Polyvinyl chloride powder ingredient stirring device

A technology of polyvinyl chloride powder and stirring device, which is used in solid separation, sieve, grille and other directions, can solve the problems of darkening, cracking and product quality reduction of polyvinyl chloride powder, so as to improve the environment in the workshop and improve the quality of the product. Ability to remove impurities and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

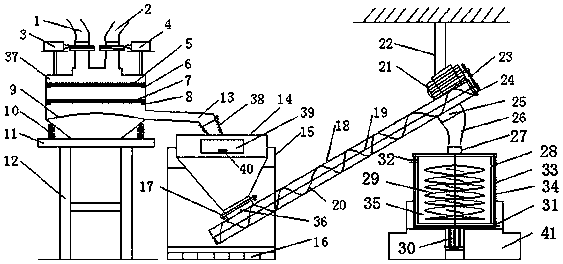

[0020] refer to figure 1 A polyvinyl chloride powder batching stirring device of the present invention will be further described.

[0021] A polyvinyl chloride powder batching stirring device is characterized in that: it comprises a vibrating screener 37, a collecting box 14, a conveyor 18, and a mixing bucket 35, and the upper end of the vibrating screener 37 is connected with a feeding pipe-1 and a feeding pipe Pipe two 2, the feed pipe one 1 and feed pipe two 2 are respectively provided with pneumatic valve one 3 and pneumatic valve two 4, and the upper end of the vibration filter 37 is provided with a bracket for fixing the pneumatic valve one 3 and pneumatic valve two. Valve two 4, the inner wall of the vibrating filter 37 is provided with a retaining ring one 6 and retaining ring two 8, and the upper ends of the retaining ring one 6 and retaining ring two 8 are respectively provided with a filter screen one 5 and a filter screen two 7, The lower end of the vibration fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com