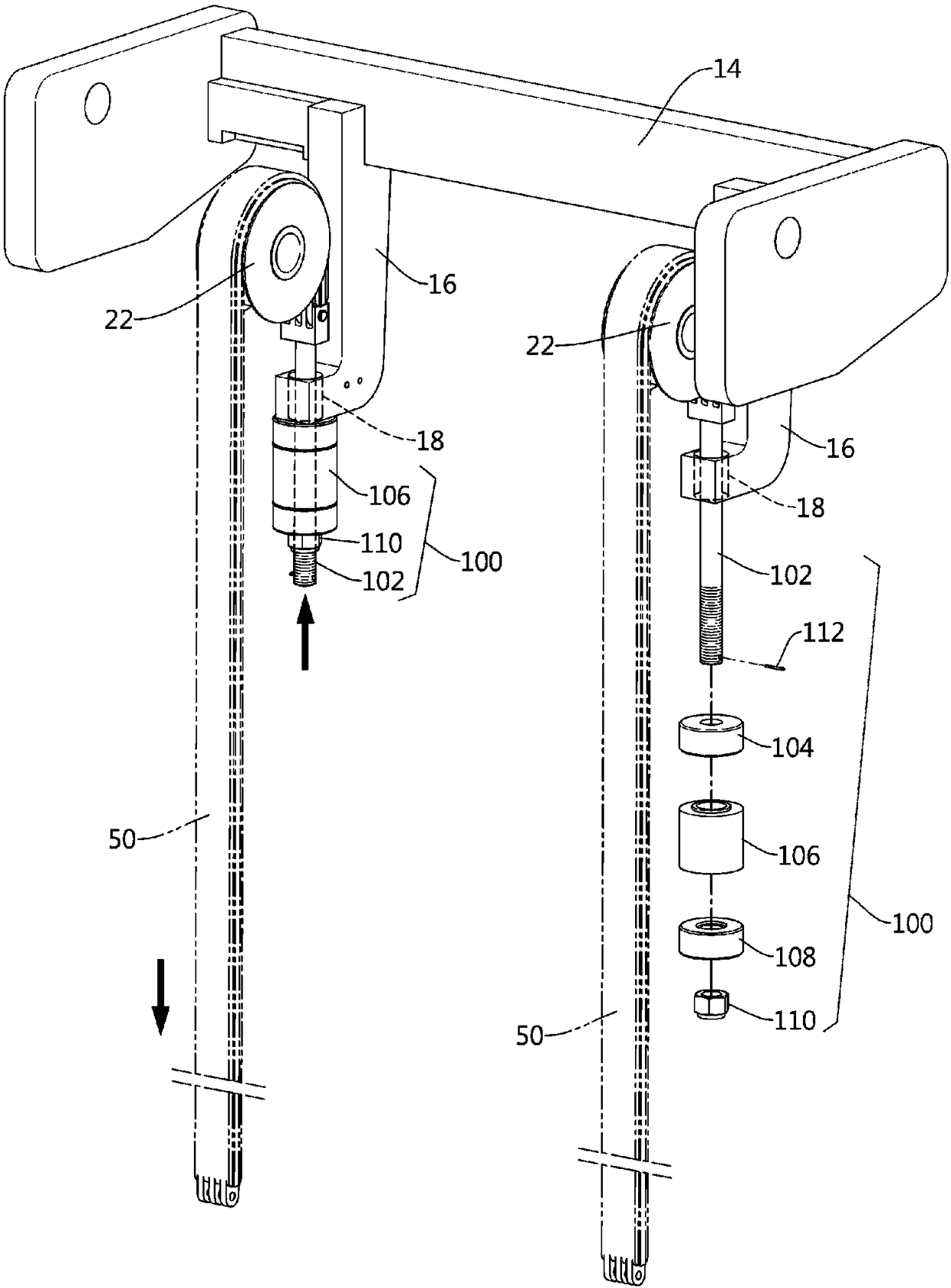

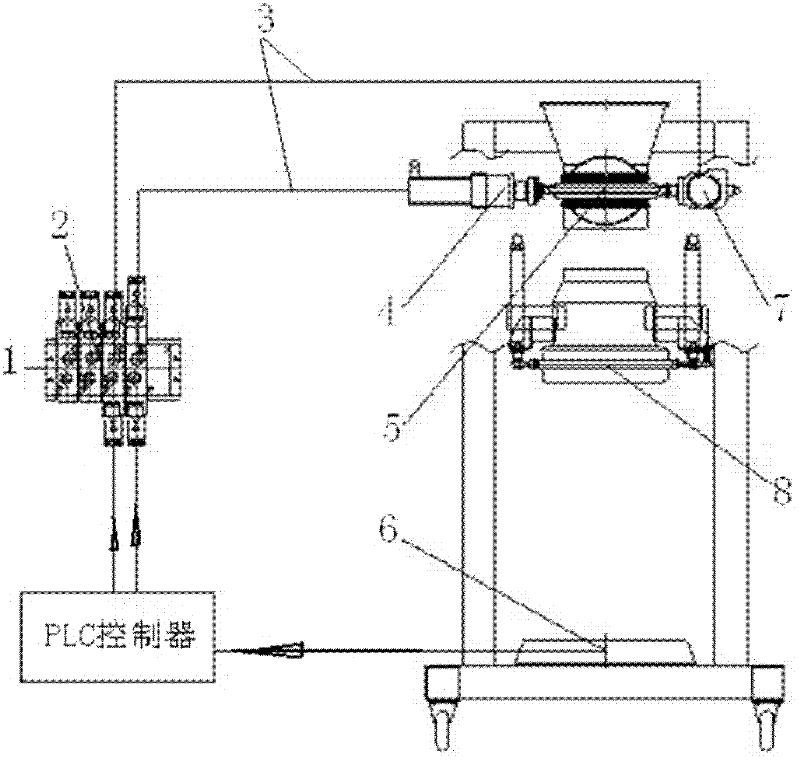

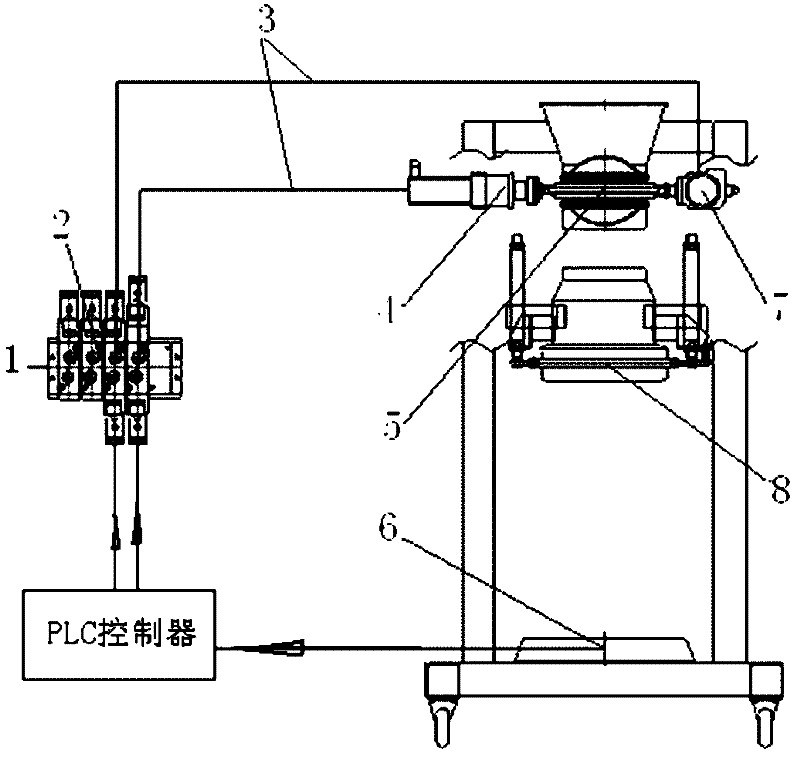

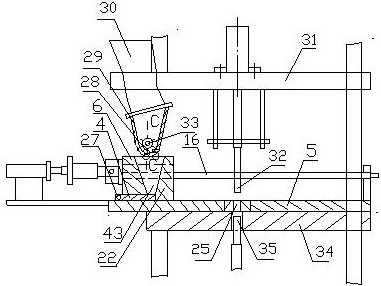

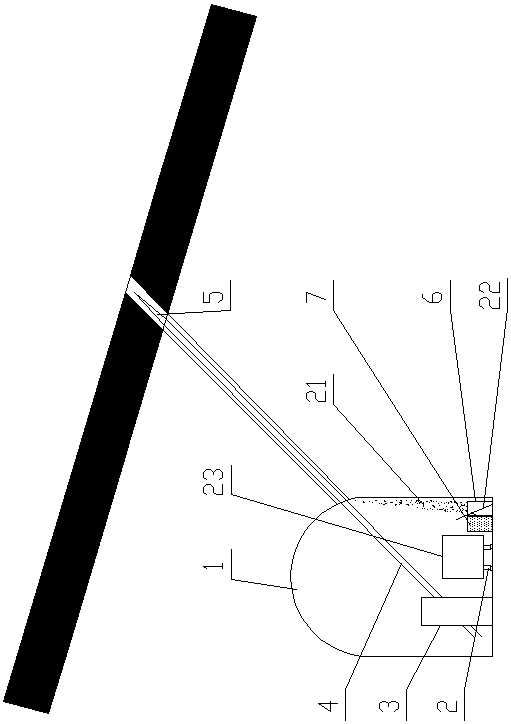

Feeding mechanism of metering racking machine

InactiveCN102398687AFast meteringThe metering and dispensing machine feeds quicklySolid materialDrive shaftPneumatic motor

The invention discloses a feeding mechanism of a metering racking machine, which comprises a rotary racking valve; the rotary racking valve comprises a big rotor; a small rotor is arranged in the big rotor; the big rotor and the small rotor are coaxial in center of gyration; the drive shaft of the big rotor is connected with a pneumatic actuator; and the drive shaft of the small rotor is connected with a pneumatic motor. The big rotor and the small rotor are driven by the pneumatic actuator and the pneumatic motor which take compressed air as power to respectively realize rapid and accurate feeding. The feeding mechanism of the metering racking machine has a simple structure, convenience in speed regulation and accuracy in metering.

Owner:BEIJING CHIEFTAIN CONTROL ENG TECH

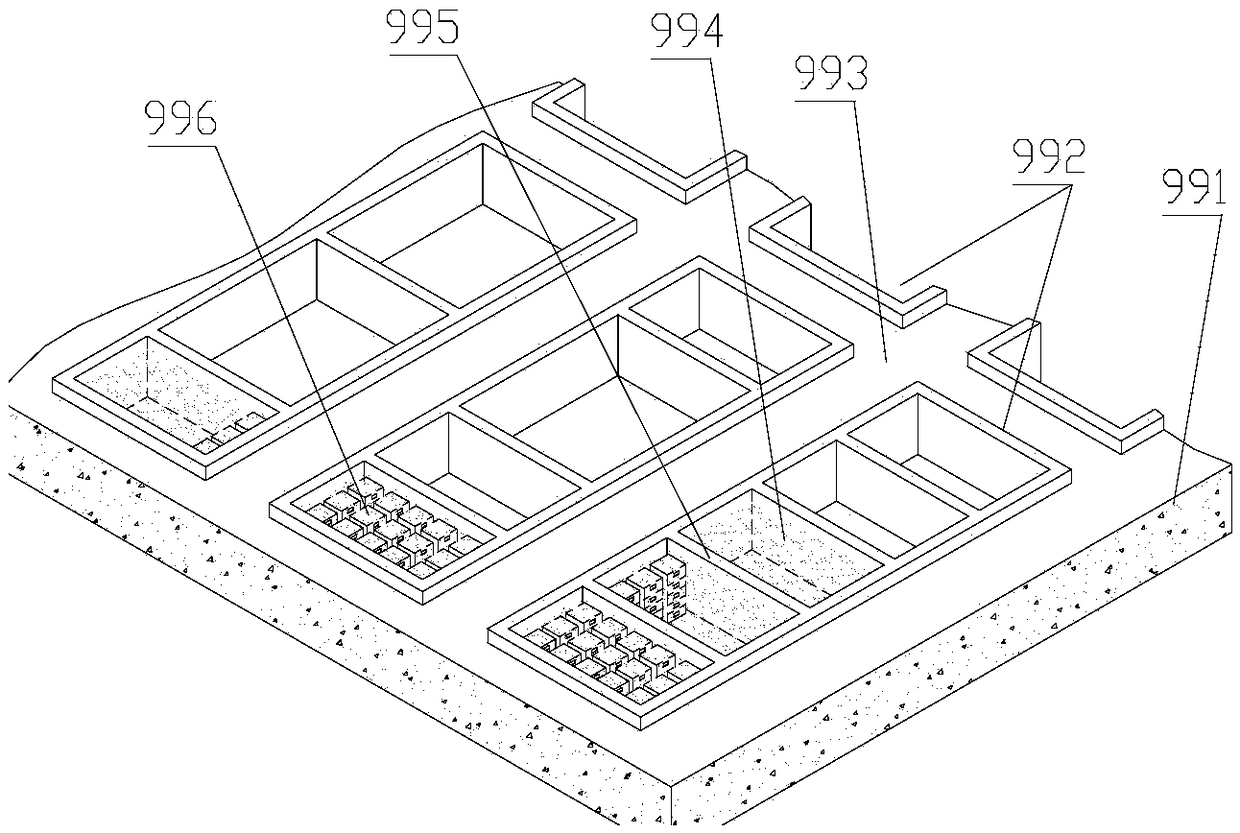

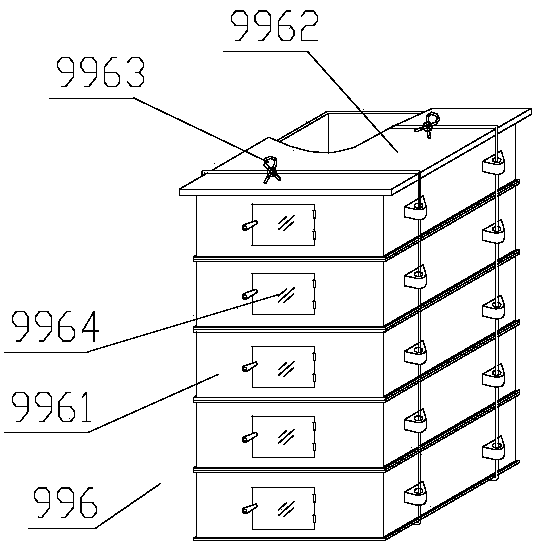

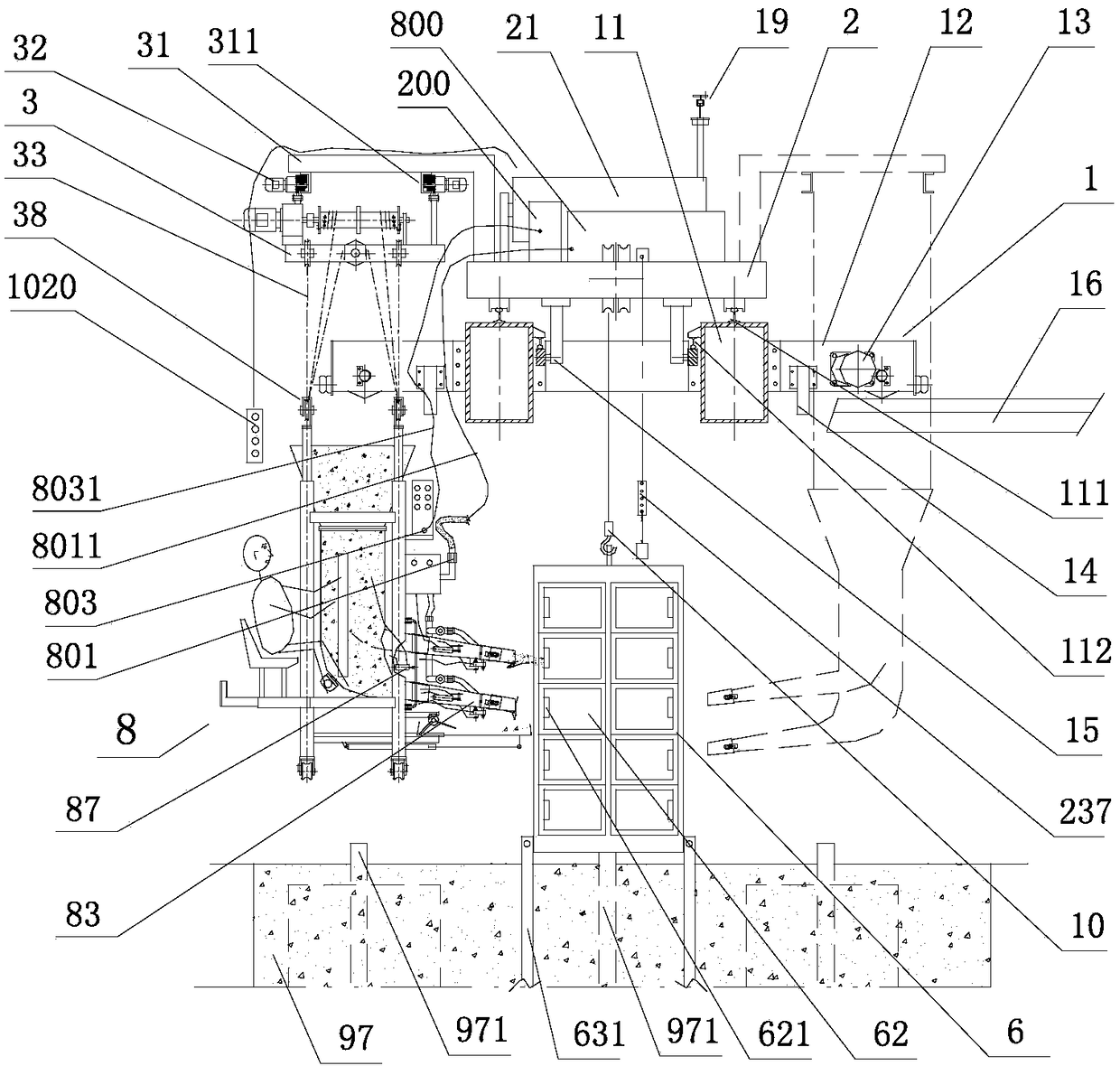

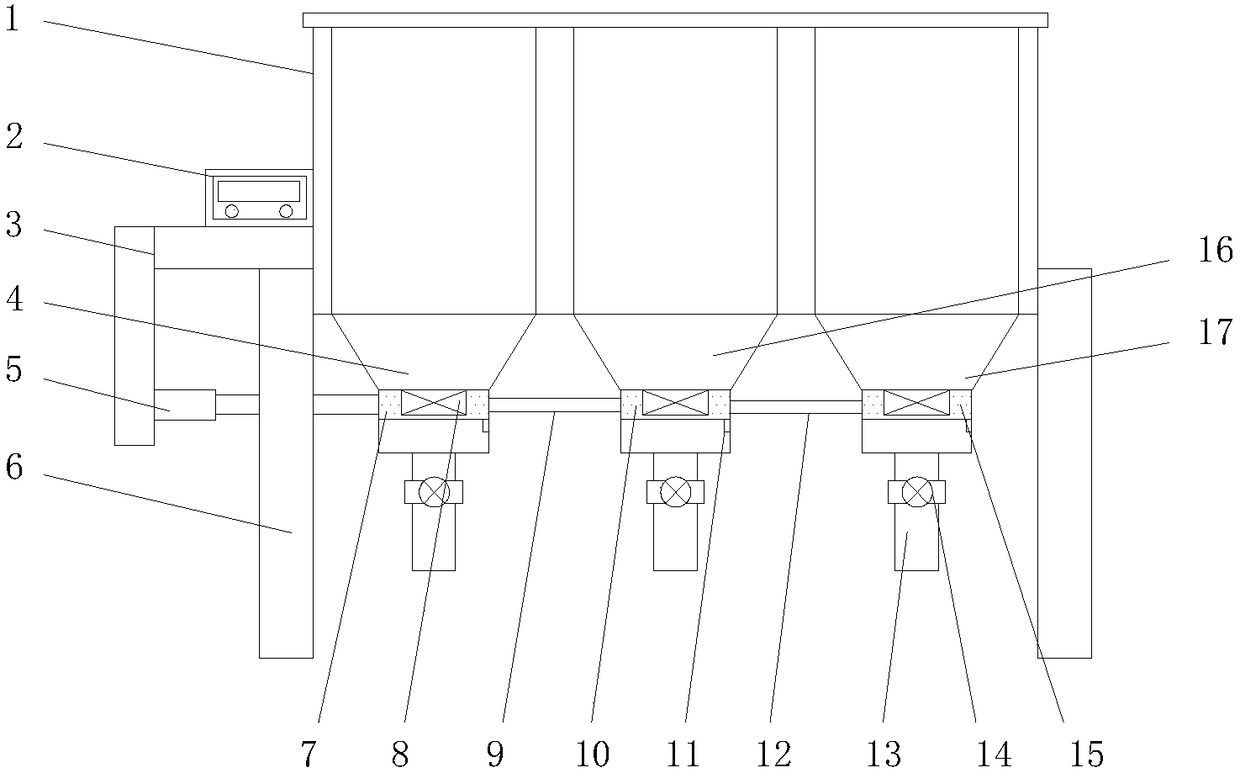

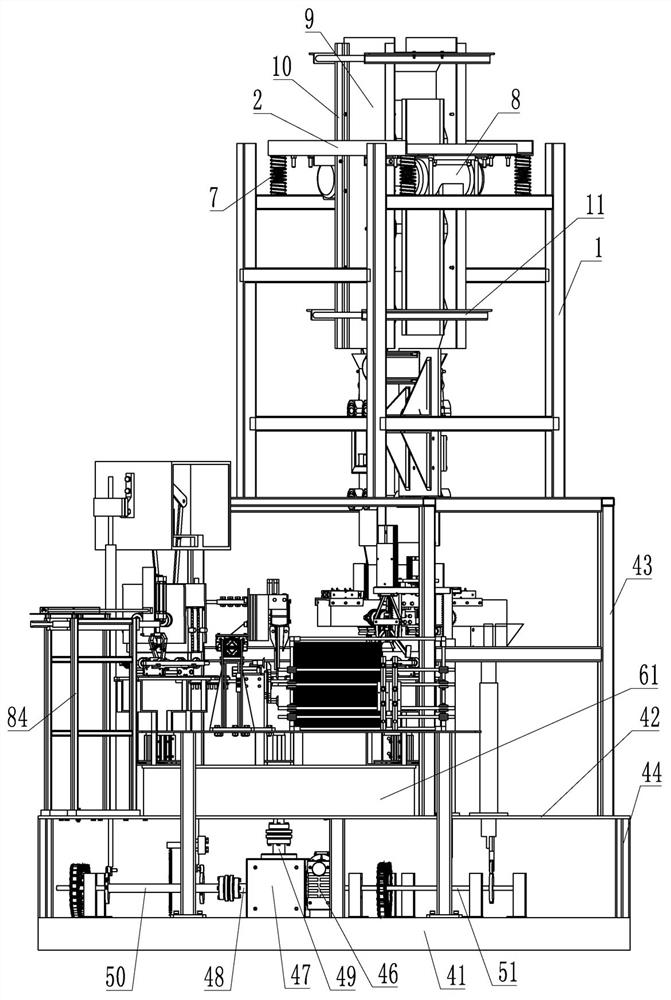

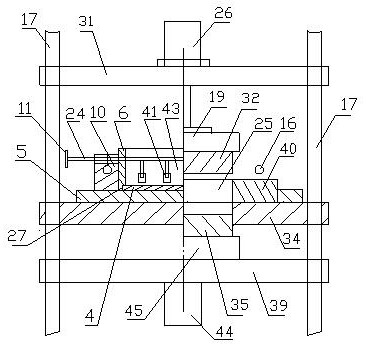

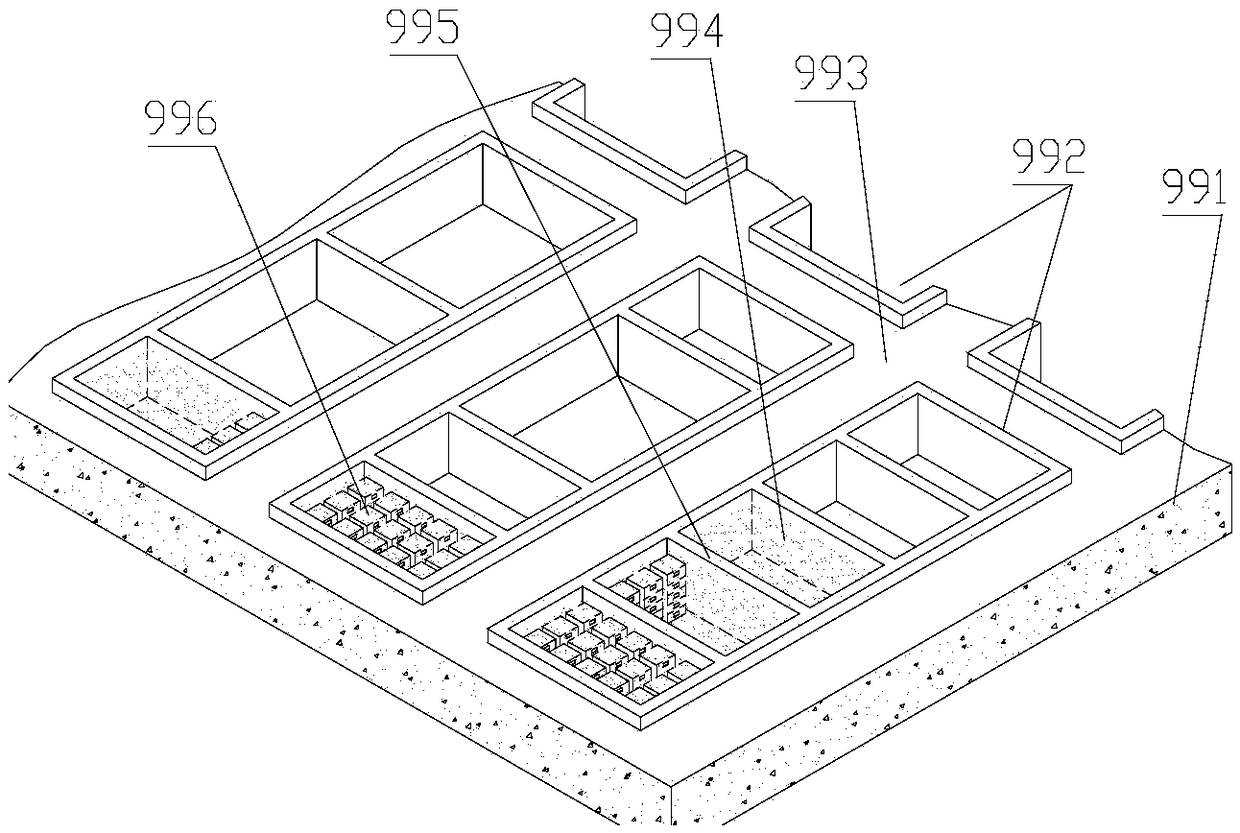

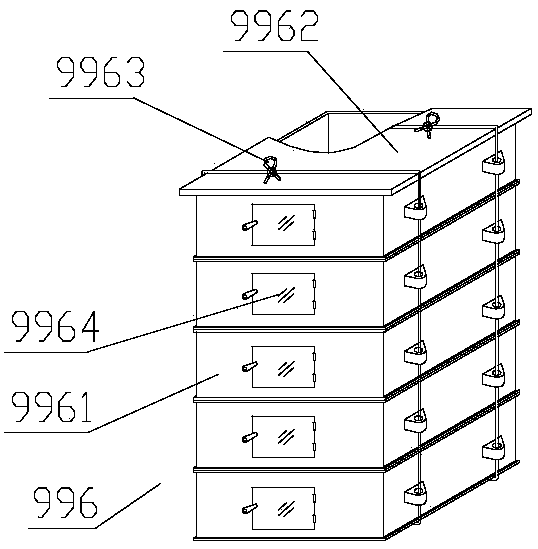

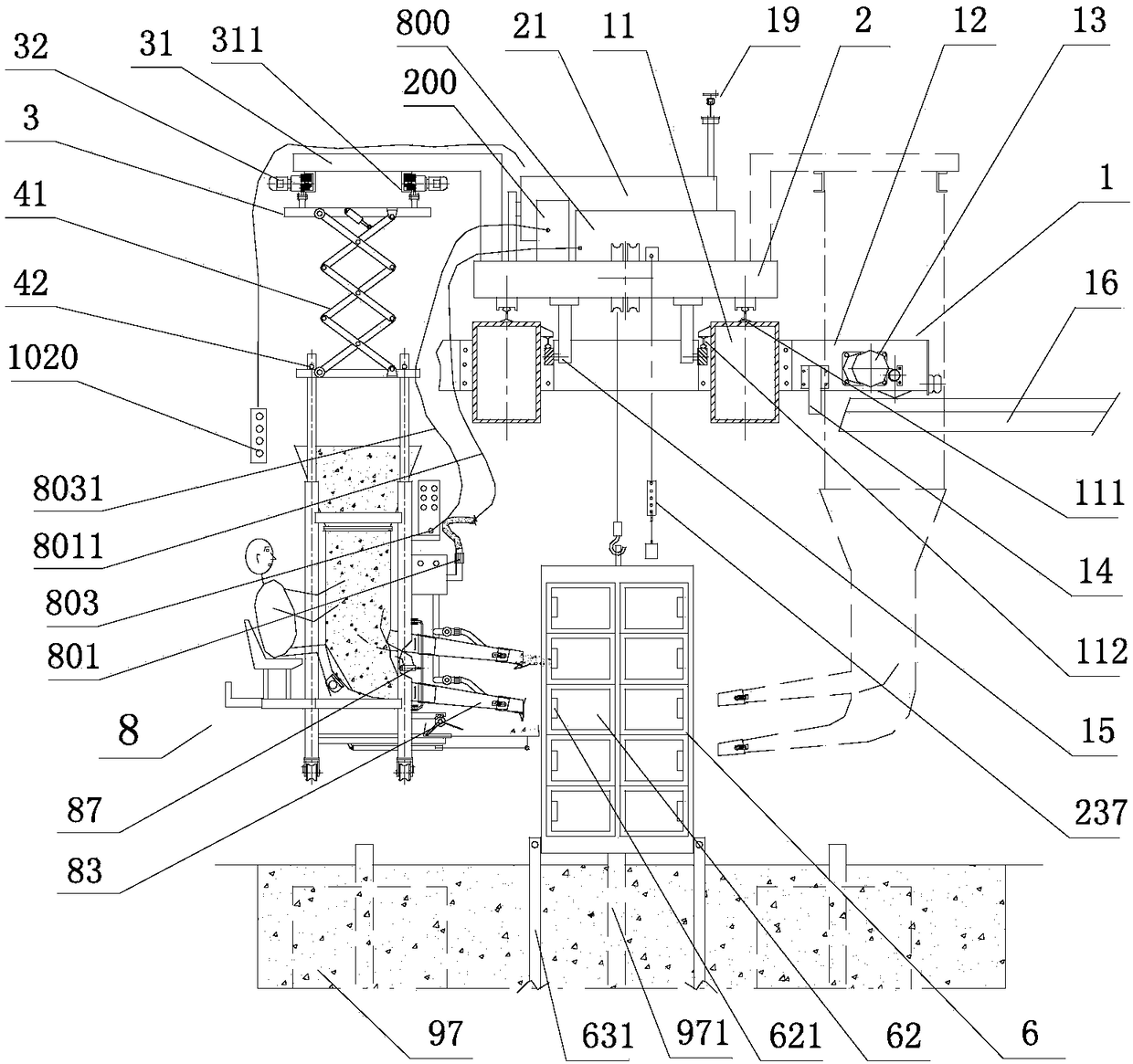

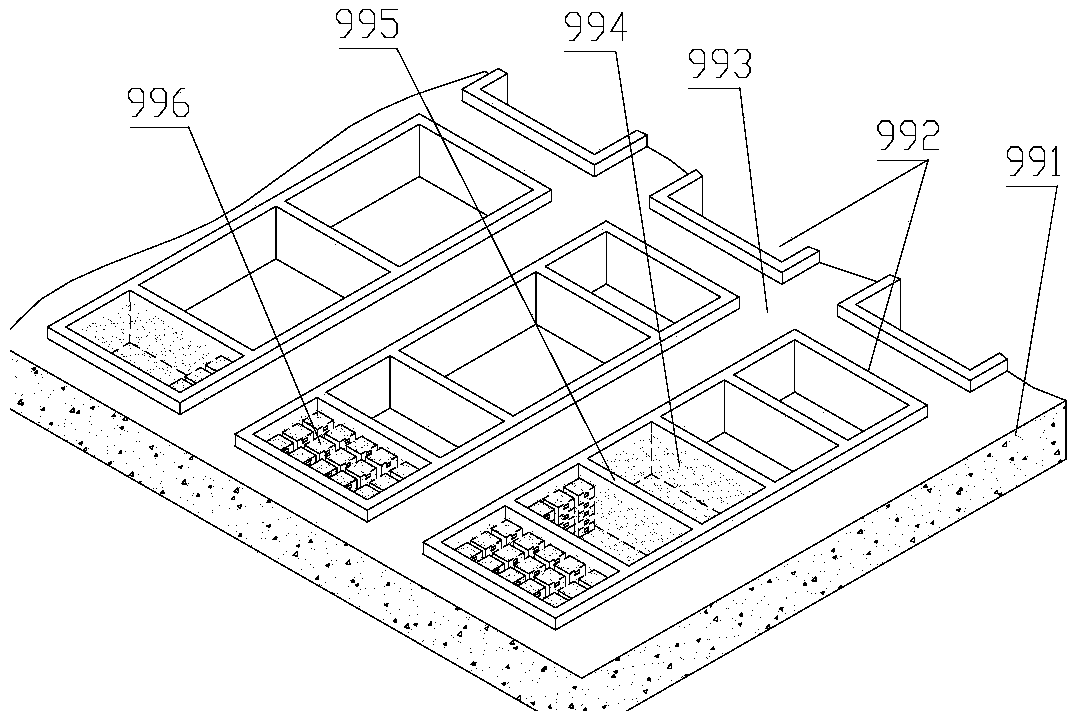

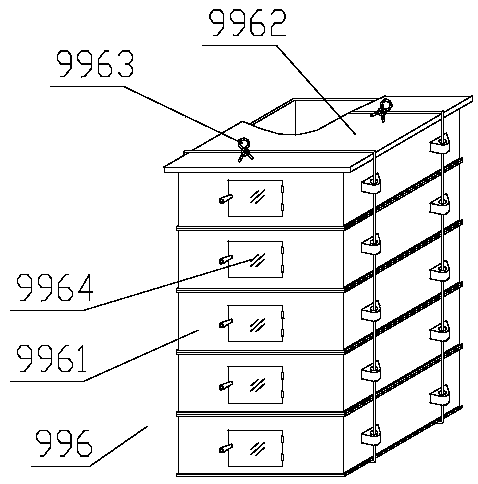

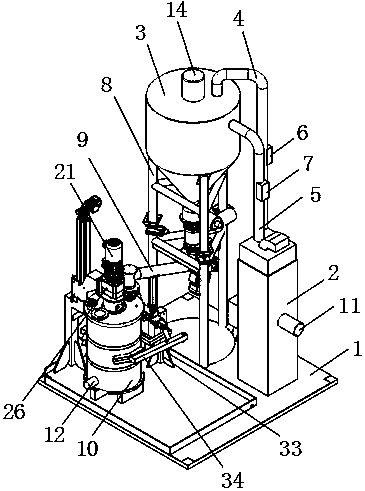

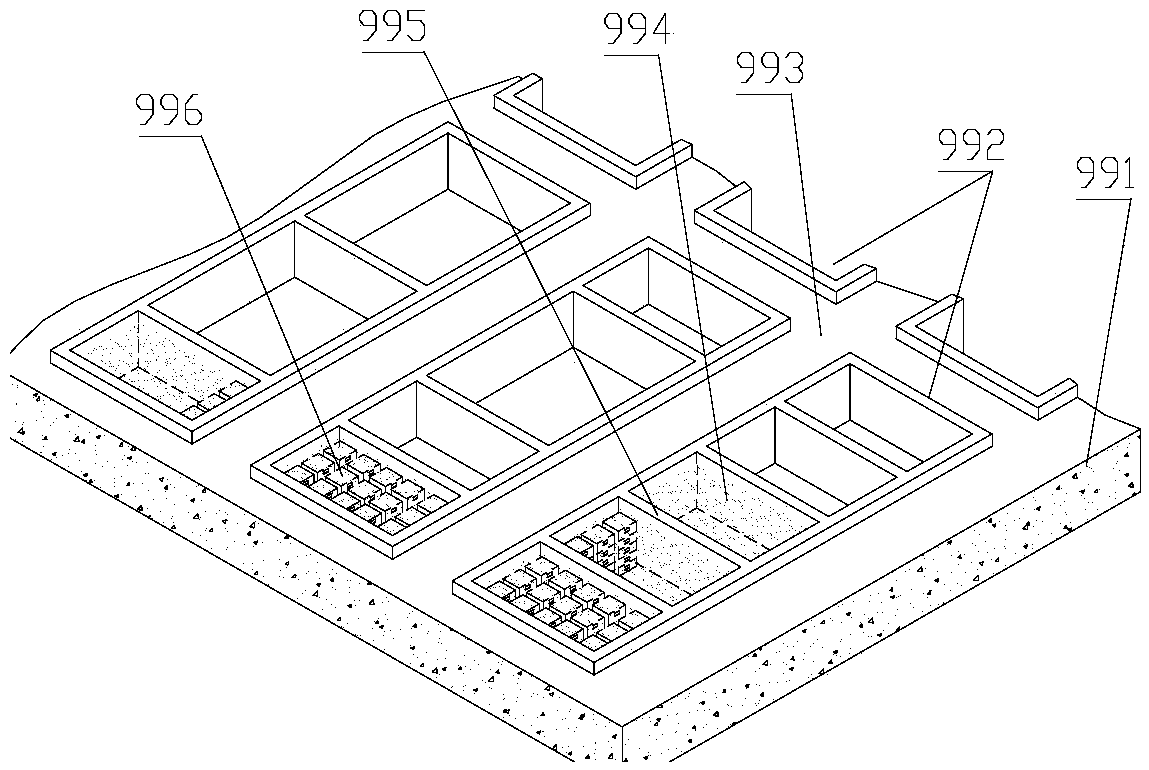

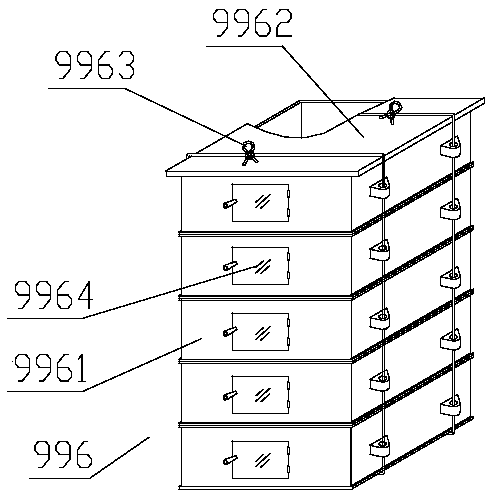

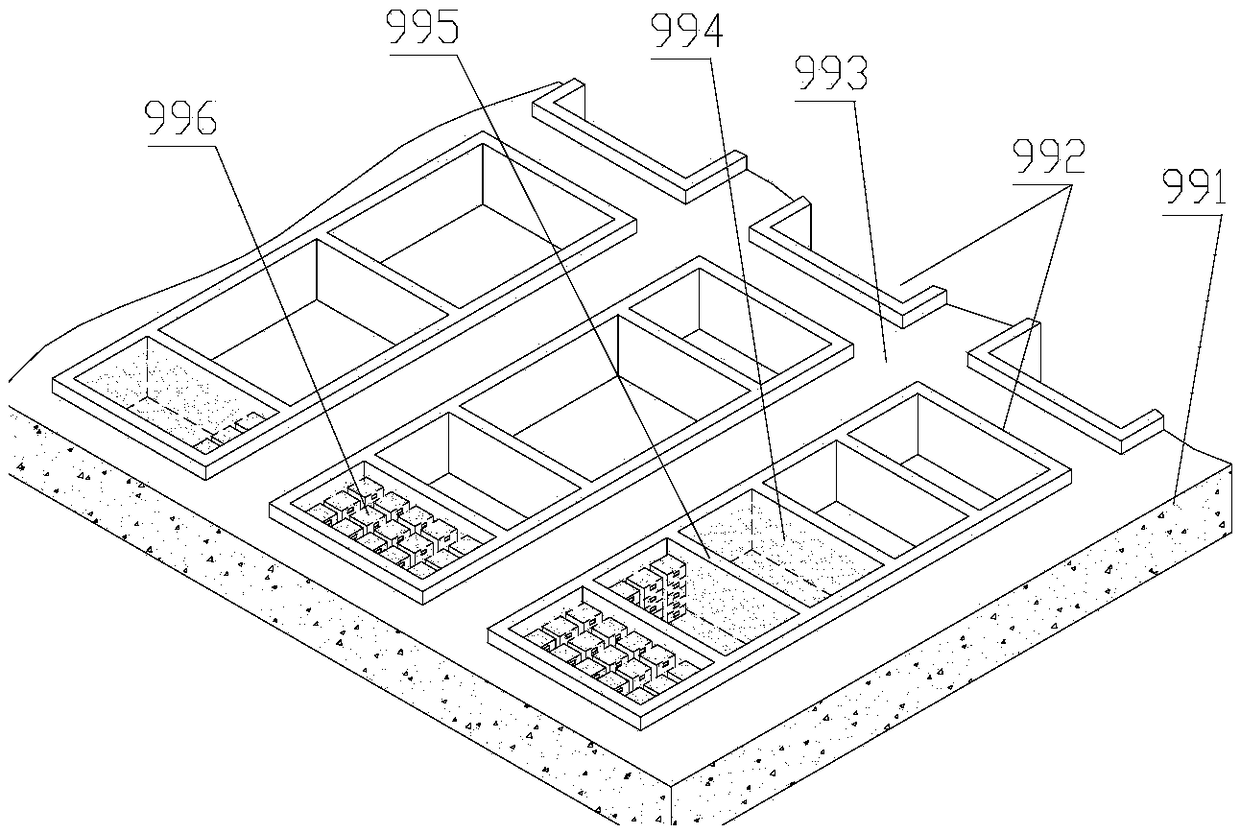

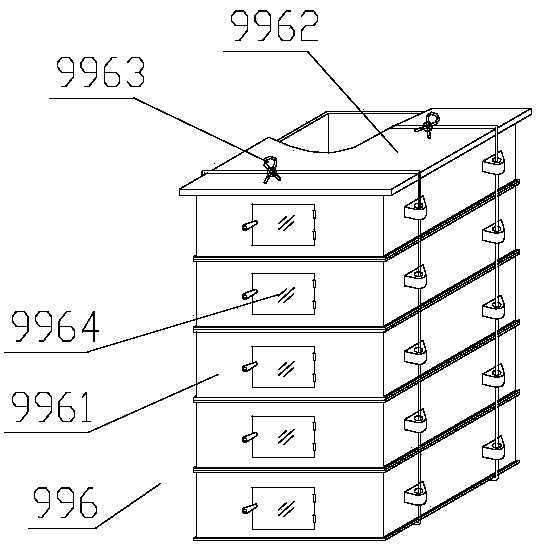

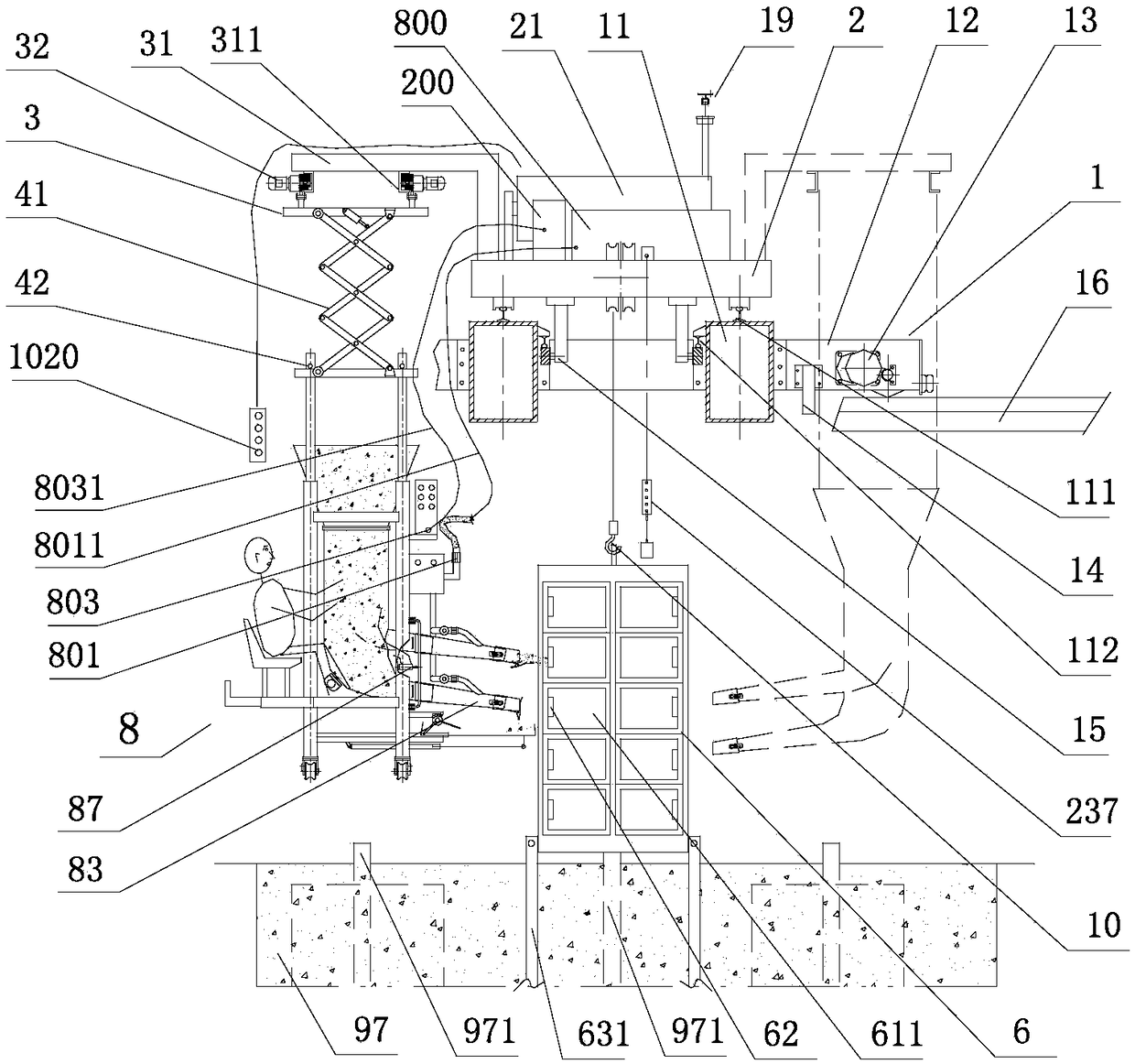

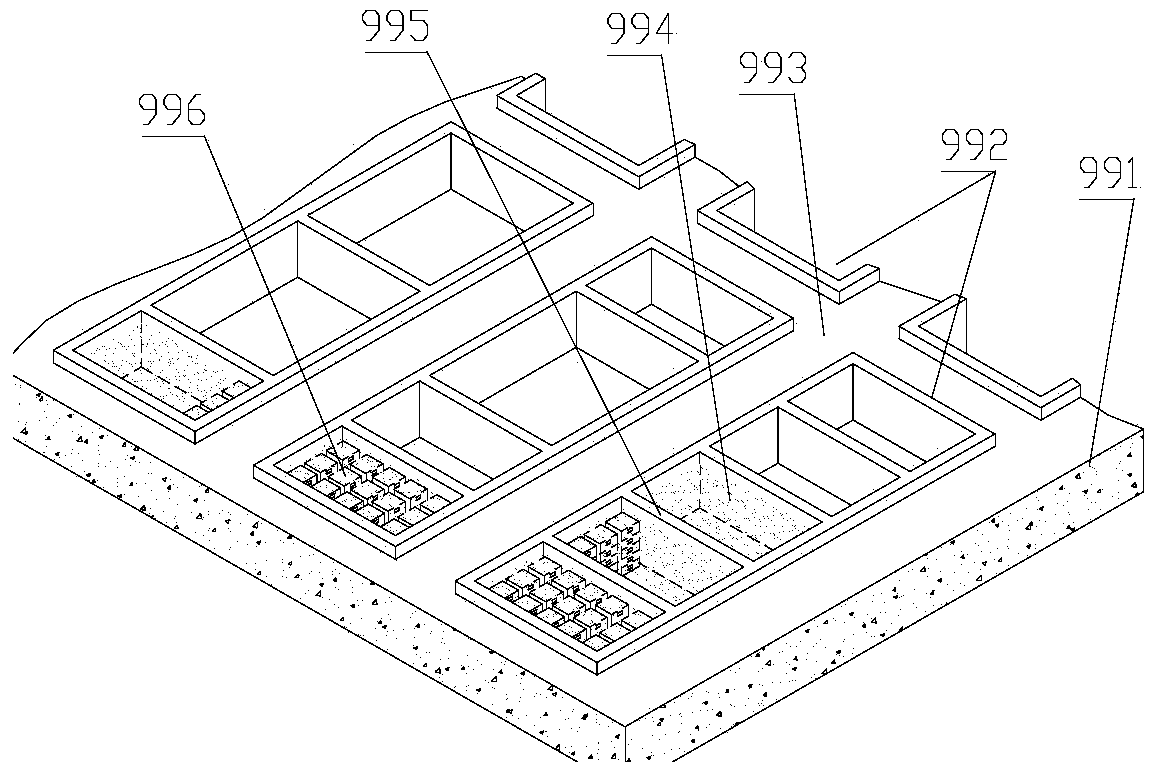

Aquaculture feeding system with bridge crane and weighing feeder

InactiveCN109418206AAccurate positioning and quantitative feedingReduce workshop aislesClimate change adaptationPisciculture and aquariaEngineeringOverhead crane

The invention discloses an aquaculture feeding system with a bridge crane and a weighing feeder. The aquaculture feeding system includes an aquaculture pond, at least one aquaculture cabinet, a craneand a feeder; a wheel tread of a cart running device of the crane runs, pressing on workshop tracks above rail-bearing beams, and the two rail-bearing beams are separately connected to brackets of workshop upright columns at both sides of the aquaculture pond; the at least one aquaculture cabinet is placed in the aquaculture pond; the crane comprises one or more trolley devices, and each trolley device is connected with one or two feeders and operates with the crane; the feeder is equipped with a weighing system, and the weighing system can weigh and measure the feed in a metering mouth of thefeeder; and hooks on the crane lift the at least one aquaculture cabinet to the pond surface of the aquaculture pond, and the feeder feeds the at least one aquaculture cabinet quantitatively throughhigh pressure gas.

Owner:黄滨

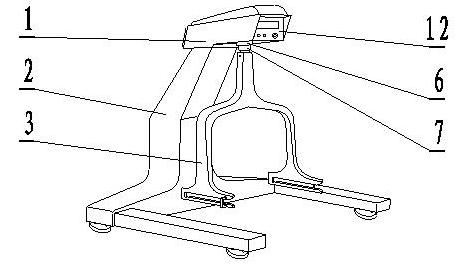

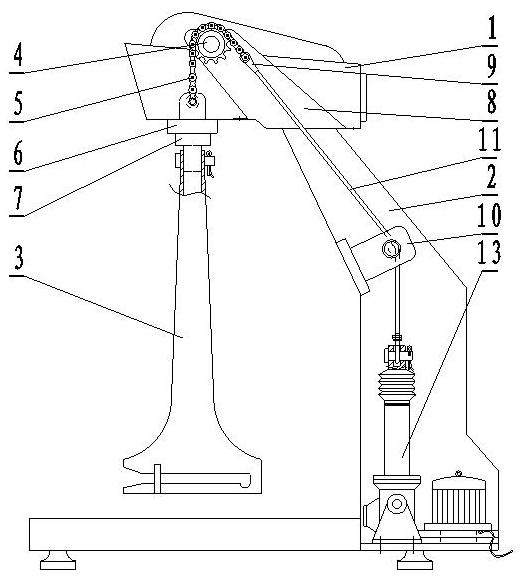

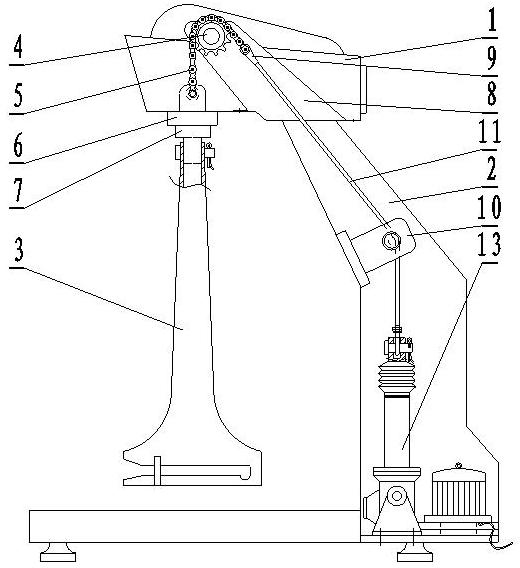

Special electronic balance for electric lifting hopper truck

InactiveCN102410867AFast meteringSolving Metering ProblemsSpecial purpose weighing apparatusElectricityDisplay device

The invention discloses a special electronic balance for an electric lifting hopper truck. The special electronic balance consists of a balance head, a balance frame, a balance hook, chain wheels, chains, a sensor, a steel wire rope, a display device, an electric push rod component and the like, wherein the balance head is fixed on the balance frame; the electric push rod component is fixed on the bottom surface in the hollow balance frame; the electric push rod component is connected with the chains by the steel wire rope through a wheel frame device and a connector; the chains are connected with a connecting device through the chain wheels fixed on a chain wheel bracket in the balance head; the connecting device is connected with a pin shaft of the balance hook through the sensor; and the display device arranged on the front surface of the balance head is electrically connected with the sensor. The chain wheels and the chains form a double-row structure in which two sets of same chain wheels and chains are abreast with each other for transmission. As an electric push rod is used for lifting, double rows of chain wheels and double rows of chains are used for transmission, the weight sensor is used for metering, and the special hopper truck is used, the special electronic balance is practical, stable and accurate; and therefore, metering of semi-finished products during production of raw and fresh meat product processing enterprises can be realized.

Owner:张百冬

Nurse watch

InactiveCN101756773AAccurate measurementFast meteringElectromechanical unknown time interval measurementElectric unknown time interval measurementSpeech soundEmbedded system

The invention discloses a nurse watch which comprises a watch case, an electronic movement arranged inside the watch case, a reminder connected with the movement, and a power supply used for supplying power for the reminder, wherein the watch case is provided with a key used for triggering the movement to count down; the reminder can be a voice device or a vibrating device; when in use, the corresponding key is pressed, the movement begins to count down, and drip speed or heartbeat can be counted at the same time; the reminder makes a sound or sends out a vibration signal when a timing cycle is finished; and therefore, a nurse only needs to calculate the drip speed and the heartbeat and can know the used time without looking at the watch, thus effectively improving the accuracy and the speed of calculation.

Owner:胡令东

Partition stock bin used for multi-bucket scale

InactiveCN108750156AQuantitative packagingFast weighingPackaging automatic controlSolid materialSurface mountingEngineering

The invention discloses a partition stock bin used for a multi-bucket scale. The partition stock bin used for the multi-bucket scale comprises a stock bin body and a weighing sensor; support columns are installed on two sides of the stock bin body; a controller is installed above an L-type mounting board; an electric push rod is installed on one side of the bottom end of the L-type mounting board;a first partition board is clamped on the surface of a first sliding groove; a second partition board is installed on the surface of a second sliding groove; a first discharging outlet is formed in the bottom of the stock bin body; a first slide board is installed inside the first discharging outlet; the weighing sensor is installed inside the first slide board; discharging pipes are installed atthe bottoms of the first discharging outlet, a second discharging outlet and a third discharging outlet; and a pneumatic valve is installed on the surface of a discharging pipe. By arranging the structure of the weighing sensor, the pneumatic valve, an electric butterfly valve, the electric push rod, the controller, the first partition board and the second partition board, the problems that automatic weighing mechanisms are absent and the modes of partition stock bin bodies are too simplex are solved.

Owner:SUZHOU WEIPAN INTELLIGENT TECH

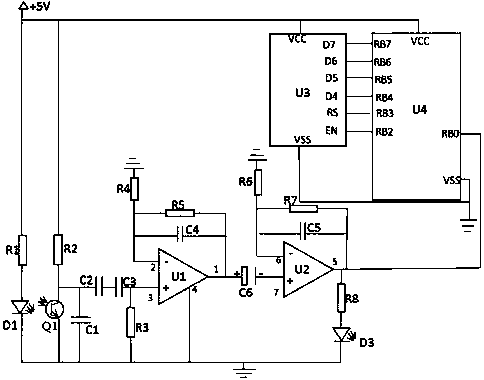

Cardiotachometer

InactiveCN107865649ASimple structureQuick responseOne-port networksAmplifier combinationsMicrocontrollerProcess module

The present invention proposes a heart rate meter, including a signal acquisition circuit, a filter circuit, an operational amplifier circuit, a processing module U4, and a display module U3; the signal acquisition circuit includes an infrared emitting tube D1, an infrared receiving tube Q1, and a resistor R1; the filter circuit includes a resistor R2 , R3, capacitors C1, C2, and C3; the operational amplifier circuit includes operational amplifier U1, operational amplifier U2, resistors R4, R5, R6, R7, capacitors C4, C5, and C6; the processing module U4 is a PIC16F84 microcontroller; the display module U3 is an LCD1602 Display modules. Compared with the prior art, the advantages and positive effects of the present invention are: the circuit structure is simple, the response is fast, the cost is low, the operation is stable, the heart rate of the subject can be measured quickly and conveniently at low cost, and it is easy to carry; The integrated anti-interference structure can filter out most of the high-frequency interference and ensure the reliability of the measurement results.

Owner:邵立新

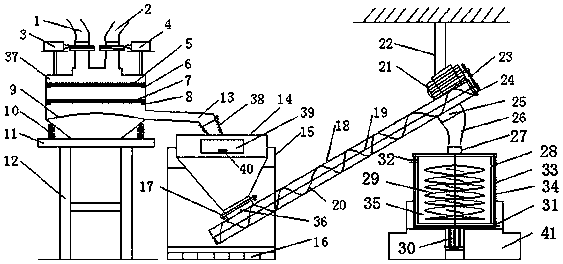

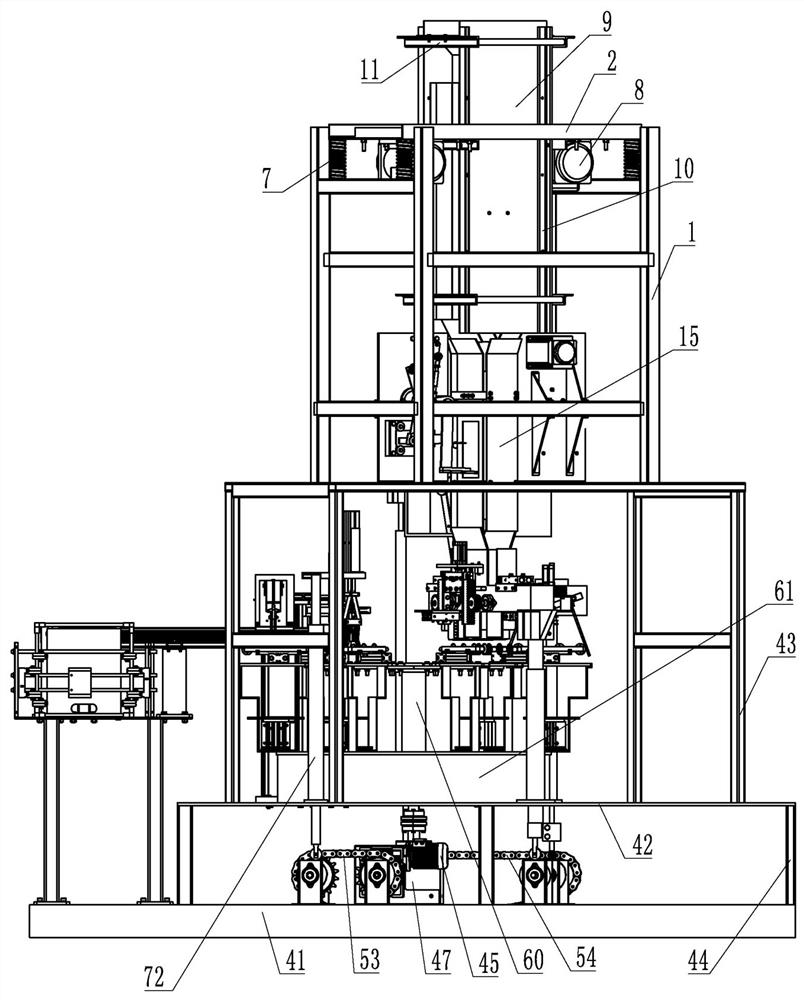

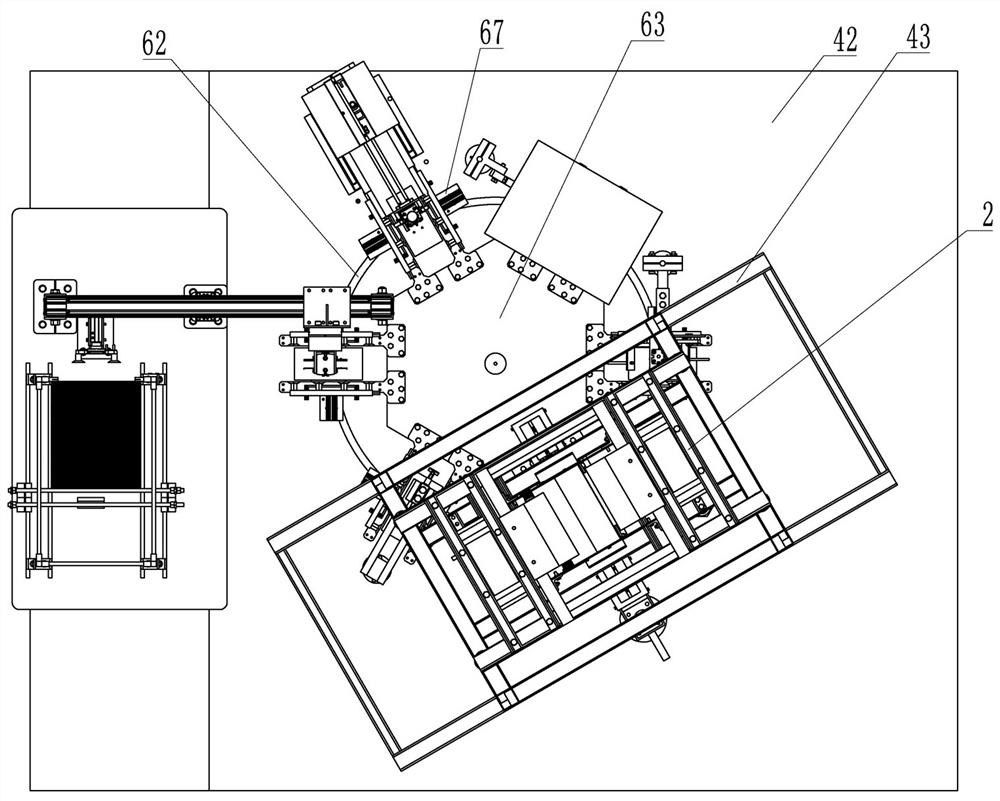

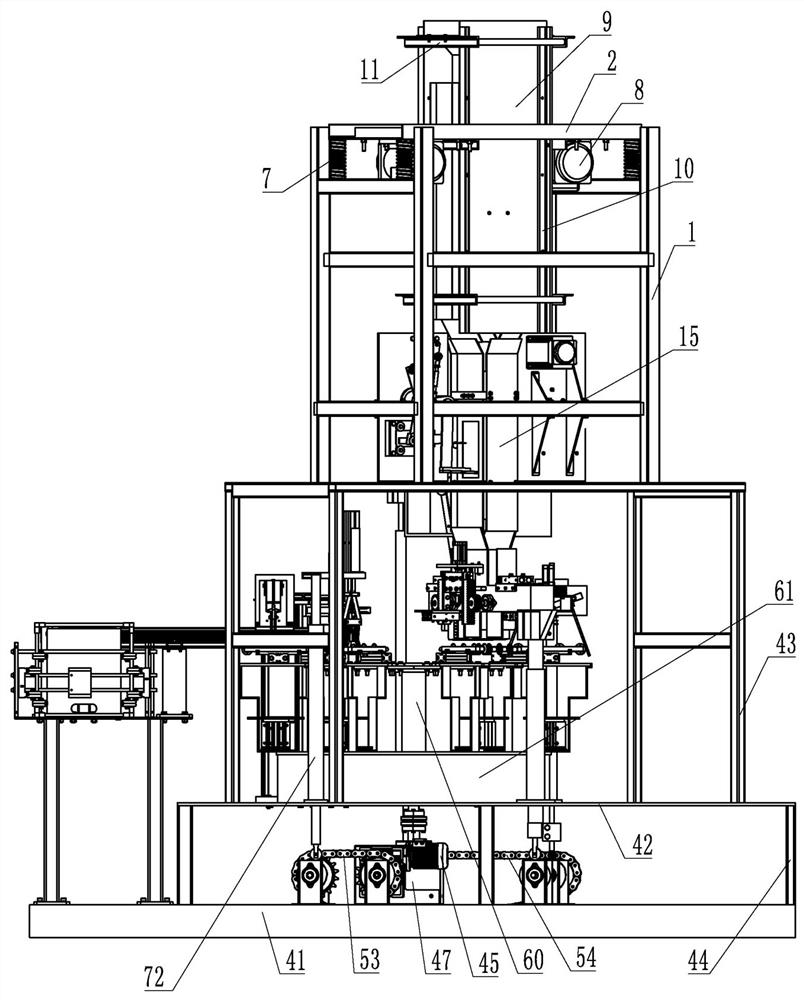

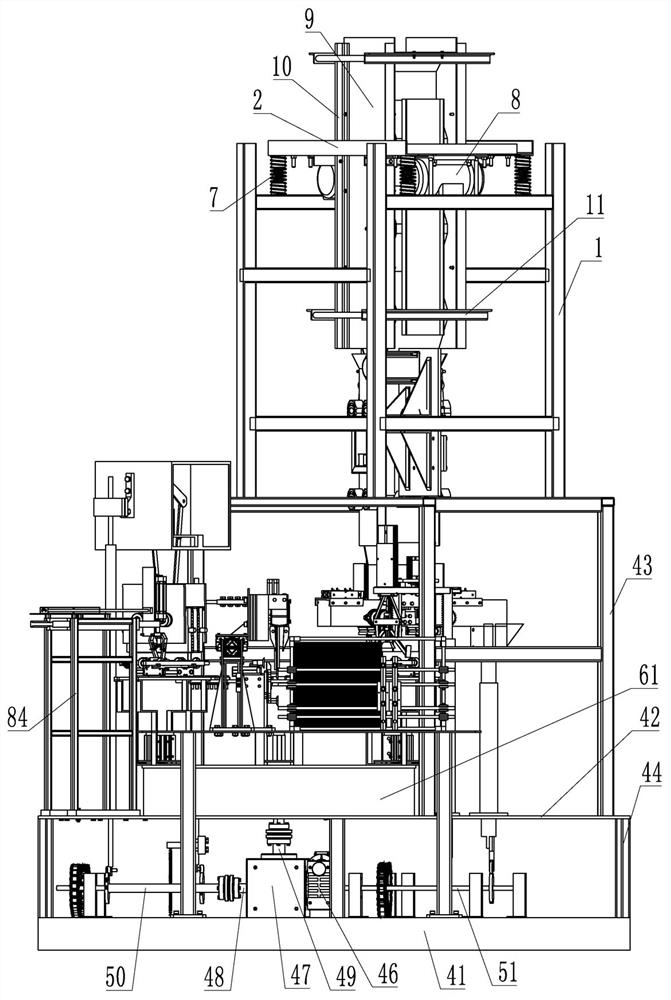

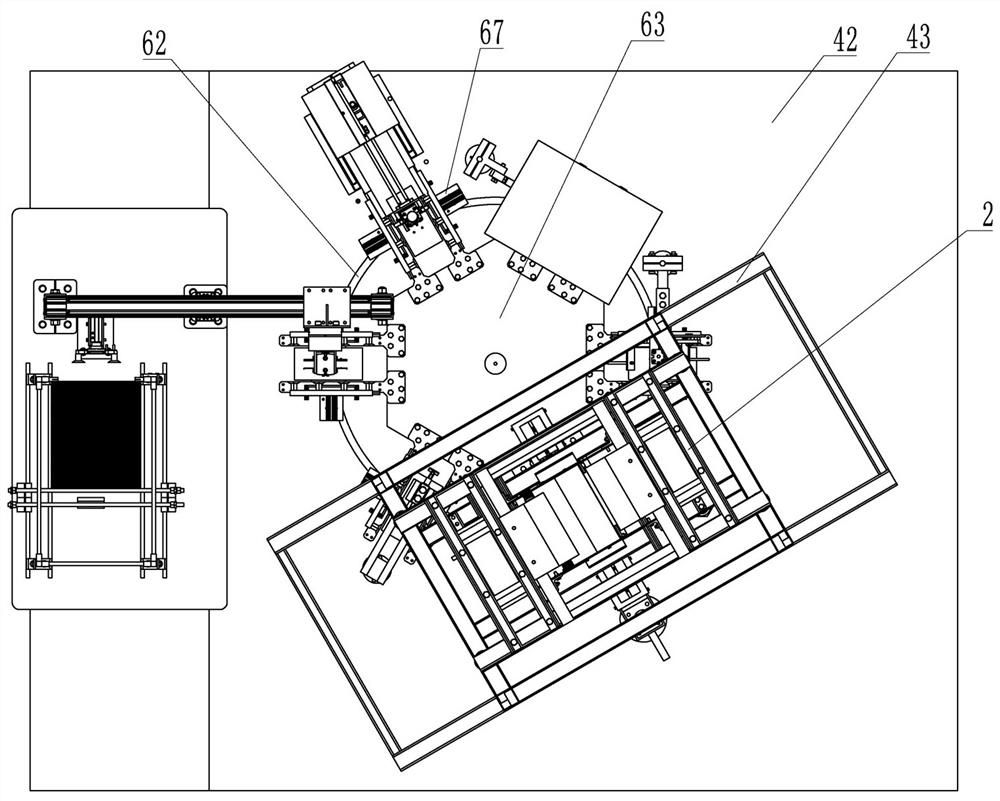

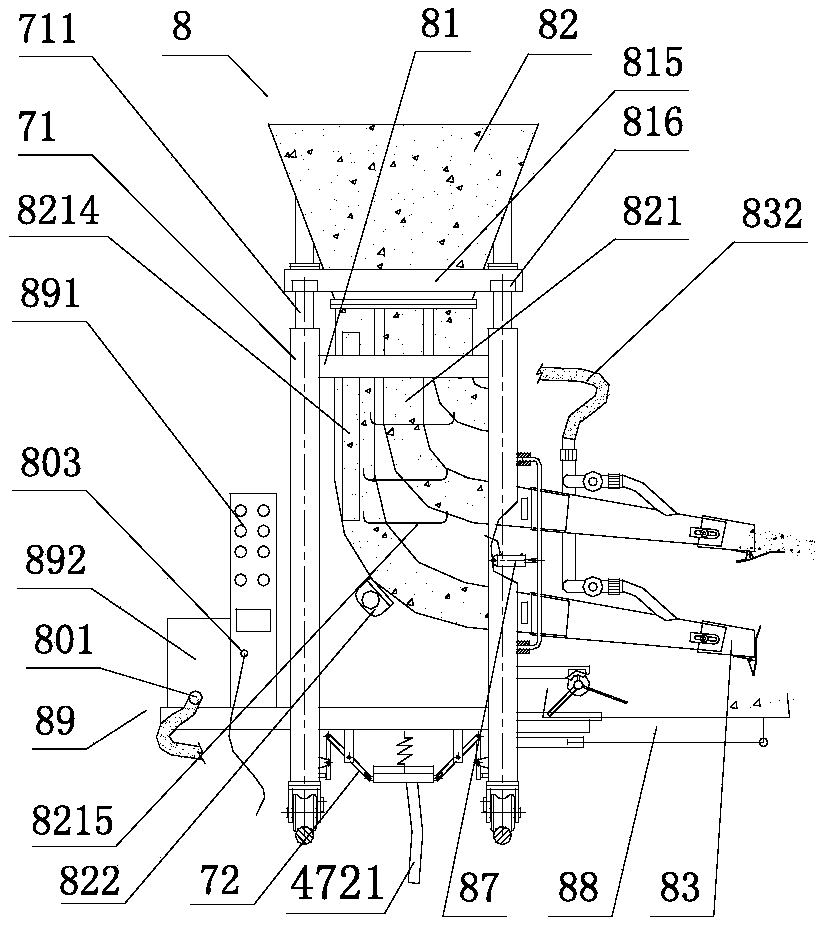

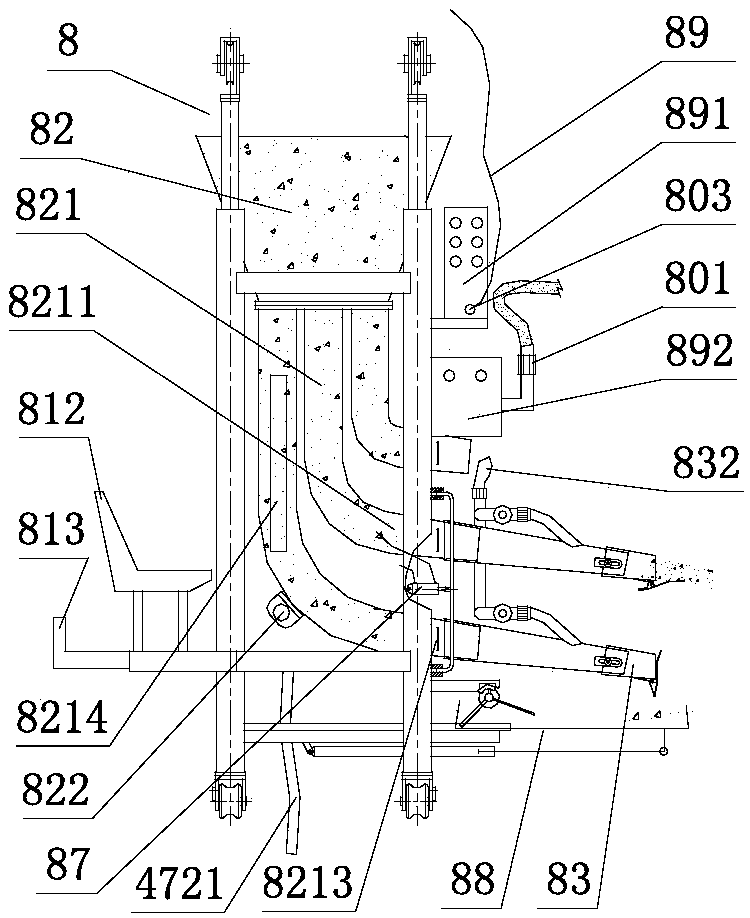

High-speed metering and automatic rotation packaging machine for fine dried noodles

ActiveCN113479377AHigh degree of automationAccurate measurementWrapper twisting/gatheringRod-shaped articlesProcess engineeringIndustrial engineering

The invention discloses a high-speed metering and automatic rotation packaging machine for fine dried noodles. The packaging machine comprises a base, a working platform, a power module, a supporting frame, a rotation module, a bag supply module, a bag opening and blowing module, a falling and filling module, a shaping module, a heat sealing module, a bag unloading module and a fine dried noodle high-speed metering module, wherein the rotation module is arranged above the working platform, the bag supply module, the bag opening and blowing module, the falling and filling module, the shaping module, the heat sealing module and the bag unloading module are arranged above the rotation module in a circumferential array mode according to a packaging procedure, the fine dried noodle high-speed metering module is arranged over the falling and filling module through a supporting frame, and six bag opening mechanisms and six bag supporting mechanisms are arranged on the rotation module in a circumferential array mode. According to the packaging machine, fine dried noodle packaging is continuously and repeatedly carried out one by one through the six bag opening mechanisms on the rotation module, the automation degree is high, metering feeding is carried out in the mode that rough metering feeding and fine metering feeding are combined, metering is accurate and rapid, and the packaging efficiency can be effectively improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

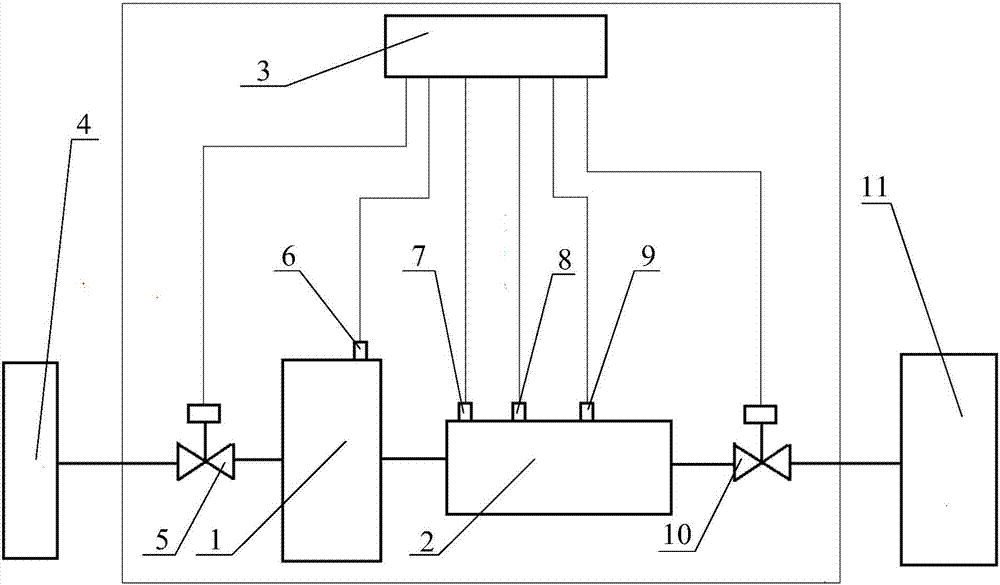

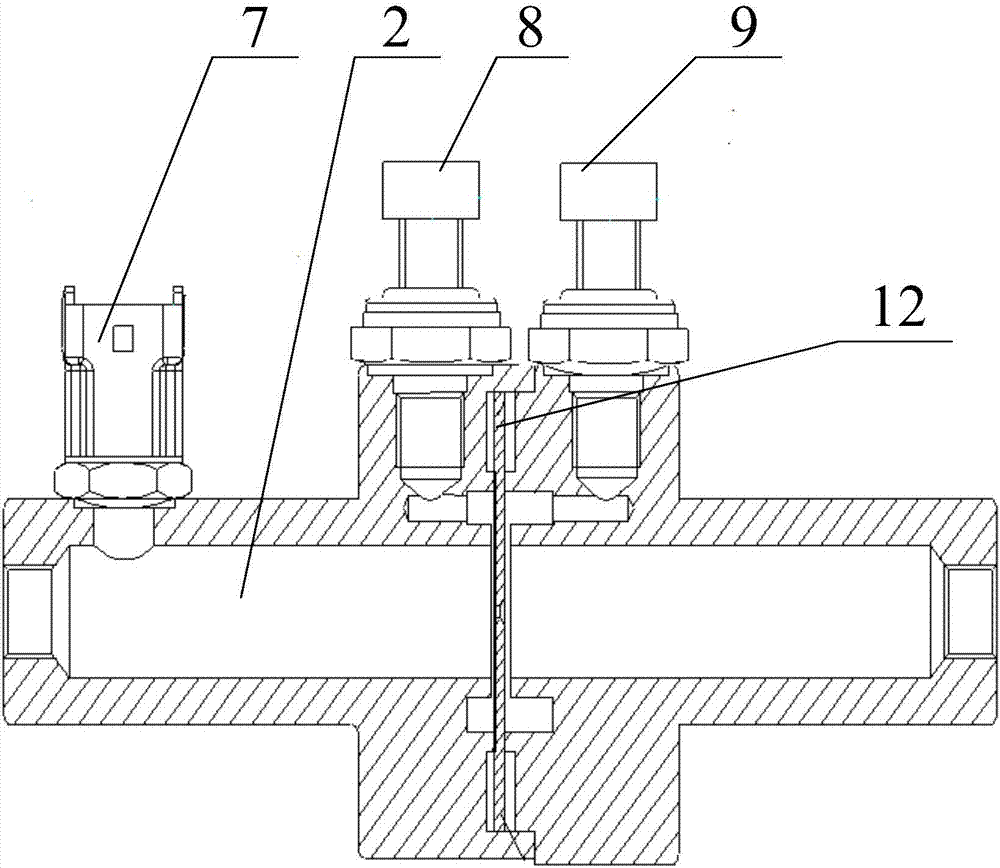

Ammonia gas filling metering device and ammonia gas filling metering method for slow ammonia gas filling and rapid ammonia gas filling

PendingCN107084766AFast meteringVolume meteringIndirect mass flowmetersProcess engineeringStress sensors

The invention discloses an ammonia gas filling measuring device and is used for ammonia gas filling metering in a solid ammonia gas storage tank. The ammonia gas filling measuring device comprises a first valve body, a unit tank, a flow acquisition device, a second valve body and a controller which are sequentially communicated; the first valve body is communicated with a gas source; the second valve body is communicated with the solid ammonia gas storage tank; a temperature sensor is arranged on the unit tank; a throttling element, a gas temperature sensor, a front-end pressure sensor and a rear-end pressure sensor are arranged on the flow acquisition device; the controller comprises a signal acquisition device, a computing device and a control device; the signal acquisition device is in signal connection with the temperature sensor, the gas temperature sensor, the front-end pressure sensor and the rear-end pressure sensor simultaneously; the control device is connected with the first valve body and the second valve body. Through metering at the ammonia gas filling stage, the quick metering of the quality of filled ammonia gas in the solid ammonia gas storage tank is realized. The invention further discloses an ammonia gas filling metering method for slow ammonia gas filling and rapid ammonia gas filling based on the ammonia gas filling measuring device.

Owner:科林蓝泰环境科技(长春)有限公司

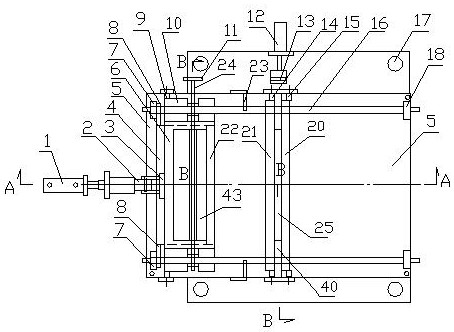

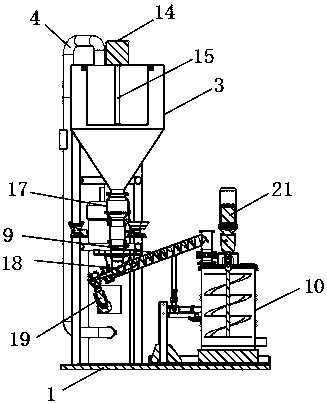

Nondestructive numerical control hydraulic machine for powder strip

PendingCN112373088AWon't penetrateSo as not to damagePress ramNumerical controlStructural engineering

The invention discloses a nondestructive numerical control hydraulic machine for a powder strip. The machine comprises a machine frame, a hydraulic system, a controller and a feeding mechanism assembled on the machine frame, wherein an upper die plate, a middle die plate and a lower die plate are arranged on the machine frame, the upper die plate, the middle die plate and the lower die plate are movably connected through stand columns, a working plate is arranged on the middle die plate, guiding shafts are oppositely arranged on the working plate, the two ends of each guiding shaft are fixedlyarranged on supporting seats, shaft seats are movably arranged on the guiding shafts, a storage box capable of moving leftwards and rightwards in a horizontal direction of the working plate is fixedly connected between the shaft seats, a storage cavity is formed in the storage box, and an inserting plate is arranged between the lower bottom face of the storage box and the working plate. Accordingto the machine, it can be guaranteed that powder does not permeate into the surface of the working plate, the surface of the working plate and a die are not damaged, the service life of a model is prolonged, the quality of formed and pressed products is facilitated, and the powder can be accurately and rapidly injected into a forming cavity through the rotation number and rotation time and by using metering based on size, rotation number and time.

Owner:黄静

Breeding feeding system with elevator lifting mechanism and overturn-preventing device

InactiveCN109418185ASmooth liftIncrease stiffnessClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses a breeding feeding system with an elevator lifting mechanism and an overturn-preventing device. The system comprises a breeding pool, a culture cabinet, a crane and a feeding machine, wherein workshop tracks are pressed by wheel treads of a large vehicle running device of the crane so as to achieve running of the crane, the two workshop tracks are arranged on the floor of aworkshop in which the breeding pool is arranged, and the culture cabinet is arranged in the breeding pool; the feeding machine is provided with a leaked material receiving device for collecting feedscattered in the feeding process and automatically scraping the scattered feed into a collection box, the feeding machine is connected to a trolley device of the crane through the lifting mechanism, and runs with the crane, and the trolley device is provided with the overturn-preventing device; and the lifting mechanism includes a folding link elevator, the crane is used for lifting the culture cabinet to the pool surface of the breeding pool, and the feeding machine is used for performing quantitative feeding of the lifted culture cabinet through high-pressure gas.

Owner:福州市晋安区澳杰新自动化设备有限公司

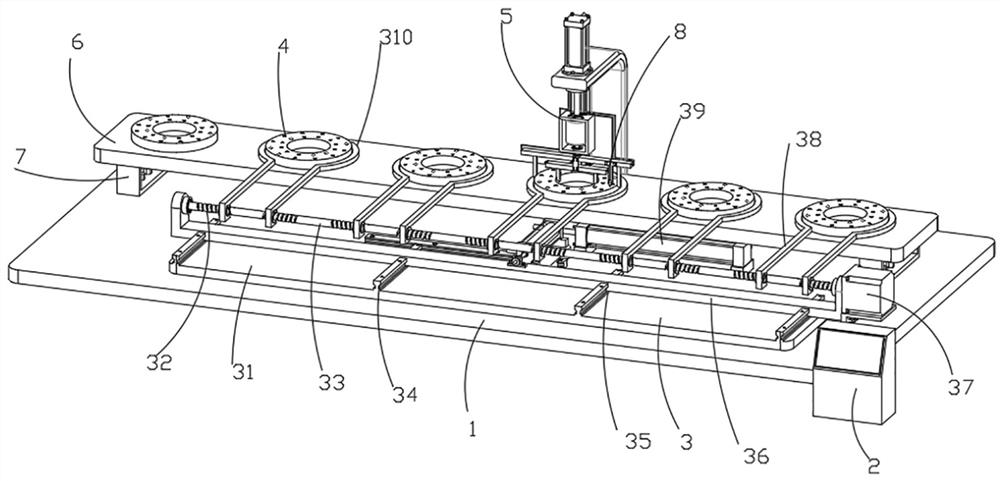

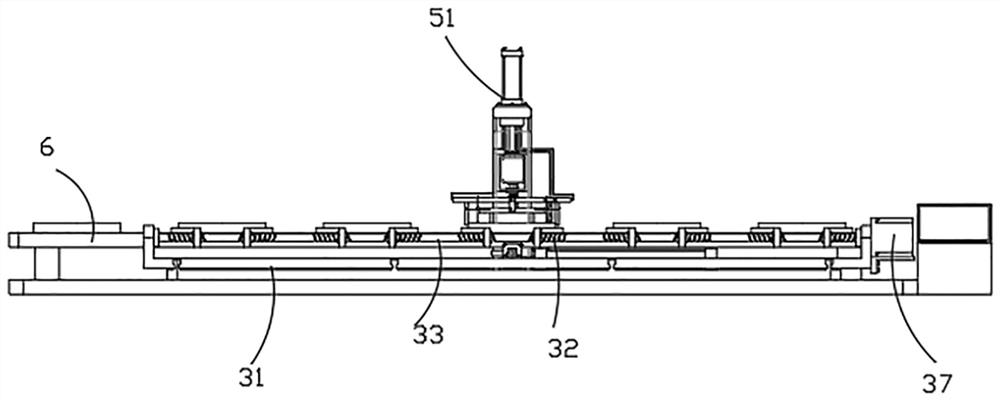

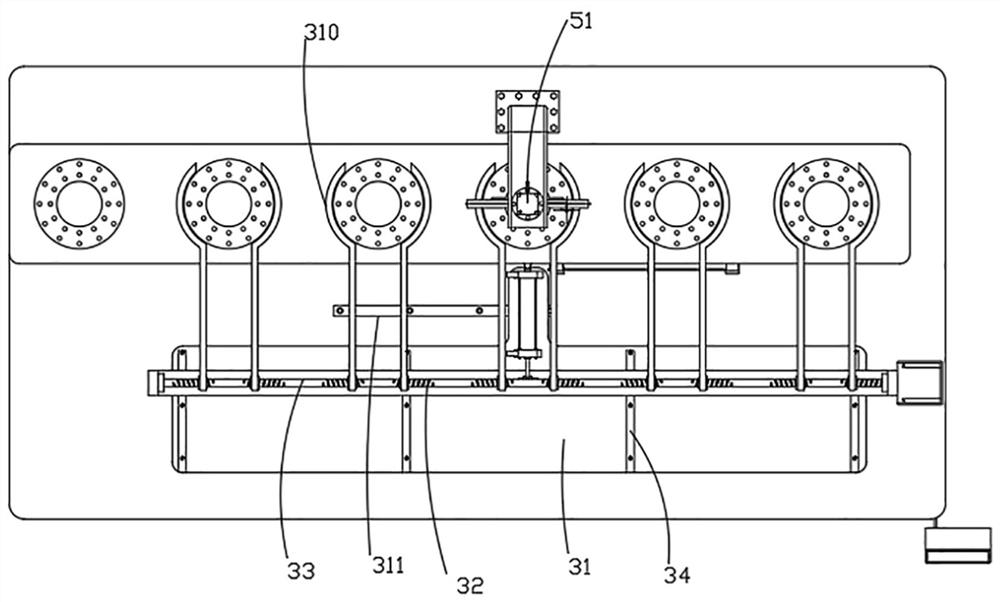

Tool and method for measuring lengths of inner diameter and outer diameter of brake disc

ActiveCN113624119AEasy to moveRealize multi-point measurementWork holdersUsing electrical meansBrakeStructural engineering

The invention provides a tool and method for measuring the lengths of the inner diameter and the outer diameter of a brake disc. According to the technical scheme, the tool comprises a base, a control box and the brake disc; a supporting assembly is arranged at the top of the rear side of the base, brake discs are evenly placed on the supporting assembly, the base is provided with a measuring structure used for measuring the inner diameter and the outer diameter of the brake discs on the rear side of the supporting assembly and provided with a translation structure used for translating the brake discs on the front side of the supporting assembly, and the electric control driving end of the control box is connected with the translation structure and the electric control driving end of the measuring structure. The measuring method comprises the following specific steps that 1, the brake discs are placed on the supporting assembly; 2, the brake discs on the supporting assembly are horizontally moved to the position under the measuring structure in sequence through the translation structure; and 3, a third air cylinder of the measuring structure drives an outer diameter length measuring structure and an inner diameter length measuring structure to move; The tool has the advantages that multi-point measuring is achieved, measuring tools do not need to be adjusted frequently, time and labor are saved during measuring of the inner diameter and the outer diameter of the brake disc, and rapid measuring is facilitated.

Owner:山东裕东汽车零部件有限公司

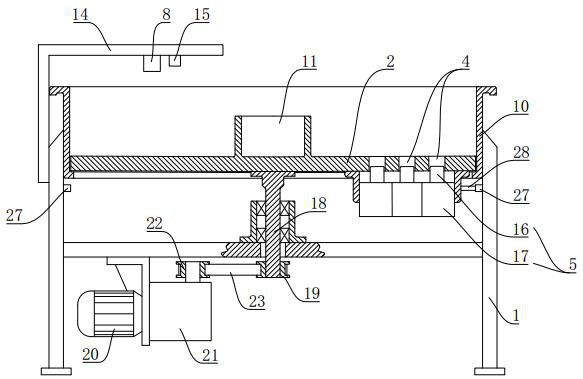

Automatic particle counting device for particle materials

The invention discloses an automatic particle counting device for particle materials. The device comprises a rack, a rotating tray driven by a power device is mounted on the rack, a plurality of single particle holes are formed in a material carrying area of the rotating tray, and an ejection device is arranged at the bottom of each single particle hole; a defective product unloading area and a finished product unloading area are arranged at the left side and the right side of the rotating tray on the rack respectively, a camera used for collecting images of the material carrying area is installed at the position, over the defective product unloading area, of the rack, and the signal output end of the camera and the control ends of the ejection devices are both electrically connected with a controller; and the controller receives image information of the camera in real time and compares the image information with standard image information to judge whether particles in the single particle holes are intact or not so as to control the ejection devices to act in the defective product unloading area or the finished product unloading area. The device can accurately meter the quantity of output particles, can effectively identify and separate unqualified invalid tablets such as half tablets and broken tablets, and has the advantages of high particle counting speed and high yield.

Owner:SHANDONG SMA PHARMATECH CO LTD

High-speed measuring automatic rotary packaging machine for noodles

ActiveCN113479377BHigh degree of automationAccurate measurementWrapper twisting/gatheringRod-shaped articlesEngineeringPackaging machine

High-speed metering automatic rotary packaging machine for noodles, including base, working platform, power module, support frame, rotary module, bag supply module, bag opening and blowing module, blanking and filling module, shaping module, heat sealing module, bag unloading module and The high-speed measuring module for noodles, the rotary module is rotated and arranged above the working platform, and the bag supply module, bag opening and blowing module, blanking and filling module, shaping module, heat sealing module and bag unloading module are arranged on the rotary module in a circular array according to the packaging process. Above, the high-speed measuring module for hanging noodles is arranged directly above the blanking and filling module through the support frame, and six bag opening mechanisms and six bag holding mechanisms are arranged in a circular array on the rotary module. The present invention continuously and repeatedly carries out the noodle packaging one by one through the six bag opening mechanisms on the rotary module, and has a high degree of automation. efficiency.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

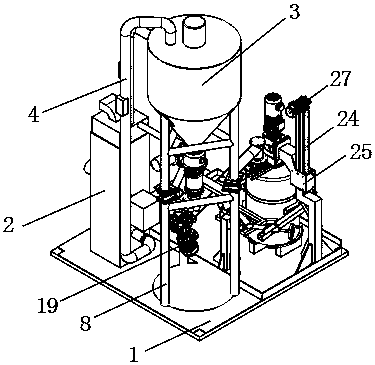

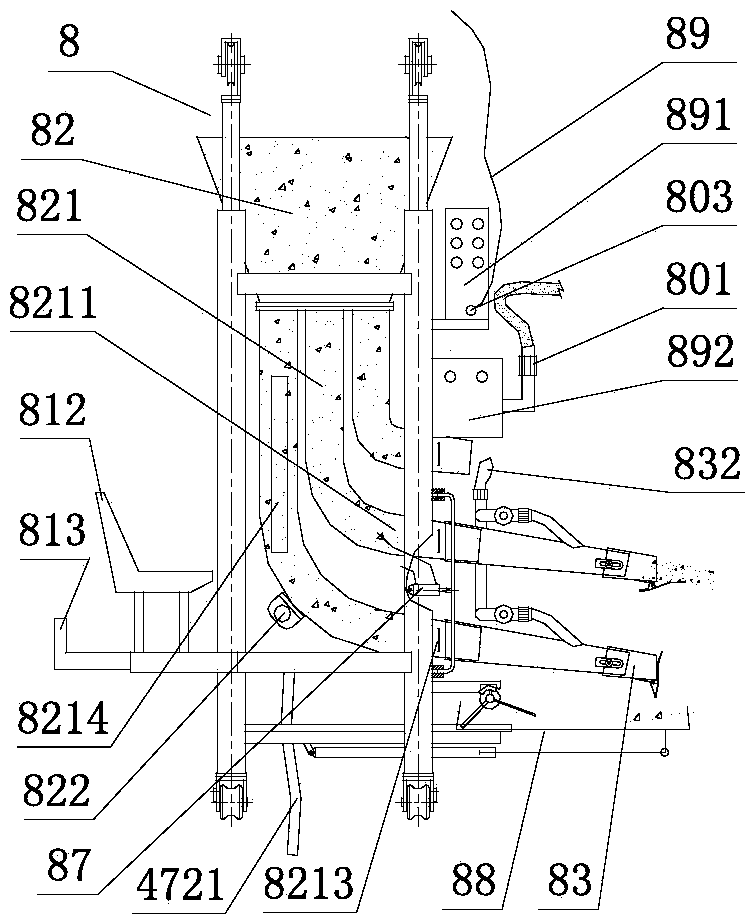

Feeder with elevating control mechanism and multiple material spray pipes

InactiveCN108967311AFree from pollutionAdd in timeClimate change adaptationPisciculture and aquariaEngineeringHigh pressure water

The application discloses a feeder with an elevating control mechanism and multiple material spray pipes. The feeder comprises a frame, a material bin, hoppers, material spray pipes, electromagnetic valves, an air pressure tank, vibrators and an elevating control mechanism. The frame comprises an air pressure column. The material bin is connected with a piston rod of the air pressure column abovethe frame. The elevating control mechanism below the frame controls the piston rod to perform elevating movement. The multiple hoppers are connected below the material bin. The bottom of each hopper is equipped with a material discharge pipe connected with a material spray pipe. The multiple material spray pipes are arranged to be one line or multiple lines. Outlet directions of the pipes are slightly and downwardly oblique. The water spray pipes are equipped with water flushing pipes. The water flushing pipes are connected with a pipeline of the air pressure tank and connected with the electromagnetic valves. An air bag of the air pressure tank is arranged in a steel tank body. the air bag can generate and store high-pressure water. The vibrators are connected to connecting bodies of themultiple hoppers or the outer wall of the material bin. The feeder takes high-pressure water as a power so that fixed amount of fodders in the water spray pipes is delivered out.

Owner:张达英

Oil field multiphase metering mixed transportation device and use method thereof

InactiveCN110905482AFast meteringEasy to measureSurveyFluid removalThermodynamicsVapor–liquid separator

The invention discloses an oil field multiphase metering mixed transportation device. The oil field multiphase metering mixed transportation device comprises a bottom plate, wherein a gas-liquid separator is fixedly arranged on the upper surface of the bottom plate, the gas-liquid separator communicates with a mixing bin through a liquid output pipeline and a gas output pipeline, the liquid outputpipeline and the gas output pipeline are respectively provided with a liquid flowmeter and a gas flowmeter, the bottom of the mixing bin is connected with a connecting channel, the bottom of the connecting channel is connected with a material pushing cylinder, the bottom plate is provided with a mixing cylinder, one end of the material pushing cylinder is connected to the upper surface of a sealing cover plate, a first mixing blade is connected to the end part of an output shaft of a second motor, and a second mixing blade is arranged on a mixing rod. The oil field multiphase metering mixed transportation device achieves fast and convenient metering, can rapidly mix liquid and gas, and achieves full mixing after the liquid and the gas are stirred and mixed for many times, so that subsequent conveying is facilitated, and the working efficiency is effectively improved; and the mixing bin is convenient to disassemble and assemble, so that the mixing bin is quickly cleaned.

Owner:王国利

Feeding machine with spraying pipe adjustment device and leaked material receiving device

InactiveCN108967298AConvenient choiceConsistent and accurate feedingClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses a feeding machine with a spraying pipe adjustment device and a leaked material receiving device. The feeding machine comprises a frame, a stock bin, a hopper, a spraying pipe,a spraying pipe lateral adjustment device, the leaked material receiving device, and a material water flushing system. The stock bin is connected to the upper part of the frame, and the hopper is connected in a vertical direction below the stock bin. The bottom of the stock bin is provided with a lateral discharge pipe. The spraying pipe is connected with the discharge pipe through the spraying pipe lateral adjustment device, and the spraying pipe lateral adjustment device is provided with a control mechanism which is driven by an air cylinder, or a hydraulic cylinder or an electric push rod to operate, and wherein the control mechanism can control the connected spraying pipe to make lateral telescoping motion. The spraying pipe is provided with an adjustable metering mouth, and the adjustable metering mouth can adjust the metering capacity. The frame is provided with an operating platform and a placing platform. The leaked material receiving device is disposed below the frame, and cancollect the fodder scattered in the feeding process. The feeding machine takes the high-pressure water generated by the material water flushing system as the power to throw the quantitative fodder inthe spraying pope to the outside.

Owner:张达英

An image-based white blood cell counting method and system

ActiveCN108257124BAccurate CountingImprove Segmentation AccuracyImage enhancementImage analysisWhite blood cellCell region

The invention relates to an image-based white blood cell counting method and system, wherein the method includes the steps of collecting blood sample images, removing image noise, roughly segmenting cell regions, obtaining the number of cohesive cells and obtaining the total number of white blood cells. Because the present invention adopts the white blood cell automatic segmentation technology of self-adaptive fuzzy clustering technology, the white blood cell segmentation accuracy is higher, and the adhesion cell location segmentation method based on the three-dimensional curved surface can quickly identify the adhesion cells with inconspicuous area and chain code characteristics, adhesion cells The location counting segmentation is more accurate, so that the number of white blood cells can be counted more accurately.

Owner:JIANGSU KONSUNG BIOMEDICAL TECH

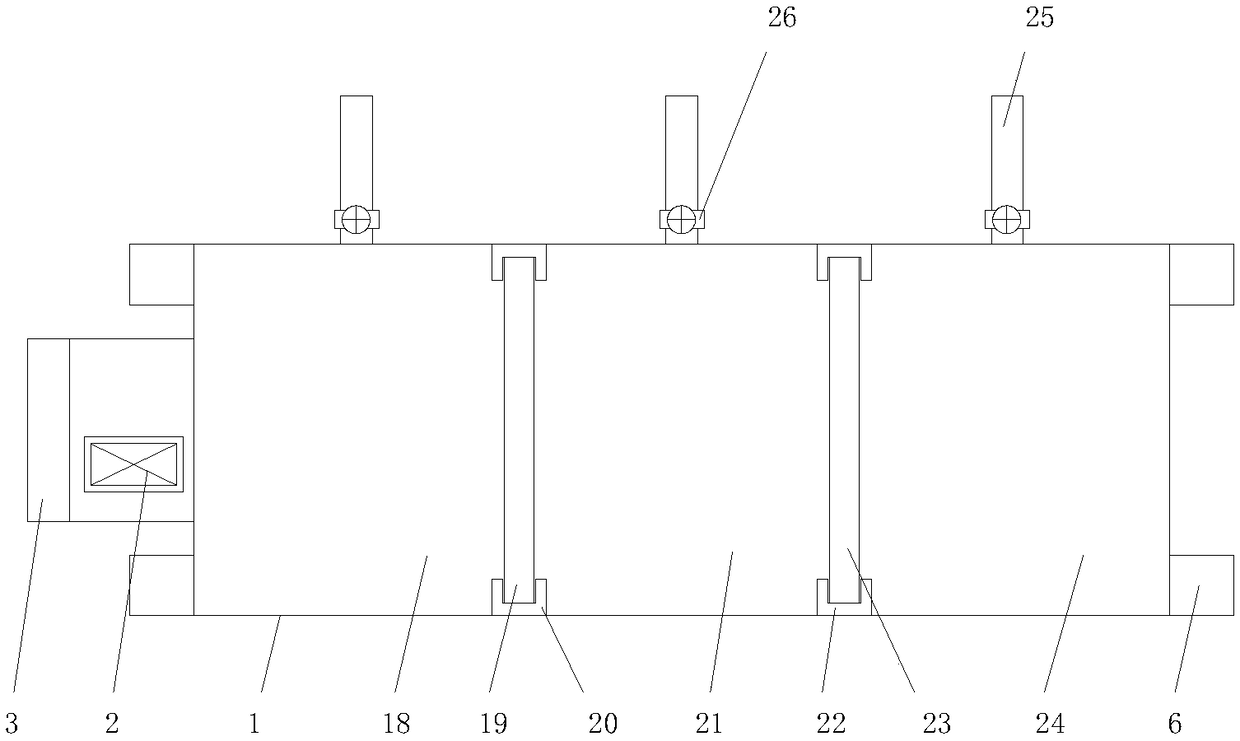

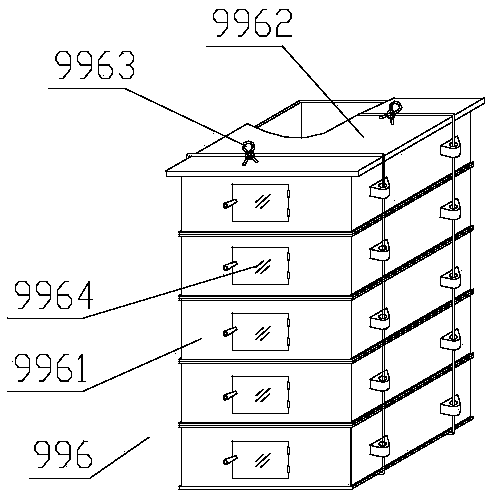

Abalone culture feeding system with operating platform and weighing device

InactiveCN109452209ASmooth liftIncrease stiffnessClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses an abalone culture feeding system with an operation platform and a weighing device, which comprises a culture pond, a culture cabinet, a crane and a feeding machine. The wheeltread of one large vehicle running device in the crane is pressed on a workshop track on the ground of the workshop where the culture pond is positioned to run, the wheel tread of the other large vehicle running device is pressed on the workshop track above a bearing rail beam to run, and the bearing rail beam is connected with a bracket of a workshop upright post; the culture cabinet is arrangedin the culture pond, the culture cabinet is provided with a plurality of culture boxes, and the culture boxes are provided with swing doors; the feeding machine is provided with an operation table; the feeding machine is connected on the crane through a lifting mechanism and runs along with the crane, and the lifting mechanism comprises a folding connecting rod elevator; the crane is provided withthe weighing device, the crane lifts the culture cabinet onto the pond surface of the culture pond and can display the weight of the culture cabinet on the weighing device, and the feeding machine quantitatively feeds the raised culture cabinet through high-pressure gas.

Owner:福州市晋安区澳杰新自动化设备有限公司

Feeding machine with metering mouths and leaked material receiving device

InactiveCN108967301AEffective control of feed sizeEffective speed controlClimate change adaptationPisciculture and aquariaAgricultural engineeringHigh pressure water

The invention discloses a feeding machine with metering mouths and a leaked material receiving device, and the feeding machine comprises a frame, a stock bin, a hopper, spraying pipes, an air pressuretank, a water pump, and the leaked material receiving device. The stock bin is fixedly connected to the upper part of the frame, and one or more hoppers are connected in the vertical direction belowthe stock bin. The bottom of each hopper is provided with a lateral discharge pipe. One or more spraying pipes are connected with the discharge pipes, and the spraying pipes are arranged in one or multiple columns, wherein the outlets of the spraying pipes are slightly horizontal. Each spraying pipe is provided with a flushing pipe and one metering mouth, wherein each metering mouth is a tubular body, and the outlet of each metering mouth is provided with a sealing gate. The leaked material receiving device is connected below the frame, and can collect the fodder scattered in a feeding process, and can automatically scrape the scattered fodder into a collection box. The air pressure tank and the water pump are connected to the frame, wherein the water pump supplies water to the air pressure tank, and the air pressure tank generates and stores high-pressure water. The feeding machine takes the high-pressure water as the power to throw the metered fodder in the metering mouth to the outside.

Owner:张达英

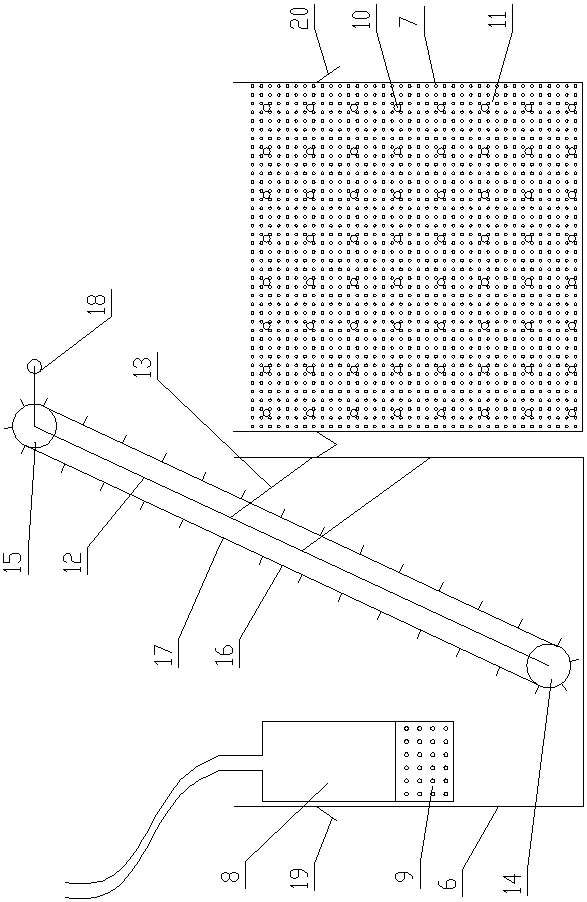

Measuring system and method for hydraulic reaming to relieve pressure, increase permeability and increase coal expansion

ActiveCN105464596BAchieve separationAccurate measurementMining devicesConstructionsCoal particleHigh pressure

The invention relates to a metering system and method for hydraulic reaming pressure-relief permeability-enhancing reaming coal quantity. The system comprises tracks laid in a roadway, a tramcar moving along the tracks, a drilling machine and high-pressure pump system arranged in the roadway, a slurry colleting barrel and a filtering barrel arranged at one side of the slurry colleting barrel. The drilling machine and high-pressure pump system is in transmission connection with a reaming drill rod and a drill bit, a water suction pump is arranged on the upper portion of one side of the slurry collecting barrel, and a manual coal conveying device is obliquely arranged in the slurry collecting barrel. The method includes the following steps that two filtering barrels are manufactured and machined; water coal slurry is collected and precipitated; water in the slurry collecting barrel is drained; coal particles are precipitated, and water is drained; coal slime and powdered coal are collected; the water and the coal are separated; the reaming coal quantity is calculated. The metering system can collect the coal slime fast, separate the water and the coal, accurately meter the reaming coal quantity, improve the operation environment, improve the metering precision, improve the accurate inspection of hydraulic reaming coal quantity, ensure the reaming pressure-relief permeability-enhancing effect and the gas pre-drainage effect and guarantee safety production of a coal mine.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com