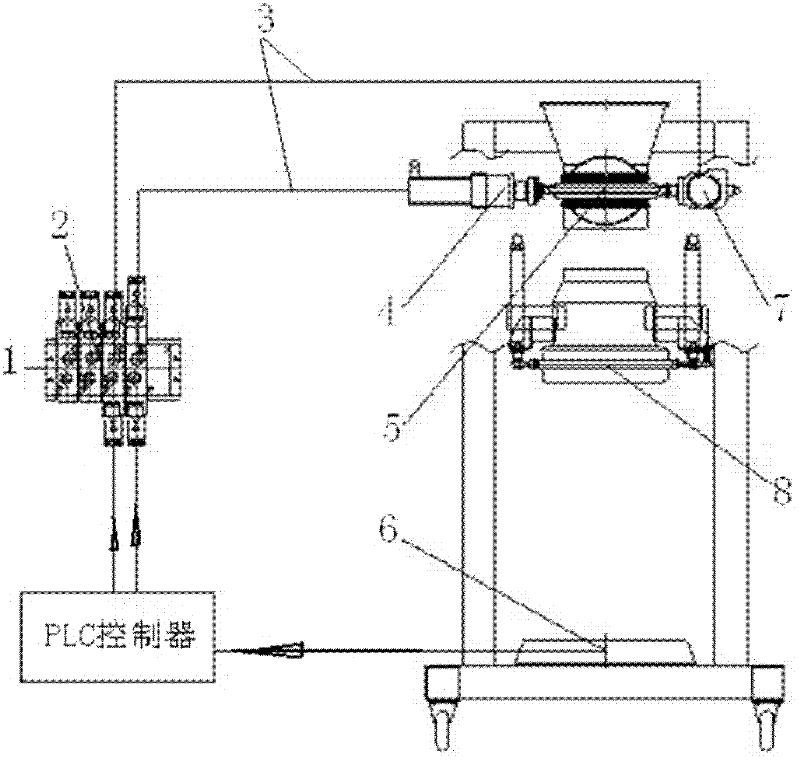

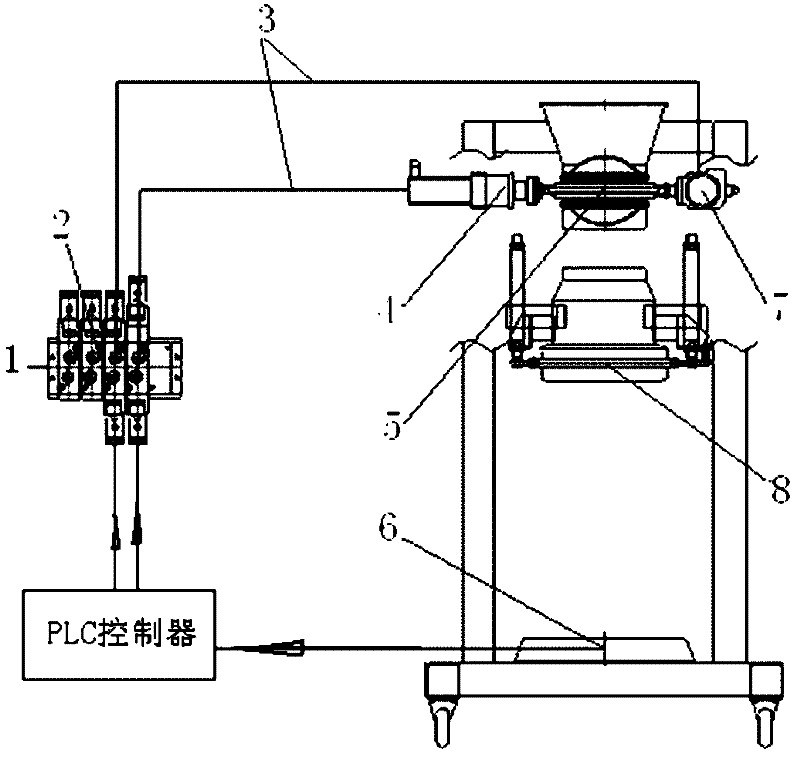

Feeding mechanism of metering racking machine

A sub-packaging machine and sub-packaging technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of large volume, inconvenient installation and maintenance, affecting the accuracy of measurement, etc., and achieve accurate measurement, convenient speed regulation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0019] All the aseptic dispensing machines adopt the present invention, relying on pneumatic actuators and air motors to drive the rotary dispensing valve for feeding. Through actual operation, it is proved that the use of pneumatic actuators and air motors to drive the rotary sub-packing valve for feeding has significantly improved and improved in terms of measurement accuracy, output, cleaning and disinfection, and stability, and due to its simple structure, small size, and light weight , long life, simple principle of speed regulation, etc., which greatly simplifies the work of operation and maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com