Measuring system and method for hydraulic reaming to relieve pressure, increase permeability and increase coal expansion

A hydraulic reaming and metering system technology, which is applied to drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve problems such as unfavorable safety production, inaccurate inspection of coal expansion volume, and harsh operating environment, so as to ensure gas The effect of pre-pumping, ensuring the safe production of coal mines, and improving the safety level of mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

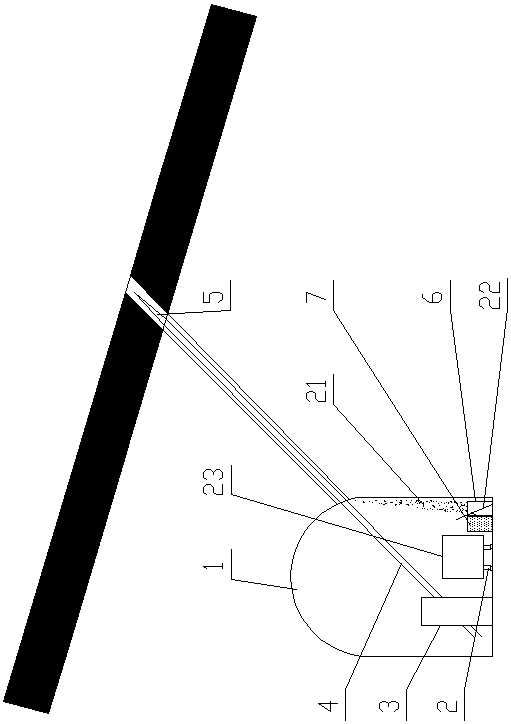

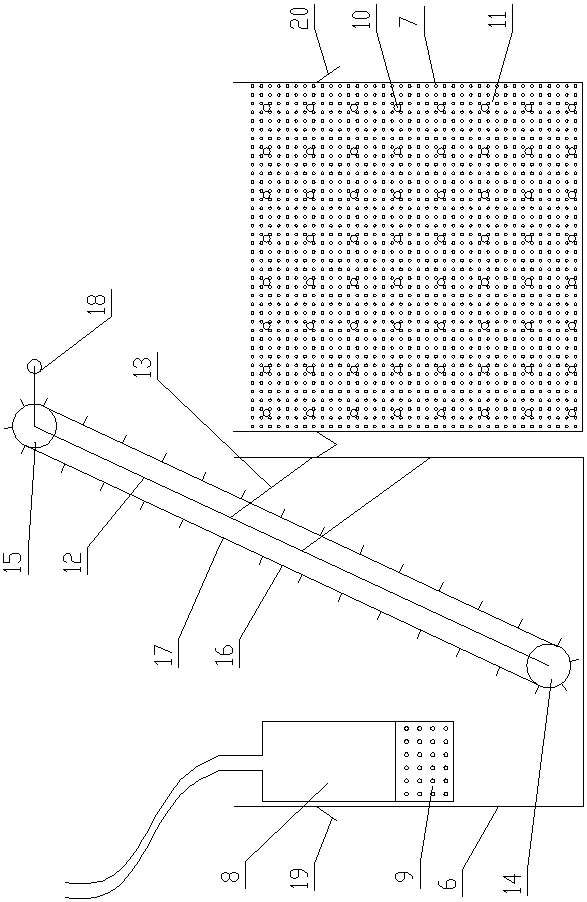

[0032] Such as figure 1 and figure 2 As shown, the metering system of hydraulic reaming pressure relief of the present invention to increase permeability and increase the amount of coal expansion includes the track 2 laid in the roadway 1, the mine car 23 traveling along the track 2 and the drilling rig and high-pressure pump arranged in the roadway 1 System 3, drilling rig and high-pressure pump system 3 are connected with a reaming drill pipe 4, and the end of the reaming drill pipe 4 is provided with a drill bit 5, and the drilling rig and high-pressure pump system 3 drives the reaming drill pipe 4 and the drill bit 5 to drill holes obliquely upward. It also includes a slurry collection bucket 6 and a filter bucket 7 located on one side of the slurry collection bucket 6. The top of the slurry collection bucket 6 and the filter bucket 7 is open, and the slurry collection bucket 6 is located directly below the hole of the drilled hole. The filter bucket 7 is located on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com