Feeder with elevating control mechanism and multiple material spray pipes

A lift control and feeder technology, applied in the field of feeders, can solve the problems of death, hand feeling measurement errors, affecting the growth of abalone, etc., and achieve the effects of clean environment, accurate measurement and feeding, and novel and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present application will be further described in detail below through embodiments in conjunction with the drawings. Obviously, the described embodiments are only part of the embodiments of the present application.

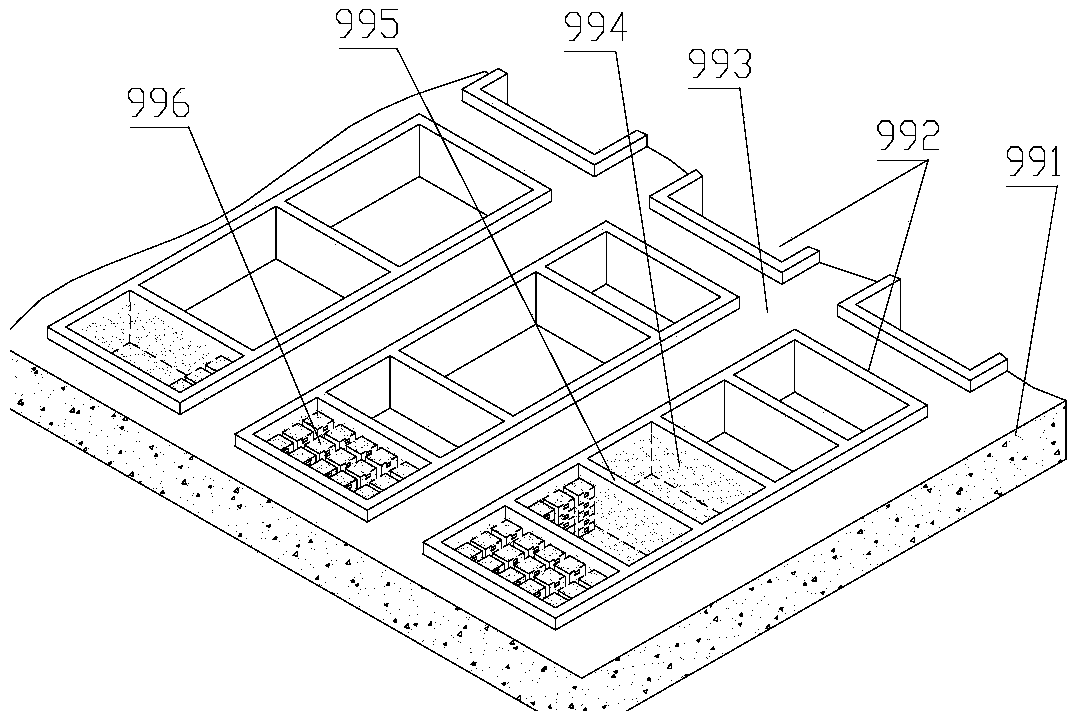

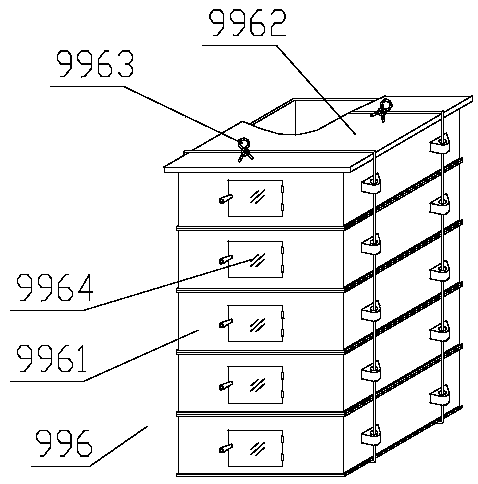

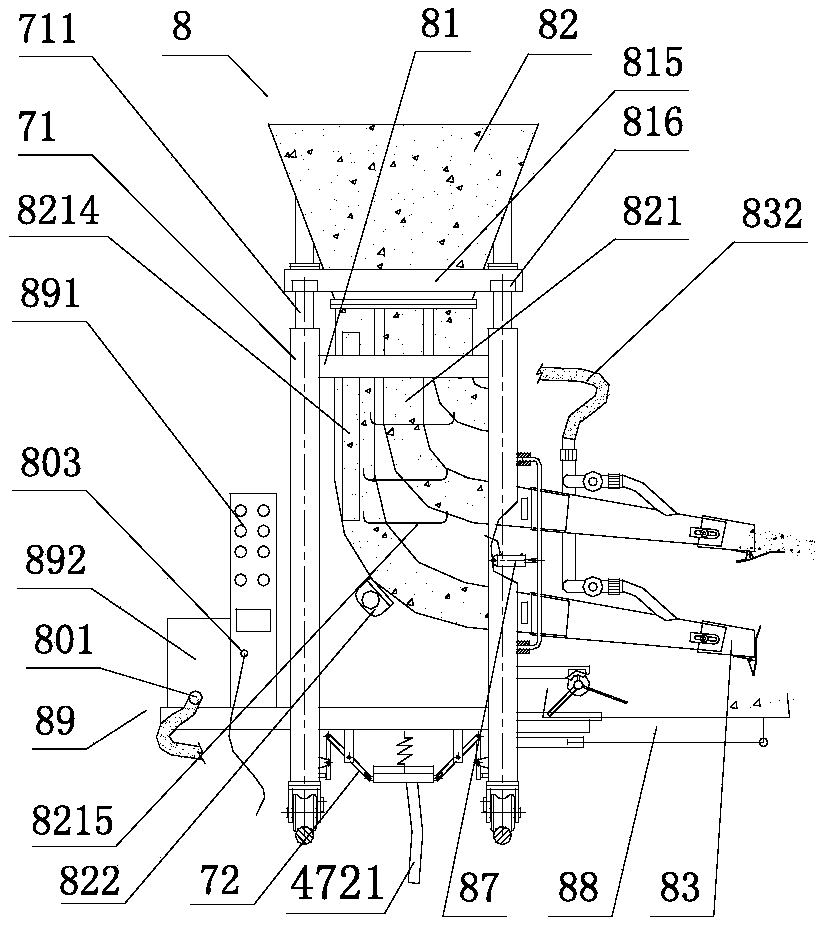

[0026] Such as image 3 , Figure 4 , Figure 5 Shown here is a front view, a side view, and a partial enlarged view of a feeder with a lifting control mechanism and multiple spray pipes according to the first embodiment of the application. The feeder 8 includes a frame 81 and a bin 82. Hopper 821, spray pipe 83, spray pipe lateral adjustment device 87, leakage receiving device 88, lifting control mechanism 72, high-pressure gas distribution system 08, water flushing system 47, control system 89; the frame 81 There is a pneumatic column 71, which can control the telescopic movement of the piston rod 711 on the pneumatic column through the internal high-pressure gas, thereby controlling the raising and lowering activities of the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com