Method and equipment for measuring total solid matter content of natural rubber latex

A technology of natural rubber latex and total solids, applied in the field of natural rubber, can solve the problems of time-consuming, cumbersome operation, power consumption, etc., and achieve the effect of expanding the area, high measurement accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Operation method

[0030] 1. Use a disposable syringe to drop a small amount of latex sample into a numbered container of rated weight (including foam metal with a weight of ω 0 ), weigh the total weight ω of the sample and the vessel 1 , prepare several samples to be determined according to this method;

[0031] 2. Place the prepared vessel on the heat source in the vacuum system, turn on the vacuum switch, and make the system reach a negative pressure state.

[0032] 3. Use the temperature controller to set the heating temperature to 180-350°C, set a few minutes, and vacuum dry the sample;

[0033] 4. Weigh and measure the dried sample together with the vessel to obtain the weight ω 2 ;Use the following formula to calculate the total solid content α of the sample:

[0034] .

Embodiment 2

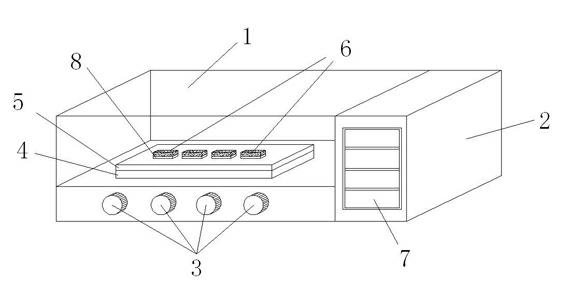

[0036] A kind of measuring equipment of the total solid content of natural rubber latex, comprise the metal container 6 that is made of metal foam of rated weight, the electric heating plate 5 of heating metal container 6, described measuring equipment also includes the described metal container 6. A sealed box 1 for vacuuming. The measuring equipment also includes temperature, vacuum and other function control knobs 3. The temperature, vacuum and other function control knobs 3 control the electric heating plate 5 and the vacuum pump 2. Control, the measuring device also includes a plate weighing system 4, and the measuring device also includes a digital display 7. The metal foam is covered with metal foil 8 on its side and bottom.

[0037]

Embodiment 3

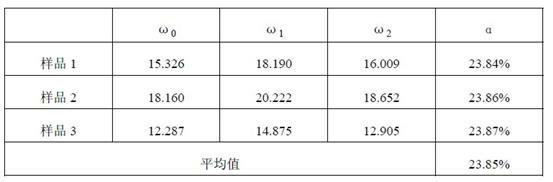

[0039] The samples were fresh natural rubber latex purchased from the purchase point of the rubber factory on the same day.

[0040] 1. Determination of total solids content by standard oven drying method: use a disposable syringe to take 2 to 3 grams of latex for determination, drying temperature is 70 ° C, time is 10 hours, and three groups of sample tests are done;

[0041] ω 0 : vessel weight;

[0042] ω 1 : The total weight of the container and latex before measurement;

[0043] ω2 : The total weight of the container and latex after drying;

[0044]

[0045] 2. Determination of total solids content by vacuum drying method (using the method of Example 1 and the equipment of Example 2): use a disposable syringe, take 0.2 to 2 grams of latex for measurement, drying temperature 200 ° C, vacuum degree -0.09 Mpa, time 3 minutes, do three sets of sample tests;

[0046] ω 0 : vessel weight;

[0047] ω 1 : The total weight of the container and latex before measurement; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com