Nondestructive numerical control hydraulic machine for powder strip

A technology of long strips and hydraulic presses, applied in punching machines, presses, manufacturing tools, etc., can solve problems such as product quality decline, occupation of workshop space, inconvenience in large-scale production, etc., and achieve the effect of accurate measurement and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

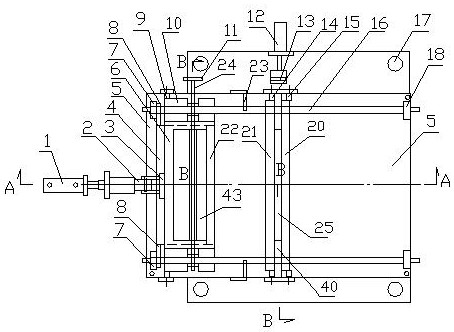

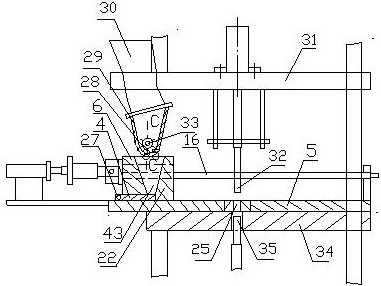

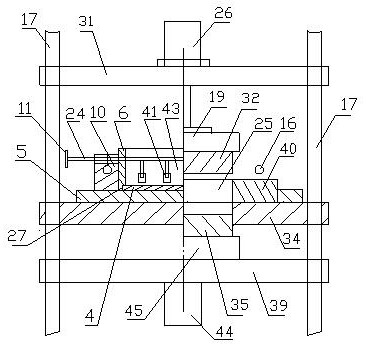

[0017] In the figure, a kind of powder strip non-destructive numerical control hydraulic press, it comprises frame, hydraulic system, controller and the feeding mechanism that fits on the frame, described frame is provided with upper template 31, middle template 34 and The lower formwork 39, the upper formwork, the middle formwork and the lower formwork are movably connected with four columns 17. The upper formwork is provided with an upper oil cylinder 26, and the upper oil cylinder 26 is connected with the upper punch seat 19 through a piston rod. The lower end of the punch seat 19 is connected with the upper punch 32, the lower template is provided with a lower oil cylinder 44, the lower oil cylinder is connected with the lower punch seat 45 through the piston rod, and the upper end of the lower punch seat is connected with the lower punch 35, The middle template is provided with a working plate 5, on which parallel guide shafts 16 are relatively arranged, and the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com